Search the Community

Showing results for tags 'split'.

-

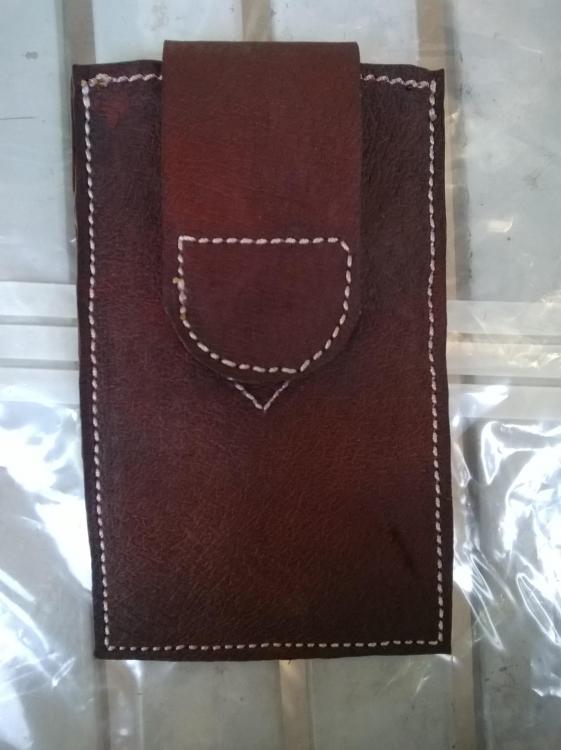

Hi, Has anyone an deep knowledge about the differences between FULL GRAIN PIG LEATHER and SPLIT COW LEATHER? Over here I started to Switch to full grain pig leather due to it being cheaper and IMHO stronger (doesnt rip at all) and it is dyed. Before I bought the expensier cow leather which they sold me for full grain but in reality I am sure it is split leather. I can rip it when applied with force. Cow leather is not dyed at all. I for my part like pig leather better since it's full grain and sometimes softer than the cow leather. But customers do not trust as much the longevity and durability of pig leather and so I ask here if someone knows some deeper knowledge about the differences. Quality, durability, stays soft - gets hard over time, etc. See here some works from pig leather versus cow leather. Second below (dark) leather item is full grain pig leather (Smartphone case). First below (light coloured) leather is an pistol Holster from split cow leather.

-

- full grain

- split

-

(and 3 more)

Tagged with:

-

I would like to skive/split and finish some entire sides of Hermann Oak leather. I'd like to get them down to 3 oz (from 8-10oz) with a good, clean looking back. Does anyone know of a place that would offer this service? (I'm aware Wicket & Craig does this in-house for their leathers, but I haven't heard the same for Hermann Oak) Thanks!

-

8" Pull Through Splitter With Spare Blade For Sale. $250 shipped to North America I have two pull through splitters and barely use this one. In fact, it's probably only split 25 pieces of leather in its lifetime. This model is a clone of an Osborne 84 and works well. It comes complete with a spare blade that has never been opened and the fitted blade was kept sharp using a simple jig and a lansky sharpening system. The current edge is very clean, polished, and free from nicks or dents. I've also attached a simple collar and pin to the depth adjustment arm to allow more accurate repeated splits. This is attached via friction and can easily be removed is so desired. The paper scale you can see has arbitrary units and is simply a reference scale when splitting multiple pieces of leather to the same thickness. Please see the the images below for more details and don't hesitate to ask any further questions you might have.

-

This fella John has asked me to make him a three quarter length coat in a few crocodile hides he's prepared (he hunts, taxidermies and tans leather of crocs and smaller animals in Australia and Papua New Guinea and gold prospects in PNG too) but they're about 4-5mm thick (10-12 ounces). I didn't get the ruler flush with the leather in my photo. To make a garment I'd need it to be at last half that or ideally a quarter of that thickness. I've never used a splitter before so I don't know how it would go with the scales of the skin side. I'm going to ask the companies Packer and Maclace in Australia and also thought you guys would have a great idea on how to do it. To do it myself, John suggested I could sand it off, he tried by hand but it's too laborous for him. A mate knows someone with a splitter with the width of 700mm so that should be sufficient so they'll get back to me. I'd cut off the limbs on the hide so it would be flat I reckon. On a side note regarding the job: To make the coat John wants the scales in the centre of the back of the coat and that's the only requirement. The rest of the garment would look better using full belly pieces which are smooth and flat but I reckon he wouldn't have any hides cut down the back so the belly isn't divided down the middle so they'll be a lot of seams in the coat. If it ends up being only split half thickness I'd have to sew the seams on top of each other, without a seam allowance.

-

Can Anybody Identify The Maker Of This Bech Splitter?

Logans Leather posted a topic in Leather Tools

Does anyone recognize this splitter? Can anyone tell e who made it? Do they make them still? Looks like it may be a one-off made in a machine shop, but made darn well! If I cannot find a maker nor any patent or licensing info on it, I may start having them reproduced. I have a great machinist here in town who can fabricate all the parts and will grind the blades, and one of the best blade makers/swordsmiths in the country is right here in town too(K.C. Lund) and he can do the heat treat on the 01 steel blades. We can even offer pattern welded (Damascus) blades if anyone wants to pay a ridiculous amount for one Let me know if y'all are interested, so I can look into whether or not it will be worthwhile to have these cranked out.- 12 replies

-

- leather splitter

- splitter

-

(and 6 more)

Tagged with:

-

I'm wondering if anyone has ideas for minimizing the split on tooled edges when rounding a curved surface (e.g. motorcycle handgrips, flasks, etc.). Whether wet carving with a swivel knife first or dry carving, I can't seem to get away from a split that seems it may grow or spread over time whenever I wrap an item with a substantial curve. Any thoughts? Thanks.