Nico619

Members-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Nico619

-

Singer 18-2: can't get the tension right

Nico619 replied to Nico619's topic in Leather Sewing Machines

The two threads are actually identical. Same brand and same thickness, just different color. The dark brown i used earlier (for the bottom thread) was thinner, and in both cases the result is the same you see. I tried the marker thing on the needle and now it's right in the middle. I'm starting to think.. What i'm testing it on right now is a box calf leather (a bit more rigid, around 1.4 mm) on top, and a tumbled goat skin at the bottom (0.8 mm, for shoe lining). Is it possible that even if the tensioning was completely perfect, because of this leather it would still show the top thread a bit? Maybe the needle opens up the soft leather too much and no matter what it shows the top thread.. what do you think? -

Singer 18-2: can't get the tension right

Nico619 replied to Nico619's topic in Leather Sewing Machines

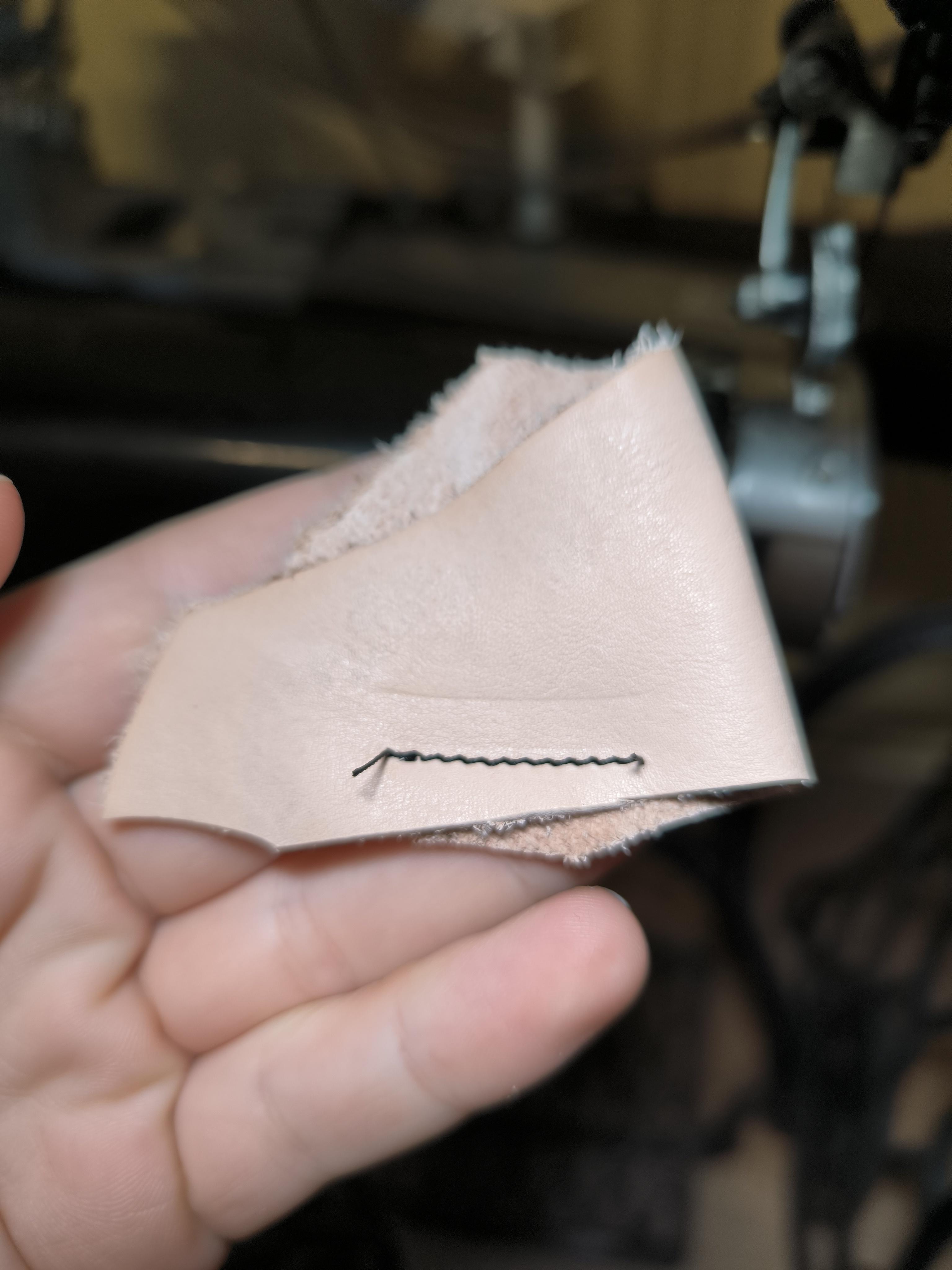

Alright, i've done some modifications, that is making the check spring tighter (i think it's bouncy enough now. Earlier it might have been looser) and changing the needle height. When the shuttle hook was passing next to the needle's dig, it'd be at the very bottom of it. Now, as you see in the video, it's right in the middle. I also loosened a bit more the bottom tension and tightened the upper tension (check the pics). Despite all that, the top thread still shows up at the bottom. In the picture the black thread is the top one. The light brown one is the bottom one. I put the video and the pics on this imgur link: https://imgur.com/a/ArIpoUj Any ideas what else could cause it? -

Singer 18-2: can't get the tension right

Nico619 replied to Nico619's topic in Leather Sewing Machines

Thanks for the answer. I checked the manual earlier today, and the top thread routing seems to be done just like in the manual (i posted a picture above, if you want you can check). How would the needle height influence the tension thing? Nicola -

Hello everyone, I bought a few months back a 100 year-old Singer 18-2, in very good conditions, and i've been using it since then. The machine stitches very well, but I still have a problem with getting the upper and lower tensions right. In particular, every time i use it, the upper thread seems too loose at the bottom. I'll add as many pics as i can to show the problem and the conditions of the machine. As soon as i got it i replaced the spring in front of the tension disk (the one that goes up and down with the thread) with a new one. Since the top thread is visible at the bottom, i tried to tighten the tension disk by a lot, on top of loosening the bottom tension on the shuttle. That didn't solve the problem at all though. In the pictures the black thread is the top one, whereas the brown one is the bottom one. You will also see that the tension isn't that tight in the picture, but i also tried, as stated above, with a much much tighter setting, while still not getting the problem solved. I'm starting to think that the reason might be something else, but i don't know what. Thanks in advance for reading through it.

-

Singer 18-2 looking for information on a screw

Nico619 replied to Nico619's topic in Leather Sewing Machines

Thank you all, i found those screws for sale and i'll soon order them.- 5 replies

-

- replacement

- parts

-

(and 3 more)

Tagged with:

-

Singer 18-2 looking for information on a screw

Nico619 replied to Nico619's topic in Leather Sewing Machines

thank you very much! the ones i bought that were on the seiko tf parts list were indeed the 15/64" x 28 TPI, which are too big. The other option you gave me seems to match the screws that are in there now, so maybe they'll work. I just need to find them now.- 5 replies

-

- replacement

- parts

-

(and 3 more)

Tagged with:

-

Hello, i recently bought a Singer 18-2 machine, and i need to change the two screws on the wheel bar (i'll post a picture of which ones). I bought the screws used for the seiko tf series, however they're too big. I found a parts list for the singer 18-2, but it doesn't mention the size of the screws or anything that can help me to track it down.

- 5 replies

-

- replacement

- parts

-

(and 3 more)

Tagged with:

-

Upper thread gets stuck in the bobbin case. Any ideas?

Nico619 replied to Nico619's topic in Leather Sewing Machines

Well, I'm glad that's a common problem, it makes me feel less stupid haha I tend to use pretty common words as well, however every once in a while my mind kicks in and gives me some rarer and more specific words, that was the case :D -

Upper thread gets stuck in the bobbin case. Any ideas?

Nico619 replied to Nico619's topic in Leather Sewing Machines

that might have contributed to it. As a matter of fact i have followed the same video before and after, but maybe the thread got off the tension disk and that exacerbated the problem -

Upper thread gets stuck in the bobbin case. Any ideas?

Nico619 replied to Nico619's topic in Leather Sewing Machines

@CowboyBob yes, I'm holding the thread at the start. I think I have finally solved the problem! I'm not sure what exactly was causing it, but I mainly did two things: -I rethreaded the whole machine. I had already threaded it in the past with no problem, but maybe this time something was wrong with it and rethreading it solved a tension problem. -I had noticed that the roller foot was slightly in the way of the needle, causing it to infinitesimally bent. So i added a washer to have the roller foot move slightly to the left, to avoid being in the way of the needle. -I also added some oil in the machine. It was supposed to be already oiled, and it probably was, however I added some more in case that was the problem. I ran a few tests with various thicknesses of leather and so far i haven't gotten this problem again. Thank you anyway for taking the time to read it this far! -

Upper thread gets stuck in the bobbin case. Any ideas?

Nico619 replied to Nico619's topic in Leather Sewing Machines

NO PROBLEM: https://imgur.com/a/0YczOWe PROBLEM: https://imgur.com/a/RJD4sCs here is a video of the upper thread getting stuck: https://imgur.com/a/WU6zqsl now they should work. -

Hello, I recently bought a Necchi 910-159 sewing machine (should be a pfaff 191 copy), and for some reason sometimes when i start sewing, slowly pressing the pedal, it doesn't start, and you can hear the motor becoming louder and louder, almost as if it's too hard for it to go through the leather. But the thing is that the needle hasn't even moved from the top position, so it's not because of that... I'll post two videos, one in which the sewing machine works normally, and another one in which it gets stuck. After hearing the motor becoming louder it suddenly starts sewing at full speed, which is the problem i want to solve.. NO PROBLEM: https://imgur.com/a/0YczOWe PROBLEM: https://imgur.com/a/RJD4sCs I've analized the sewing machine in the past few hours and i think i might have found what causes the problem. I first noticed that it was not a motor problem: the increasing sound is caused by the bobbin being jammed by the thread. Now, at first i thought it was the bobbin thread, being not properly winded or something along those lines. However after a few tests and rewindings i started noticing that it probably was the upper thread.. I then used two threads of different colors, and as i assumed, it was the upper thread which for some reason winds around the bobbin case, causing this jamming which causes that sound by the motor, since it can't freely move the lower thread. The super fast sewing right after that happens because, i assume, the motor is finally able to break the jammed thread and sews at full speed... So now i'm pretty sure this is the explanation, however i have no idea how to solve this upper thread jamming around the bobbin case. here is a video of the upper thread getting stuck: https://imgur.com/a/WU6zqsl

.thumb.jpeg.45ec98686445b6dc11866fc224ce19e0.jpeg)

.thumb.jpeg.7eced81d18e2613c4d45aa75ff4ca603.jpeg)