Whit30

-

Posts

79 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Whit30

-

-

Hello,

I am wanting to make a wood sided bag using some oil tanned leather I have around.

My question is on construction. I would probably use Walnut for the sides. On something small as a phone case, somewhat bigger as a fire kit pouch would 1/4" be strong enough?

And for larger bags such as a laptop or I pad bag maybe even a purse, do you feel 1/2" thick walnut would be structural strong enough.

I am planning on drilling holes in the sides and sewing the leather to the wood. I have #69 nylon thread. Should this be ok? How far would you space the stiches?

Lastly for now, would you skive the leather that I will cement to the wood edge or leave it the same thickness? Would it be better to sew something like every other hole around entire side and come back with a second thread sewn separately incase a thread is frayed or cut some way and the whole thing wouldnt loosen up or just cross stitch the sides with one thread? Would you cement over the thread to protect it from wear?

I'm sorry, I know a lot of questions but I just like to have everything planned out and squared away before starting something new

Thank you for any and all tops and advice!

-

Beautiful work! Do you mind explaining the process of securing the blade to the bearing? I understand that the bearing can be installed on the tight side for a pressure fit into the Harrell, but do you also press the blade into ihe bearing and it is held by pressure fit as well so 've there is no set screw? And do you mind sharing where you sourced your bearings? Any tips or advice would be greatly appreciated!

Thank you!

-

Looks great! When attaching the sides and forming the creases, did you gouge the inside and still fold toward the outside? Thanks!

-

Thank you Plinker! I appreciate it!!

-

Thank you for your time and answer!

-

Hello everyone, I am not having any luck finding paterns for a Buck 110 and 112. Can anyone help me with locating these? I really am wanting the automatic opening sheath but if I can locate a good standard sheath as well that would be great. Thanks so much in advance!

-

This is sold. Thank you!

-

This is still for sale, Thanks

-

Thank you but this is no longer needed.

-

Thank you for the reply! I'm actually wondering what the older Cast Iron one's are selling for now. Thanks!

-

Hello all, what is the going price for a Tippman Cast Iron these days with a flat bed attachment? Thank you

-

Price has been lowered to 400.00 including domestic shipping. Thank you

-

-

Thanks for the reply and info! I appreciate it!

-

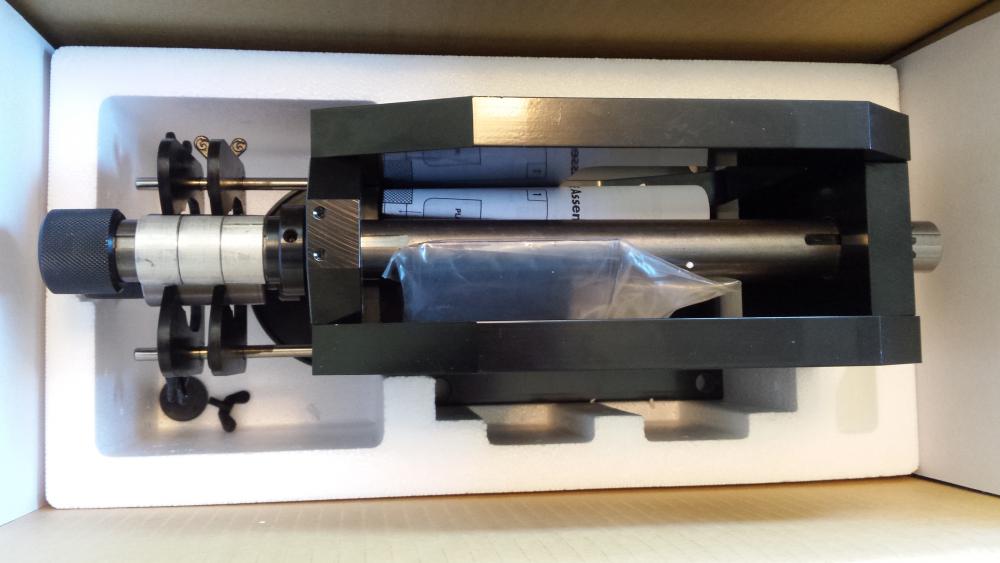

Hello everyone,

Could use some advice before listing a Pro Embosser that has never been taken out of the box. I bought this several years ago and due to health issues, never used it. I think it's time for a new home but having trouble finding a new one and I don't remember what I paid for it so I could sure use a fair value for this. No wheels, just the machine. Any help would be greatly appreciated

-

Could anyone direct me to a pattern for a Bond arms texas defender? I would be very greatful. Thank you!

-

I've been thinking of selling the two I have. The Leather secrets and design artistry. Do you guys feel 400.00 for both would be a fair price for both buyer and seller? Thank you

-

Incredable holster and finish! Thanks so much for sharing how you achieved it. I have a question on th dip dye. will it last longer and give a better shine and look? and is there a down side? will it crack eaiser, flake off or not last as long as standard hand dye?

Last question, I would love to make a holster and belt that looks just like the holster Colt Hammerless made same color and all. Will the constant wear for a concealed carry belt/holster dyed this way last as good as other type of finishes or not too long. Thank you for all of the advice and ideas in advance!

-

Thank you so much for the help and links. I truly appreciate it! Take care and thanks again!

-

-

Could sure use some help from all of the tool experts. I picked several of these up and there are no makers mark and they were pretty dirty and gunked up so they havent been used in years would be my guess. The first one and the smallest of the three has a ruber handle material. The second is all metal and a knurled handle. The third one is the only one that has a removeable blade like what is used today but the blade is threaded rather than being held in by a setscrew.

the tips of these are not all ground the same so i;m guessing the owner/maker used them for differant cuts. Most of the smaller rubber handled knived have a grind that looks similair to a small v shape. The larger ones have an even grind but is thicker than a normal blade would be so I would think it would be a thicker cut. The only ones that have a sharp blade are the last ones with the threaded removeable blade.

with all of that being said, I am thinking of putting a sharp grind/tip and use them as any other knife I have. Is this what any of you recomend? I have eight each of the first two and two with the removeable blades.

Thanks for the help!

-

Hello, Can any of you tell me if the two Leather Secrets books by Baird are still desired and what would be a fair price to list them for. I was thinking of putting his third smaller book it with the set as well. The Leather Secrets are in verry good condition.

Thanks for the advice!

-

If anyone can help direct me to a pattern or would be willing to share one for a speedloader case I would be very greatful. I found a drawing somewhere on this dite but couldn't figure it out. Thanks a million for your time

-

Hello, First of all I want to thank everyone for the continued help you offer. I only ask that if you reply to this thread please dont treat it like a stupid question. This is what I have. My Mother in Law found at a garage sale a bunch of leather tools many being USA Craftools. These are nolonger shinny chrome and beside the dull look some oxidation. What should I use and how to revive these tools to put them in the workforce without messing them up or stripping or softening the chrome on them.

I saw on the commercial for a cleaner CLR that said its safe for chrome. would you recomend this as a soak or find chrome cleaner for cars and clean them one by one?

Thank you for your help, I really appreciate the advice, I sure don't want to mess these up.

Please advise for wood sided leather bag

in How Do I Do That?

Posted

I'm sorry, I somehow double clicked and i double posted this question. Can someone help me delete the second one? I'm sorry. Thank you!