Search the Community

Showing results for tags '45k'.

-

I recently got a Singer 45k25 machine up and running. Ive got a standard presser foot on it now. Works great. However, Id like to try out a roller foot. Unfortunately, I can't find one anywhere. Does anyone have any leads on where to find one? Could I fit one that is meant to go on another sewing machine? Anyone selling?

-

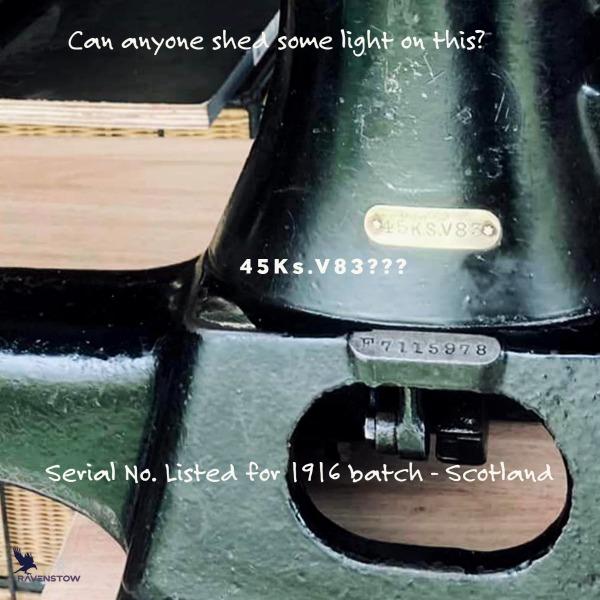

As mentioned in another section of the forum, I acquired this 45Ks.V83 last week from FB marketplace. Made in 1916 with three generations in one family, I was so damn excited to find a machine preserved in almost working order. Was also fascinated as the seller shared their family story. I had been looking for a cylinder arm to assist with my work for over eight months. Being an avid Singer fan for over 30 years had me scrambling to make to 1100km trip to pick up this beastie. The renovation went well. Before I had picked up the machine I had some vague dreams of mounting it back on a treadle stand. Two things brought this to an end. 1) the weighted flywheel on the original stands is very rare here in oz. Found some stands but alas not the 2 or 3-geared wheel. 2) when I got the machine the motor and gearing setup was endearing for its history and age. The cast iron stand was also an Australian-manufactured frame. Some questions I hope to share and explore with the talented brains trust here = 1) Can anyone shed light on this version?? 45Ks.V83? The 'V83' is not listed in any archive I can find from Singer at the time (serial no. lists it from the Clydebank Factory. 1916. One of 1500 45k. Quite a big batch. Gearing up for war manufacturing????) 2) Any light on the 's'. Had assumed it was 'Saddler' but only as I had seen it in the factory inventories occasionally. As Stewey mentioned this is unlikely as most of these would enter the saddlery trade regardless. Agree that it could mean 'special' but am wondering is others might have insight. 3) the rectangle work plate has also been hard to find in manuals and catalogues from the time. Stewey also mentioned he had these on his. Is it possible that these were for the Australian market or do others have these plates?? Oval is listed in special order lists from the period. Anyhoo... Adding images of the reno for those interested in the Singer 45K and the next person who might be looking for anything on these wonderful leather stitchers. . Big thanks for this site and the effort everyone has put in to support the community and subject. All the best. More progress pics And the last

- 9 replies

-

- singer

- renovation

-

(and 1 more)

Tagged with:

-

Hello all, I am a frequent visitor to this forum however this is my first post. As well as an active leather worker I am also a keen collector of industrial sewing machines. I recently picked up a Singer 45K (I'm not sure what subclass as the brass plaque is missing or has been removed. The serial number AE190567 indicates that its from around 1935-1938, it has a jump foot and no reverse). Its in good condition in the main part with one exception - I significant bend at the drive end of the oscillating shaft (part number 91171). The bend is binding up the oscillating roller in its guide. My question is does anyone here have a spare oscillating shaft (part :91171) that they would be willing to sell? If not I will have to try and repair the shaft which would be tricky or machine a new one. Many thanks. Josef.

- 22 replies

-

When I placed my 45k on it pedestool stand, I used an industrial M belt to drive it. over time this has twisted to run an edge inside the groove. I thought I would replace the belt with a round leather belt and souurced some 8mm ( or 5/16") belt (same as my Landis outsole stitcher) but it feels too big. Should I use 8mm or go down to 6mm ( or what ever I have on the 29k patcher)? Thanx Matthew

-

I have a fair number of bobbins. I created and 3D printed holders for my K6 & 45k bobbins. They are available on Thingiverse if you want to print some more. https://www.thingiverse.com/thing:4910646 https://www.thingiverse.com/thing:4896562

-

I would like to add a binding plate to my bigger sewing machines. on the 45k, I believe the Guide plate is P/N91168 and the screws fixing the plate are P/N #180f. can any one confirm these are 3/16 x 28tpi screw? What would be the screw needed to attach the binding plate? would these screws also fit the 132k6? Thank you Matthew

-

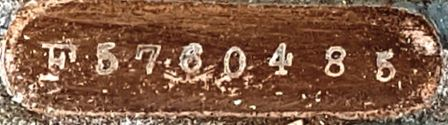

Hi everyone, I have a Singer 45K58 with the serial number F5760485 (at least that is what it looks like). From http://ismacs.net/singer_sewing_machine_company/serial-numbers/singer-f-series-serial-numbers.html the number matches a 45K from early 1914, which is a wee bit confusing as I would have expected its listing to be 45K58 rather than a generic 45K? Also the machine looks more modern than the ones of that era that I have seen, and is finished in hammered blue/green, rather than black. Any help, enlightenment or suggestions welcomed Thank you, Harry

-

45k58 First machine of this class. Never used or serviced a large oscillating bobbin machine. Managed to find user manuals - is there a service manual available? Is the timing pinned i.e not something I ever need to worry about - like some class 15 clones? If I remove the hook assembly for cleaning/servicing will timing get put out? There's 1 large screw beneath the 'race' - is it undo that and let it all fall forward? Any guidance on the foot spring adjustment - looks like you can sort of make it walk? Pressure spring mechanism on top looks quite complex - what's going on? Thanks, folks. Service manual? or manual close enough to give me a head start? Is it similar to a 132?

-

Hi Everyone, I've been lurking around for a few years now but haven't asked any questions because I've always been able to find a thread with the information I'm looking for. I have found a few threads discussing Singer 45Ks but none specifically about the 45K52. I've been making belts, wallets, gun holsters, card cases, knife sheaths and dog accessories for about 5 years. I feel like it's time to turn my hobby into a business, which is why I bought this machine I picked the machine up over the weekend. The guy who was selling it bought it to fix horse blankets and harnesses but ended up with some health problems and can't operate the machine anymore. I was able to thread it, based on the 45K manual that found on the forum, and run the machine before I bought it. It's obviously an old machine but in great shape and had been recently re-built and tuned by a professional Industrial sewing machine repair man. People in the area swear by this repair man but so far I haven't gotten any response to my phone calls. I'm pretty sure, from my reading, that it should be a decent machine for belts, dog harnesses and leashes, and maybe knife sheaths and gun holsters too. My questions are: Do I actually have it threaded correctly? Depending on the leather I'm putting through it, it sometimes pulls the knots through the bottom or top of the leather. Is this a tension problem? It will only make an actual stitch at the slowest crawl. If it picks up any speed the thread breaks. Could this be a tension problem or something else? How do I set the tension? After looking through the manual that I found here, and then inspecting my machine, I think I'm missing some features that other 45Ks have such as: reverse and adjustable stitch length. Does this machine really not have an adjustment for stitch length? What is the wheel to the lower right, near the belt? Is it a bobbin winder? Finally: what kind of foot does it have and should I get something different? Thanks for all of the information that I have picked up here over the past few years. I hope you all can help me out with some of these questions.

- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

I have for sale a 45k21. It is a nice looking machine except it is worn out. I installed a new shuttle in it and it still will not sew. I tried to get it to sew but to no avail. The photos show some of the problems with the machine. The "green" photo with the red circle is a tapered screw with a tapered flat spot to locate the part it holds in place this was installed incorrectly. I took the screw out and realigned the parts and put it back together. The nut in the middle photo is the opposite side of the tappered screw. Just to the left of the nut is the end of the rocking device for the shuttle drive shaft. This screw is not missing. If you remove the screw the shuttle can not be retimed. There is a tapered drive pin to the left of the screw. The only way to adjust the shuttle timing is to remove the drive pin and reinstall the screw and use the screw to hold the shaft. The new shuttle brings the hook to the middle of the needle after moving the 3/16th inch up to retard the timing the hook in just 1/16 inch to the left of the needle. This position does not allow time to form the loop to sew. Thas is as far as I have gone and am going. This is the 3rd week trying to fix this thing. I have had enough. I did find some screws and parts that are worn and parts installed incorrectly. Some one tried to fix the machine before I bought it and failed. They probably had the same problem I have. I can't find parts for the machine. So I would like to sell it as a parts machine. It is missing the wax pot, the lifting arm for the pressor foot. It has a bobbin winder on the right side of the machine. I will take some pictures and post them. The head only is for sale not the table. I would like 350 for the head plus shipping. Thank you for your interest.

-

I love my Singer 45k25, but at time it is just too much, as it struggled with light stuff. As I decided to make a couple of leather garments and needed something a little lighter, able to sew 1.2mm leather and textiles. I found a Juki DDl-555 for $100 and 1/2 a tank of gas to pick it up. At the saem time I found a Consew 206RB but for $1500 versus $100, hmmmm let me think. The Juki has not even been run in, no paint wear and al I needed were some bobbins and I decided to give it an oil change just in case. Yes, it is textile machine and yes it runs like a belt fed, but is very controllable at slow speed, though I have 45mm pulley on order to replace the 105mm currently installed. But man it makes a nice stitch, every stitch forever. very nice. In light garment leather the photos speak for themselves. And this is with standard 100 size textile sharps, as my leather needles are int he post. The point is, that while NOT a leather machine, it is a bargain professional textile machine that has a lot of offer the light weight leather engineer. Besides, $100 for the beautifully engineered unused machine could not be passed by. Tony

-

I am looking for a working Singer 45k Cylinder arm machine. Would prefer it to be in the Pacific Northwest. Please post pictures and price.

.thumb.jpeg.08163a1ca5bf8936b7e40c3c7b2a7bf8.jpeg)

.thumb.jpeg.f17dbda3ff723c13c729ce9518bc2045.jpeg)

.thumb.jpeg.e63385c9768b2267b7531996e360bb20.jpeg)