Search the Community

Showing results for tags 'timing belt'.

-

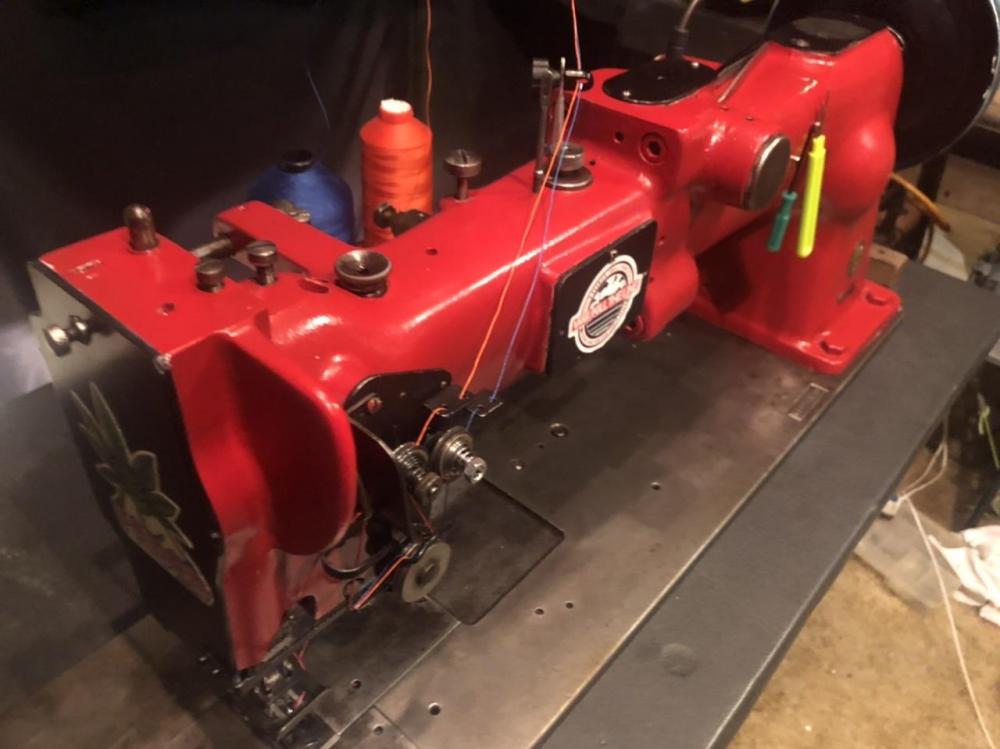

Hey, New here. Joined mainly because I've visited many times, found help with several issues and wanted to thank you guys. Uwe's video helped me time my 111W-155 after struggling for days with a new hook. I found links to things like manuals and admired your custom tables. Been sewing since I was nine, a third generation seamstress. I mostly create street rod upholstery, but I also do furniture; currently sewing up a Barcelona sofa with button tufting. I do all of my own maintenance and adjusting, occasionally buy used machines and restore them, etc. I have two decent leather machines, a 111W-155 and a National 26-188 with a large handwheel and a servo. These two sew like they were brand new. I've had the 111W-155 since 1995 and only last week put a hook in it for the first time. I have a red eye (treadle) for when they shut the power grid down, it won't sew leather, but if I rip my pants, I'm covered! I got a double needle 112-140 recently, but I can't get the handwheel off to put a timing belt on her. The heads of the set screws are gone. Seems that's why there were parts missing and no belt, LOL! I'm guessing I'll have to drill out what's left of the set screws. The repairman that used to come to the shop died of old age, nobody makes "house calls" anymore, my truck gets eight miles to a gallon, so I'm not loadin' that filthy beast up and hauling her in to be repaired. She can sit in the corner and get even rustier. So, many thanks to those of you who post suggestions and solutions, and I wanted you to know I both look up to you and look you up when I can't solve something. I also came across something cool that you might want to check out if you want wheels on your stands, look for "workbench casters" on Amazon. You can raise and lower it with these. The K stands might be tricky to put them on, but they work great on straight tables if you use through bolts and enlarge the holes enough to accommodate the bolts. It's time to work the puzzle! G'night from Jama

-

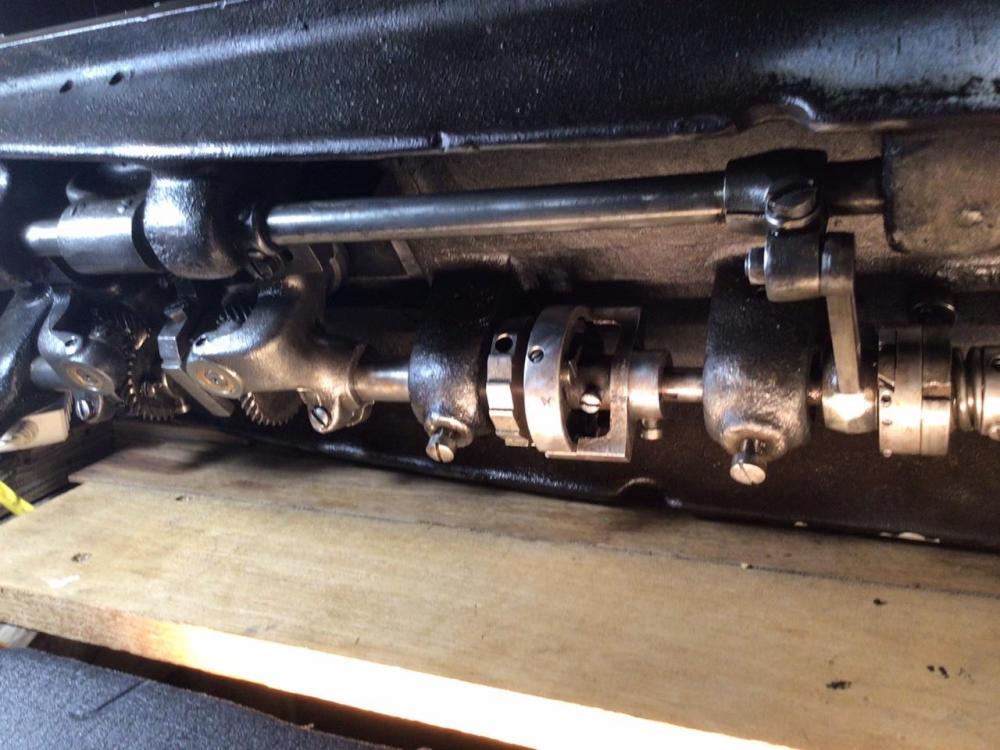

My 145w204 had been sitting since the 70’s when I purchased it a couple weeks ago. It had no rust, but was covered in decades of warehouse storage, spiders, and varnished oil. Machine wasn’t seized, but very close to it. Mainly old oil that had turned to glue. Got it tore down and polished everything clean and smooth. Stitched like a champ. Belt came in and I swapped out the old dry rotted one. Still worked, but not for long. So I put the new belt on exactly like the manual calls for, and I’ve done it 50 more times to be sure. Long story short, everything looks perfect, hooks to needle, runs smooth and quiet, my problem, the feed dogs will not keep time with the needle. At zero feed yes, they line up, start adding stitch length and forget about. Almost seems like something is 180 degrees off. I did not disassemble anything on the eccentrics, just clean and oil. I did check for loose bolts but all was good. So that’s the the gig, my feed dogs and needles won’t time, but everything else looks good. Any advice, hints, or means to a solution would be greatly appreciated. Thanks.

- 2 replies

-

- feed dogs

- timing adjustment

-

(and 2 more)

Tagged with:

-

Good Morning all, first time poster.Need help with re-timing the adler after I slipped the timing belt off the cog pulleys in order to isolate the upper shaft [needle] and lower gearing[bobbin] to unstick the old girl. It is untuck now so I need to put it back together. I am in deep! ANY HELP

-

I have the original manual and a variety of military manuals. I've read previous forum posts on here and looked for videos. I've taken out / loosened all screws involved and I removed the pully. This bushing is stuck! This machine is a beauty and has about 99% of all it's original USA parts. The bushing is original USA and I don't think it's ever been removed. The machine belonged to an elderly woman who sold her house and left the machine there for the realtor to get rid of. I got wild and chopped out the original timing belt for obvious old belt reasons. I'm trying to get the bushing out to put the new belt on. I can't help but think I must be missing something. If there are tricks to getting out arm bushings that seem fused in, I am open to any and all suggestions.

- 23 replies

-

Hello everyone. Just got my 1st walking foot machine...Consew 225. It works but it needs TLC. Planning to make it work better, do some restoration to original condition and install Consew 226R parts to allow it to reverse. Lots of questions for you: 1. I have the 10 page Operating Instructions for Consew Models 224 & 224R-1 / 225 & 226R-1 and the 3-page Parts Chart from the Consew website. Does anyone have the parts list that describes the parts with numbers? This way I know how to refer to each part. 2. Timing belt needs replacing. I have removed the handwheel but cannot figure out how to remove the drive shaft bearing. The bearing sits in a housing. How do I get the housing out of the cast-iron machine housing? 3. To remove the belt it looks like a retaining ring needs to be removed. What is the easiest way to get this off? 4. The lifter works now but it is repaired and ugly. And the hand operated lifting lever is missing. In addition, the thread is not released so some fixes are needed. Using the lifting bar for the foot pedal is fine with me. It seems that I need several parts to accomplish this. The hand lifter area is the worst area. Part of the head casting is broken in this area. I plan to make a SS cover for this area and use some available threaded holes to hold it in place. Do you have any watch-outs? Can someone send a couple of pics of what this area should look like including close-ups for the hand lifter as I can't see how that lever will be installed. 5. Finally I want to add reverse capability. The 225 is similar to the 226R-1 so I think I can fit the 226R parts into the 225. Is this possible? It looks like the rotating point of the reverse lever will fit in the hole under the handwheel. I'll send more pics. If possible can you send some pics showing the reverse mechanisms on the 226R? Many many thanks in advance

- 8 replies

-

- timing

- timing belt

- (and 3 more)