-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by SethJ

-

Heavy molding ,..I'll soak in hot water,..then oven dry on low temp. Light molding,..I'll just wet with a rag,..like extreme casing,...and let air dry to shape. I have made templates from wood that I use for cases, mag pouches and such,..wet leather,...clamp it in the templates until dry....

-

I've tried the wledwood and other contact cements,...the only one I've found that I like on saddles and holsters and such is the Leathercrafters Contact Cement,.....that or barge. The other stuff can be pulled apart fairly easily,..this stuff,...it will tear the fibers of the leather if you let it cure and try to rip it apart. Yea I didnt really get that either,..I want it STUCK! I figured he meant he wanted it held until he could sew it. I cement almost everything I sew.

-

Anybody know where I can get a stapler that will punch like up to 6oz leather,..something like what I could use to make belt keepers?

-

Oh I completely agree....but at the time I started this post,...I was almost suicidal,..lol,...thank goodness i've worked some of the issues out with the help of Bob Sr and Jr,...and a hell of a lot of trial and error. And YES I think a big part of finding a solution was help from the members in here,...many very helpful posts!!!

-

did this on the 4500 too..... Ok back on topic,...yea I thought I'd heard somewhere that maybe I have to use round point needles when sewing shearling to skirting??

-

Ok let me clarify before the nazis all come out. I'm NOT bad mouthing the " Bobs". Its just frustrating like I said. My youtube video is hardly mainstream and was for the purpose of showing the Bobs...and you guys...not to tell the world. anyhow....after A LOT of experimentation this week I have a lot of the issues worked out I think. THREAD seems to be a big issue!White 277...no probl;em,...like a dream. BLACK 346,...no problem,..just run a tad slower. The white 346,..forget it lol. I may try another brand. I was able to sew a holster welt,..most of the problem was ME holding the piece at an angle in the foot,.,,,causing some deflection of the needle,..missing bobbin pickup etc.... Dryer leather does seem to sew better,..less feet print and other "white thread / dye issues) Many of the issuses were a cummulation of a buncha little things,....I think a bunch of you guys suggestions helped a LOT so THANK YOU! And THANK YOU Bob,..and Bob....I know Bob Jr has been down with the flu,..so I been trying not to bug him,..lol Let me say this,...the 4500 runs AMAZING when you do your part. Its just a LOT of stuff to watch out for,..and i find I have to adjust tension when going from thicknesses. And a few other adjustments. I forgot what you call it,..but where the needle goes thru the lil hole in the like foot part,...mine was maligned,...and one of my presser feet was bent from a previous wreck and deflection,....so I straightened those out,..and shredding has stopped. Also whoever said to run the thread thru the tension guid twice,..like in and back out,..that helped tremendously!!!! So all in all its running pretty good,..lots of little things coming together to create a calamity of problems.....most ATTRIBUTED TO USER ERROR! DOH* Oh,.by the way I'm in Louisiana. Heres a holster I was able to get done the other day with the machine. theres some other stuff on my page I recently did with the machine too,..cellphone cases etc... feel free to look www.facebook.com/sjfineleathers and iif you want to friend me personally,....spook spook the sniper thats my facebook. I havent been on much because I had a client wanted a saddle this week and i've been bowed up working on that. DIDNT I READ SOMEWHERE about sewing shearling with the 4500? A Different needle of something? Something about the shearling getting snagged????

-

This might sound stupid,..but I have a roll of Black 346 that runs ok on the bobbin and the top......white runs like crap,..the black runs good! lol I think I'm losing my mind. The black even feels different,..like softer,..not as brittle,.....

-

Ok the flywheel issue has been resolved! The 346 thread was snagging in the bobbin race and locking everything up,...Flywheel is TIGHT! the shft was even turning. But this issue seems to have been resolved on changing the bobbin race!

-

No No! I have some 26! I'm running 26 with 346 on top this morning,.....and 277 on bobbin,....doing some experiments...just hang tight,..I do however need the holster plate which I didnt recieve? QUESTION?: Does the holster plate use the walker foot? Or is it removed like the stirrup plate?

-

ILooking back my comments seem harsh about it being a dud,.....let me catch my breath,....I'm SO FRUSTRATED. The machine runs well under ideal conditions,....it's just destroyed a LOT of my work,...and its really bugging me. When it does work,..it works beautifully......I just have to get past these issues and I'm concerned.

-

GREAT INPUT THANK YOU!

-

Thanks for all the replies! Ok this morning I'm back trying again. I have re threaded the machine and changed the needle to a #26. Oh The flywheel issue- Bob had sent a new bobbin race and since installing it,..I dont seem to have that issue anymore(YES THE FLYWHEEL WAS TIGHT) that was the first thing I thought too. But the shaft would turn,..just nothing would move. Ok I rethreaded with #346 on top with a 26 needle,..and 277 on the bobbin. I also threaded like someone said going thru the eyelet over the tensioner twice(in and out)...... I HAVE NO DOUBT ITS USER ERROR LOL....the machine runs too well when it does run,...so its something going on ... does anybody know about WET leather? It seems to affect the sewing. Ok I just put two perfectly flat pieces of 10 ounce in the machine. It sewed it perfectly for about 20 stitches then I stopped,..no issue,..stitches look good,..tension looks good,..knot is hidden,..no pucker. The issue comes when I have a good prepared piece of work!!!AAARRGGGHHH!!! Like the edge of a holster.....I THINK I AM DEFINATELY GETTING SOME NEEDLE DEFLECTION AS SOMEONE MENTIONED.....AND YES IT SHREDS ON A MISSED STITCH only,..NO OTHER TIME...... getting closer!! I think the WET leather is a big issue,.....something happening there....

-

I'm uploading a video of the thread breaking and fraying. I've adjusted tension great,..and less,..and everywhere in between with no sucess. I should say,..with the 277 thread.//I HAVE been able to sew up to 10 ounce thick. Whether its two thin pieces,..or a single ply of 8-10 ounce,....the problems really appear when going to thicker materials..... ah after a search,..you guys call it thread shredding,....thats what my machine does on anything over 10 ounce. I have 277 thread with a 25 needle,...it does fine on thinner leather thats untreated in any way( not dyed or cased). HAS to be something out of adjustment,...I just stitched a single ply good heavy 10 oz,..and it performed flawlessly,..why cant I sew thicker?!?!?!?!!? I have to sew welts and such that are nearly 1/2" thick! http://www.youtube.com/watch?v=eLj_06dZlzk&feature=youtu.be

-

Something else,..I just tried again,..adjusted tension for a heavy welt I was trying to sew. The thread will BREAK after a few stitches,..its like it gets hung somewhere and it gets cut at the needle and frayed,...when going into the leather,...it rubs the side of the little guide hole.....I posted a video here,.....this is the jamming problem,... http://www.youtube.com/watch?v=DyknrGtA_JQ&feature=youtu.be

-

Well, after debating between the cobra and the cowboy,..I guess I really screwed up. I went with the Cowboy from toledo and Bob. Nothing but trouble since I got it. To start some parts were missing. Waited and got those in. But the machine simply WILL NOT PERFORM. It ran ok for the first oh,..30 minutes,..then that was it. Nothing but problems. I've damaged so much product I'm sick to my stomach. The service is ok I suppose,...I keep speaking with Bob Jr. ...but anyhow,..he's sent me several parts,..trying this and that ,..and nothing's working. I can sew a single thickness of oh say 10 ounce,..DRY! not dyed,..or even slightly damp is a problem. When trying to sew,..it will make 3 or 4 stitches,...the the thread gets frayed and mangled on the needle. It randomly skips stitches,....it makes a grinding noise when the needle goes into the leather. Sometimes,...the machine locks up! I mean something gets stuck,..and the belt turns,...but nothing moves,..its a bobbin problem supposedly,.....(we changed the bobbin race already).... I switched from 346 thread,..to 277....that helped some,...now I can make oh 10 stitches before it malfunctions,..... Does it matter if the leather is damp? Seems like it really goes to hell when I try and sew even slightly damp leather. I'm still talking to Bob Jr,..but it doesn't seem to be getting anywhere,.....its been 3 weeks,..and I cannot complete a single project. I'm completely frustrated and pretty disgusted after spending $3000....it looks like a TOTAL Waste of money. Are these machines supposed to be this troublesome???????? I'm at my absolute wits end and I'm fixing to take drastic measures.....any advice???

-

Nevermind,..I just called Bob and ordered a cb4500.

- 27 replies

-

- sewing

- sewing machine

-

(and 2 more)

Tagged with:

-

Ok I have another question, would the 3200 be ok for saddle work? Is the extra arm length absolutely needed?

- 27 replies

-

- sewing

- sewing machine

-

(and 2 more)

Tagged with:

-

Ok, so I did talk to Steve yesterday and he answered all of my questions concerning the cobra class 4 machine ,...but I forgot to ask him this one...Why won't the machine sew anything lighter than 6oz? So am I to understand it will sew together 2 thicknesses of 3oz totaling 6oZ? I don't exactly understand why the machine wouldn't handle lighter leathers?

-

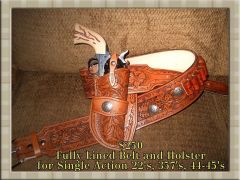

From the album: Some stuff

Mexican 2 Loop -

From the album: Some stuff

Carved rig for an EAA Bounty Hunter