Search the Community

Showing results for tags 'edge finishing'.

-

I'm focused on my edge work. I'm now using refillable Montana 15mm markers: https://www.amazon.com/Montana-Acrylic-Empty-Marker-045475/dp/B006ZM19P2/ref=sr_1_5?crid=7G3KERUURFSE&keywords=montana+refillable+marker&qid=1664026879&sprefix=montana+refillable+marker%2Caps%2C339&sr=8-5 I use these to apply water, liquid saddle soap, full strength Flebings Dye and now am considering using a refillable marker for applying resolene in my last step of edge work on 12-14 ounce belts. I use a dremmel burnishing wheel in between applications to smooth the edge. I'm not at the glass stage with the natural, no dyed edges yet. I burnish with the dremmel then finish the pass with denim. Do you have any good or bad comments on using the marker to apply resolene? I'm using full strength. Do I dilute it or is a simple full pass or two the way to go using full strength. Guidance to include failures requested...along with your successes. -Joe

-

Prepping for a run of belts with 10-11oz. Wickett & Craig Traditional Harness Leather. Wondering who has had success with burnishing the edges with these hides, as I've heard they can be tricky?

-

- edges

- edge finishing

-

(and 1 more)

Tagged with:

-

Hello all, new to the forum and new to Leatherworking in general. I have a couple questions about making my own suede weightlifting belt. First is if sandwiching veg tan between suede what's the best edge treatment? From what I've read Fiebings edge coat, Giardini or Fenice is the route I want to go. Second is what variety of weights should I use? For strength and rigidity should I use 9oz veg tan and 2 layers of 3-4oz suede or do 2 layers of 5-6oz veg tan and 2 layers of 2-3 oz suede. General thickness should be 1/4- 3/8". Attached is a picture of what I'm shooting for! Thank you for your time and feedback!

- 10 replies

-

- suede

- weightlifting

-

(and 4 more)

Tagged with:

-

Hello, I am having a small problem finishing the edges of Sedgwick English bridal. I bevel, sand, burnish with water and soap, dye, then apply a finish. For the final finish I have tried bee's wax and pearl glue (a traditional English technic). I have of course tried other methods and the order etc. I am not new to burnishing (but I am new to English bridal) and can get great looking results. What I am concerned about is wear. One thing that has been recommended to me is to use tallow fat as a filler/burnishing gum. I just can't find any at the moment Here is my problem: The edges look fantastic! Smooth, great color and shiny. But...it seems they simply will not last. After a day or so of normal use, parts of the edge seem to dry out and then the edge get fuzzy or slightly rough again (especially around the buckle). It is not bad, it just doesn't look 100% anymore. I want my customers very happy and don't want the belt wearing after a week of use. I am currently waiting to see how my latest attempt will hold. Is this normal? Am I just being overly picky? Any ideas on what I may be doing wrong or how I can resolve this? Thank you for any help you can offer! -Adam Here are some photos of how my edges look when "new" Sorry but I do not have a photo of the problem I mentioned. I will try to get a photo when I get a chance.

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

Just finished up a dual color bifold card case .. as it was 2 colors, I didn’t want to burnish the edges into a single edge.. I do not have gum trag, so I applied a home made concoction to the edge and used some flannelette cloth (for cleaning firearms) to rub the edges.. at least it kept the 2 distinct colors

-

Hi Everyone! I have been working on my strap edges for a while now, and I'm still frustrated with the result! I still get some fraying here and there that feels rough on my shoulder. I am looking for a Filson-like supple finish, as seen in the photo below. Anyone have any tips or do you know how they achieve this result? Are these straps burnished and painted or do they use paint and an electric creaser? Thanks very much in advance for your input!

- 4 replies

-

- edge finishing

- straps

-

(and 3 more)

Tagged with:

-

Hey guys, I've been making a few passport and card holders and for my last one I decided to line it with some Tandy Premium Mission Grain Pigskin Lining Leather, I glued it to the main piece and then trimmed the excess, I assembled and stitched everything and then burnished the edges, I usually get a smooth and clean edge but this time, with the lining, it looks like it's cracked, as you can see from the pictures I've attached. I'm not that familiar with pigskin, I'm guessing this particular piece is not of the greatest quality and that may be the reason why I can't burnish it very well, I'm from Portugal and before I bought this piece from Tandy I bought a piece from a local shop, it was really cheap but seeing as I had never bought pigskin before, I thought I was getting a deal (I'll attach a couple of photos later), when I got home I took a good look at it and it was kind of flimsy and had a greyish color to it, I also tried dying it just to see the results and it didn't turn up very nice, I wanted to know your opinions and if it's just the quality of the pigskin or if I should be using another technique! Thank you very much, Lourenço

- 10 replies

-

- edge finishing

- pigskin

-

(and 2 more)

Tagged with:

-

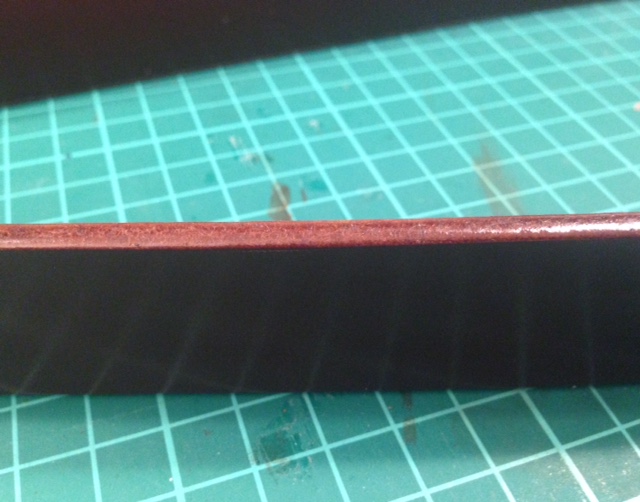

Hi folks, the time has come to reach out directly to the collective knowledge that is assembled here - just couldn't find a solution via search and Christmas is nearing meaning order have to be fulfilled! I am currently facing two types of material issues that I'd like to share with you: The edge of a finished edge splitting open [1] and the surface of leather belt straps wrinkling/cracking after dyeing [2]. [1] Edge splitting Background: So I got this very fine veg tan hides for smaller leather goods - they come in .8mm, 1-1.3mm as well as 1.3-1.5mm thicknesses and dye really beautifully. The leather breaks in just like it should and it holds the dye nicely. Issue: All is great but the edges. My standard routine for edges would be (all Fiebing's) - saddle soap - gum trag - edge dye with the help of a wooden burnisher on a post drill. On my other leathers this procedure works fine and gives a nicely finished edge than holds. With the mentioned veg tan it gets to what you can see below. When using compound bees wax I got the edge to become more solid to hard, which is "closed" but not as nice.. Any recommendations are highly appreciated! [2] Belt wrinkles/cracks Background: Got a veg tan hide some time ago which is around 3mm in thickness. Cut it in straps, made the brown belt you can see below and stored the rest until now. I dye using Fiebings Oil Dye and finish with Neatsfoot Oil as well as Carnauba Creme. Issue: The undyed hide wrinkles when bending or rolling "against" the top-side. The dyed belt wrinkles and kind of pushes the skin and stays as seen below. When bending backwards e.g. stretching the top-side it can crack. I tried to contact the leather retailer I got the hide from to ask if they had any issues with the lot I got my hide out of - only thing I received was an unfriendly email back asking what I wanted of them after a period x with no new orders. Any ideas on how to make the leather softer or treat the surface? Also, ideas for probable causes? Looking forward to your valued opinions, taobao

- 2 replies

-

- edge finishing

- leather cracking

-

(and 1 more)

Tagged with:

-

Hey guys, I've been painting my edges with the same Fiebings Pro Oil Dyes that I use for my projects and was curious about the difference between the Pro Oil Dyes and Edge Kote, I've never used Edge Kote so I have no experience with it! Thanks for the help. Cheers, Lourenço

-

Hi All, I have been having some issues with discolored edges and I am trying to figure out the cause and how to avoid them. After I burnish my edges, dye, and finish my piece, I am noticing discoloration near the edges. See the included photo, specifically along the edges near the Nerf blaster. The dye doesn't appear to take as cleanly near the edge as it does on other portions of the leather My burnishing process was adapted from Bob Park's tutorial here on Leatherworker.net based on what I own. Steps I am using are below: 1) Bevel and sand my edges, 2) Wet the edges with water 3) rub glycerine soap into the edges 4) burnish by hand with canvas until edges are smooth I am applying Fiebing's Professional Oil Dye via wool dobber when dyeing. I am seeing the issue with Dark Brown and Saddle Tan, but not when using Black. The dye is not penetrating despite several carefully applying several coats of dye. My best guess is I am getting glycerine soap onto the surface of the leather when I am applying it to the edges. Or perhaps I am accidentally burnishing a portion of the top of leather as I am rubbing the edges with the canvas cloth. Before I have been dyeing, I have been taking a look at the surface of the leather and I am not seeing any obvious signs of excessive glycerine soap residue or inconsistent texture from over burnishing. I am stumped. Has anyone encountered this issue and can you give me feedback on how to avoid it?

- 3 replies

-

- burnishing

- edge finishing

-

(and 2 more)

Tagged with: