-

Content Count

653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Blogs

Gallery

Store

Everything posted by Eaglestroker

-

Innovative Knife Sheaths

Eaglestroker replied to malabar's topic in Gun Holsters, Rifle Slings and Knife Sheathes

malabar, you jogged my memory so here is the most unique sheath I've made, and I know I have not seen another one of these. I work with a local knife maker who is also a good customer and he was introducing a line of CNC neck knives and sent me a couple for myself and a few friends to test. I found using his kydex sheath and a tek-lok that it was a pretty natural addition to the front of the waste line and started wondering how I could incorporate it into being a 'last ditch effort' sort of back up knife. Thus, the in belt sheath. I can make it work for a 1.5" belt but it is better with a 1.75". There is a welt in there but I'm currently experimenting with a kydex liner just because. This is a fairly rough prototype pictured but you get the idea. -

Innovative Knife Sheaths

Eaglestroker replied to malabar's topic in Gun Holsters, Rifle Slings and Knife Sheathes

My favorite sheath I've made was a high riding number for a short fat blade. It is probably a style easier to hand than machine stitch but I did it by machine anyway. I made this about 3 years ago. Liked the combo so much that I ordered a knife for myself and in all my free time would like to make a variant that sits between the belt and the pants. Not a fan of how the majority of sheaths have so much handle coverage it is a pain to draw them so that plays a part in all of my sheath designs. -

Gluing Edges Instead Of Stitching

Eaglestroker replied to seabee's topic in Gun Holsters, Rifle Slings and Knife Sheathes

The problem you will run into with this, long term, is that after a lot of draws the liner will start to seperate and the gun will snag it when holstering. Every time it snags the seperation will continue, so your nice lined holster will be unserviceable. If their is a lining it needs to be stiched to prevent that from happening which is not an *if* but a when. -

Curved Slots

Eaglestroker replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

There is a perception that they have a better bite, and whether or not that is a reality customer perception is a perfectly legitimate answer. Red Nichols has used a curved slot that only punches out the upper and lower circle, leaving the center cut on one side with the material left to 'bite' the belt and keep it from moving. I've seen Josh Bossart use and talk about this method as well. I tried having a punch made for a curved slot for tight pattern pancakes that would allow me nicer curves versus the straight lines for/aft in the 'wings' of the pancake. Curves can help keep the clothes from sticking, and frankly they look nicer to my eye. For my purposes I decided against having the curved one in my line up as the confidence wasn't there for it being done right after the first attempt. I have straight punches for 1.5" & 1.75" that cover most anything I ever need to do, and outside of the Cobra were the biggest time savers in my shop. -

1911 Under Shark

Eaglestroker replied to Eaglestroker's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Red, the holes in the hanger are roughly half inch, I space belt holes at 3/4" for more adjustment. Some folks do it at 1", just personal preference. The plastic starts about 6" from the buckle fold and ends roughly 1" from the first hole. -

1911 Under Shark

Eaglestroker replied to Eaglestroker's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looking at your work, and your time joined on the forum, no doubts that you'll surpass me if you stay at it. Leather isn't science most of the time just a lot of experience! I'm sure there are a lot of different terminologies for the strap, like so: http://www.amazon.com/Oatey-33925-Plastic-Bagged-25-Feet/dp/B000MIUCG2/ref=sr_1_sc_1?ie=UTF8&qid=1437743934&sr=8-1-spell&keywords=plastic+pipe+hangar -

1911 Under Shark

Eaglestroker replied to Eaglestroker's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you sir. Thanks Red! Sorry for chuckling at your expense Jason! Hey LT, some folks use banding of the metal or plastic variety. I line them with pipe hanger getting good results. Brace is just a fancy way of saying pair. -

-

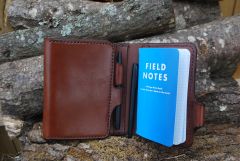

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

From the album: Just a taste.

-

10934137 1578460992400037 22732769976930683 O

Eaglestroker posted a gallery image in Our Leatherwork Galleries

From the album: Just a taste.

-

10941115 1576411052605031 4730060683961788209 N

Eaglestroker posted a gallery image in Our Leatherwork Galleries

From the album: Just a taste.