Search the Community

Showing results for tags 'reverse'.

-

Hi all! I'm brand new to machine leather sewing so please excuse any stupid questions I bought a Seiko STW-8B - which I have since found out is often sold as a Consew 266R. It was sewing OK but had some issues with reverse stitch length which I think I solved by replacing an after market bolt which was fouling on the main shaft. I now have forward and reverse hitting the same holes - which took hours but was worth it I think. I have also fitted a servo motor as clutch control is apparently wAY beyond my skill level :D I still have a few issues which I would really appreciate some advice on. I'm going to list them all in one topic but happy to split if moderators prefer: Presser foot height and needle bar interference From watching @Uwe's brilliant video series I can see that it is possible to sew through 3 layers of 8/9oz veg tan - I would love to try this but I cannot get the presser foot adjusted high enough to even fit the material under. I have tried all the adjustments I could find on this site and elsewhere but it seems to be maxed out at around 9-10 mm on the knee lift even though the manual suggests it should be 0.5 inches - i.e around 13mm. Even when I do get 10mm of leather under the presser foot, when I try to cycle the needle, the needle bar fouls on the vibrating foot - I'm only using hand power to test this but it seems there would be interference and damage if I tried to run it under power. I have the standard 135/17 needle - do I need a longer needle and then adjust the needle bar higher and reset the timing? The vibrating presser foot seems to be off centre in relation to the needle. The needle sits dead centre in the feed dog hole but if I line the vibrating foot up straight in the middle of the lifting foot, then the needle is very, very close to the left edge of the vibrating presser foot hole. I can remedy this by rotating the vibrating foot slightly to one side so it does not run true from front to back - but surely that isn't correct? The timing seems to be correct (seems!!) but in reverse it is skipping stitches every time - and I'm pretty sure the top thread is just being missed by the hook. Is there anything obvious i could have messed up or do I just need to check the timing again? Thanks so much for your help - I only discovered this website a few days ago and I am hooked - so many helpful folk out there! Mb

- 17 replies

-

- presser foot

- reverse

-

(and 2 more)

Tagged with:

-

When I was adjusting things on my adler 69, I've got problems with reverse stitch. After finding solutions on youtube I've made some adjustments, but I've lost the stitch length.... Two days I was struggling with a reverse mechanism, and I've found something strange - the plate, covering a slot in which the reverse stitch lever was moving, was smaller than the slot in the cast itself... reverse lever was stopping on the plate, while there was a place to travel a bit more. I've cut the plate more, to fit the slot in the cast. Now the machine works fine on reverse with full stitch length. It's quite possible that the plate have been replaced in the past, but maybe this hint can help someone. On the photo there is a mark showing where the slot was ending before cutting it to the bigger size.

-

this machine is in great condition, it sews great as well. it is a singer 7sv76, i am looking for $2000 OBO. i also have several other 7 series singers, 7-34 and 7-33. if interested in any of those i can get pictures.

-

My new toy, the Adler 205/370 with Efka variostop is now in my living room. I am taking the main parts off, as the table needs modifying.It was not quite up to the travelling. Also I will not be using the Variostop and pneumatic stuff. I have taken off the Camozzi air operating cylinders for reverse and foot lift. The reverse lever now does not stay in place. The parts book shows a detent ball and spring thing for the zero or neutral position. I cannot see anything else in the parts book that is used to keep the reverse lever up. Is friction between the plastic block on the lever and the plastic faceplate supposed to do the job? Or what parts am I missing?

- 3 replies

-

- adler 205/370

- reverse

-

(and 1 more)

Tagged with:

-

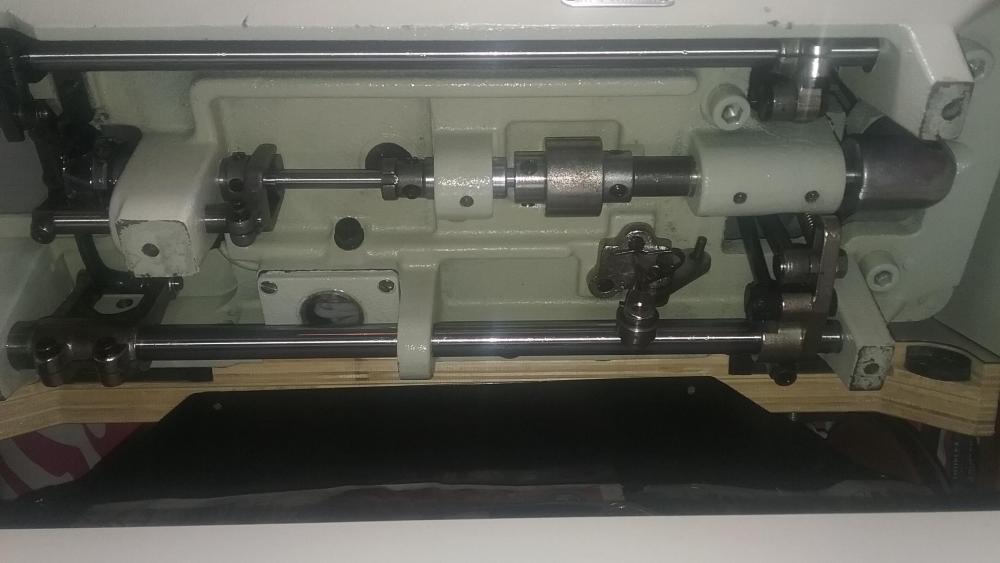

Hi all! I'm needing your help again I have a Seiko STH 8BLD 3, which looks exactly like a Consew 206rb5. So here is my issue and I have no idea if this has anything to do with it or not, but I put a speed reducer on it and that is when the problem began. I don't know if it got off track just from being handled while putting the reducer on or what. But my reverse stitch length is too long and doesn't go into the holes, it veers off a little bit and seems like when the needle is coming up, it sort of pulls as the stitching is looser and you can hear it. I have searched the forums and can't find anything that addresses this, and followed the instruction is my manual, but it doesn't help. I watched Uwe's awesome video and used his template, but it was on a Juki and looks totally different from mine underneath. But I found what I thought was it, but after trying the procedure and it didn't help, I found out from my manual that I was adjusting the wrong thing. So I put it back it it's normal place. These are the two dots that my manual says to make even and it should fix it, but it didn't. Can anyone help me? Thanks in advance! Also this is what mine looks like underneath.

- 11 replies

-

- reverse

- reverse stitch

-

(and 1 more)

Tagged with:

-

Hello Ladies & Gentlemen! New here but have been following the forum for awhile now learning a wealth of information! Appreciate all the knowledge that has been shared here. I'm hoping someone can chime in and help me understand the issue I am having with my Singer 143W3. When feeding in reverse the stitch length is shorter than feeding forward. Of more interest, when in reverse the material moves away from the operator a small amount before moving towards the operator. On the contrary, when feeding forward the material only moves away from the operator (no back and forth motion as seen when running in reverse.) I have verified that the feed dogs are indeed still moving in the "wrong" direction when they protrude through the throat plate in reverse, of course correcting and proceeding with a normal reverse feed. I have tried playing with the feed dog height to see that was grossly out of spec and causing the issue, but as suspected, it did not effect the issue. I'm not sure what the feed dog timing is supposed to be on the machine, but it appears that the first point in which the feed dogs remain stationary while actuating the reverse lever is when the needle rises 7mm above it's bottom point. Is there an adjustment to reconcile this issue I am having? May this be a clue that something seemingly unrelated is not set correctly? Truly appreciate and help or advice that can be shared! ST

-

My Ferdco 440 is sewing in reverse. I have no idea why it is doing this and I don't know where the switch is. Can anyone help? Thanks!

- 8 replies

-

- ferdo

- sewing machine

-

(and 1 more)

Tagged with:

-

Please let me start with "Hello", and I'm sorry for the bother.... I started this journey a year ago and found leatherworker.net when first searching online for " sewing machines that sew leather" Since then I have purchased a SINGER 212g140 ( but only set up as a single needle ) and a SINGER 29-4( an old patcher in good working condition!) ( that I cannot get to sew a straight line so I just keep because I think its awesome:) I sold my truck to purchase supplies and leather to start a business to help support my special needs daughter ( I am still employed, my husband is employed, and we have two other vehicles) I knew one day I would have to stay home with her, which actually happened 5 months ago when she fractured her skull. I am very fortunate to be able to work from home now- but it is difficult at best to leave the house with her to learn anything. My biggest adventures out of the house are trips to Tandy on Saturday mornings:) I literally knew NOTHING about sewing or leather or my chosen craft when I started this journey.. my ultimate goal was to make supplemental income to fund special schools and therapy that I knew would be needed. ( I refuse to let others pay for my responsibility when I am capable of doing so myself, ie tax payer money....)This was what made sense to me. I wasn't going to try a pyramid scheme or selling avon if you know what I mean. It had to be working from home, so forgive me if you are wondering " why the heck would she choose this without existing skill or a source of apprenticeship?" Any who, here I am, a room full of top quality leather, much custom ordered, when I decided that if I was going to finally take the big leap I had to purchase a top quality machine made for this purpose. A walking foot with NO ISSUES OR SERVICE NEEDED. With REVERSE. So I bit the bullet and ordered a brand new CONSEW 206rb-5. It arrived Tuesday, smelling of oil and with its test strip of fabric underneath its feet. After setting up, I began to sew( although intimidated and Leary of injuring the beast) and to my dismay a few things... ( here I finally get to the point... but please understand I am self taught, have read every manual, searched every thread, and every available youtube video.. and am still at a loss and begging for your expertise...) In reverse it seems to twist and loop its thread?!? and barely get into the same holes? I thought this machine could accurately pierce the same holes made when sewing forward directions???? It looks like crud! And I am far to inept to correct the issue myself:( Now I am reduced again to twisting my work backwards to back tack, which is what I purchased this machine to avoid. Further, GOOD GRIEF the amount I have had to tighten the top tension when switching to 2-3oz leather ( doubled up to make 4-6)!!!!!!!!!!!!!! And If I backtack more than once the top thread breaks!!!!!!!!!!!!!! WHAT AM I DOING WRONG??? Tears flowing.......:*( I just cannot see why I would have to adjust the bobbin tension, and certainly I do not know more that the dealer that set it up! I had to adjust the top because the bottom thread lies flat across the bottom on the thick leather. Using 69 bonded nylon thread top and bottom, dpx17 needle, and tears to lubricate ...sigh... thank you for any help you can offer. I know that no one wants to feel bad for someone with a brand new machine, more like I don't deserve it if I cannot operate it properly. I know its my error, but have no one to teach me.

- 18 replies

-

- consew 206rb

- reverse

-

(and 1 more)

Tagged with: