Southerngunner

Members-

Posts

119 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Southerngunner

-

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

-

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Usually I'm a glutton for punishment as well but instead of hearing "I told you so" from the little lady for buying someone else's problem I passed on the 168W-101. I think that my next machine will be a new 441 style, if I'm going to get in trouble it's either going to be go big or stay on the porch. -

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Well I went to the shop today and took a closer look at the 168W-101. It did not have any knee or foot pedal presser lift option besides the one behind the needle bar. The front cover was missing and there was a broken off screw that would hold the plate. I had to screw around for almost an hour to get it to pick up the bobbin thread, the walking foot appeared to work properly as I got it to stitch eventually by turning the hand wheel. The drive belt didn't look like it was been replaced for several years as the edges showed some slight fraying. The owner of the shop hasn't touched it since it got there on consignment over 2 years ago and wanted to sell it as is. He did not have a belt for me to try it plugged in. There was enough little alarms going off in my head that I wasn't willing to take a chance with it ( I dont need another project that I propbably can't get parts for). It was a cool machine nonetheless and eventually I may end up with post machine just not today. It was probably worth the $250. But I did end up passing on it -

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Thanks for the explanation. -

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

What is the difference between the g and the w models ? -

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

After a year and a half of using my other machines I am comfortable enough to find my way around my first post machine. I still have a lot to learn but I'm not afraid to tear into one now and troubleshoot it. Thanks to the very knowledgeable and helpful folks on the forum, I'm sure that I will have some dumb questions before it's all said and done -

I don't think that I can pass this deal up.

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

As soon as I get it here and cleaned up the servo will be on the way if it doesn't need and other serious repairs -

I don't think that I can pass this deal up.

Southerngunner posted a topic in Leather Sewing Machines

My dealer still has this old Singer 168W-101 that I almost bought 1-1/2 years ago. I'm pretty sure that I don't need it since I already have ,a cobra 26, consew 206 rb -2, and a econosew 18"arm 29 k copy. I gave him a call today and he said that I could have it for $250.00 with the table clutch motor and light and bobbin winder. I'm supposed to go get it next week, he said he is tired of looking at it. I hope I'm not making a mistake. -

Cobra Class 26 Oil Resorvoir Pan

Southerngunner replied to rodneyv's topic in Leather Sewing Machines

My class 26 has the pan also, I believe it is a catch pan to keep excess oil from your table -

Thanks for your reply, I passed on that machine but it is still at the shop 1 1/2 years later. Every time that I stop in I'm tempted to ask about it just because it a cool vintage machine. But I am actually thinking of a cowboy 4500 or cobra class 4 to do more than my class 26 cobra can do, I also picked up an enconosew 18 inch arm shoe patcher copy of the singer 29 series..

-

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

McGyver is alive and well, us old guys are packrats and fixin fools -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

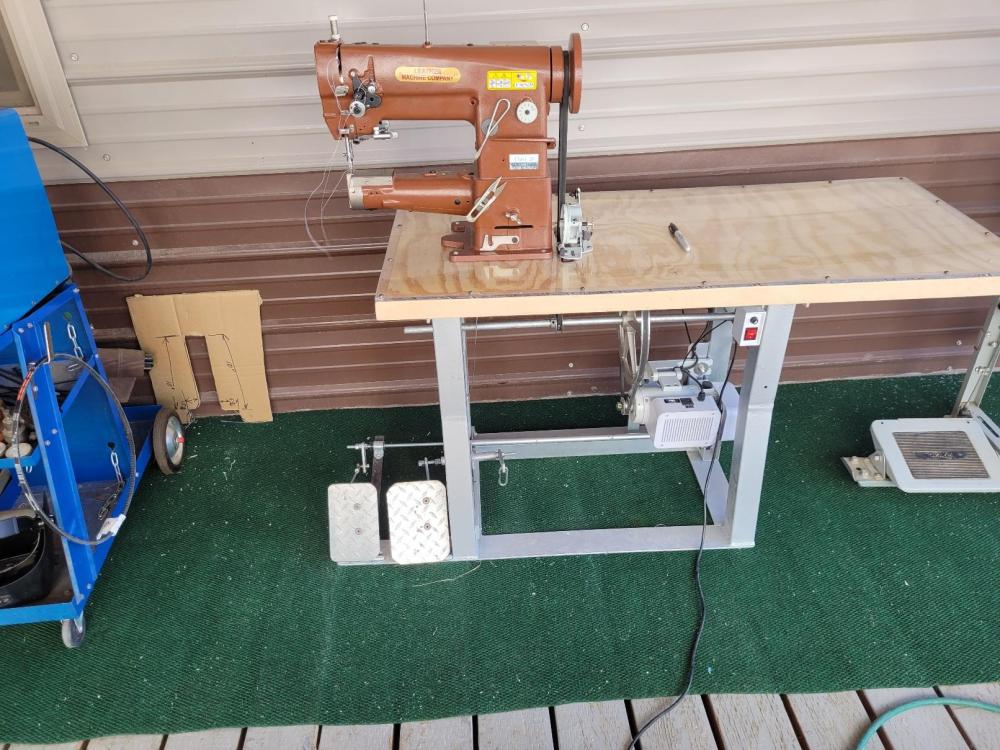

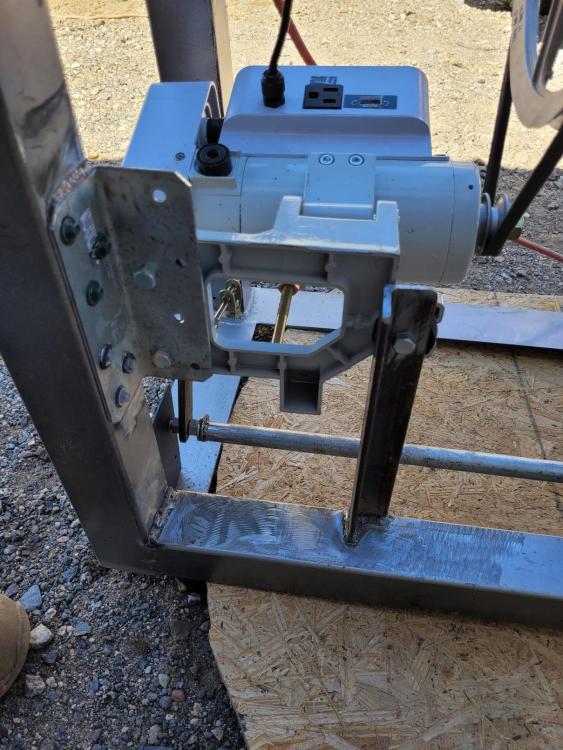

Thanks, I kinda like the look myself. I bought the servo motor, pullys,belts, and 1 sheet of 3/4" plywood so I'm in it under $300. Everything else I already had and it has been paid for a long time ago( I don't throw good stuff away) so I don't count it in the tally. Including the cost of the class 26 the total is well under $1600 and of course all of my time is really cheap. -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Maybe later but for now I am tired of messing with this thing. -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

-

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

-

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

I built a drawer and a pull out shelf. I won't be moving this much as it weighs a ton , but it doesn't shake,vibrate, or move around and the machine is solid and smooth when running -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

I have finally completed my homemade table and cabinet. My build is done except for a couple lights which has been ordered. Now I need to start sewing a bunch of scraps so that I can get used to the machine. -

Weird and frustrating obstacle Setting up shoe patcher

Southerngunner replied to Annikita's topic in Leather Sewing Machines

Everyone can't afford to drop 3 to 5 grand or more for a sewing machine. I bought one when I finally decided that hand stitching wasn't working any more. I gave it to my daughter for a no power required sticher. It took a lot of tinkering to get it to work but if you don't push the limits its a good inexpensive option to sew with.good luck. -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Thanks for the reply. I haven't touched my welder for a few years also, but after a couple passes on scraps it started coming back to me. I plan on statring to building a side cabinet today and then I need a light. I did make my own thread stand however. My wife thinks I'm nuts to take time to build something that I could order for $15.00. -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Thanks, I was a welder/ fabricator/ heavy equipment mechanic for 45 years. It felt good to do some welding after a couple years of not working with metal. -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Yep I can turn up the adjustments on the servo for speed and still be able to go 1 stitch at a time when needed. -

Almost done with my Sanford & Son table

Southerngunner replied to Southerngunner's topic in Leather Sewing Machines

Yes that is a factory K -leg table next to it. I just wanted to prove to myself that I could make a usable table. -

Well here it is so far, I still have to make a side cabinet for storage . At this points it is usable the way it is. The top is 2 pieces of 3/4" plywood glued and screwed with a border of 3/4" Birdseye Maple. The replaceable top is. 1/4" Lexan ( an old windshield from a Yamaha Rhino) I set up a 12" and 2" pulley system and a Consew servo motor to drive my Cobra class 26 at a controllable speed with gobs of torque. Most of it was built with stuff that I had hoarded because it was to good to throw out. Comments are welcomed Here is a couple more pictures

-

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with:

-

- 181 replies

-

- diy sewing table

- industrial sewing table

-

(and 3 more)

Tagged with: