bigsig11010

-

Content Count

81 -

Joined

-

Last visited

Posts posted by bigsig11010

-

-

-

Yes sorry

-

Got my cowboy outlaw from mr Bob at Toledo this week. It come with the standard double toe foot and also single left and right. When do you use the single toe feet? What projects or circumstances would dictate changing to a single toe?

-

Can anyone provide info on this machine and if it will be a good machine for med leather.

-

I’ve noticed that on some projects the seams and stitches are on the outside like box stitched while others are stitched then the work is turned inside out so that the seam and stitches are hidden. Are there rules for when to use which or is it just what the maker likes or wants on a project?

thank you

chris

-

I have a Seiko stw 8/consew 225. My first industrial type machine. I have some experience with lighter weight machines and I know there is a step to disengage the sewing mechanism while loading the bobbin with thread. I don’t see anything like that on the industrial machine. Am I missing something or does it just carry on even with nothing being sewn while loading a bobbin? Won’t that create tangles or other issues. Like dry firing a weapon or something?

-

Interesting how you did your seams. Is that a specific kind of stitching? Or did it just happen that way. I’m very new and trying to learn. I’ve done one multi tool pouch but I’d be ashamed to post a pic of it lol. I think yours looks great. I was trying to learn to use a machine and trying to set up and adjust the machine all at the same time and obviously the seam ripper is not your friend when working with leather.

-

Great info. Thanks.

-

I have a Seiko stw 8/consew 225. I’ve seen videos of machines using a roller foot. Could I put a roller foot on my machine and I guess more importantly why would I want or need to?

-

Ok thank you

-

Thank you.

-

-

What is the range of needle and thread sizes on the cb outlaw? I know the info says comes with a spool of 277 thread but I don’t see the range options.

-

What type motor does it have?

-

-

Just when I thought things were getting better I had a run of terrible stitches. I noticed that the thread had come off the bottom guide and the slack had allowed it to loop up above. I re threaded and did ok for a couple of runs then it happened again.

When the lever comes down the thread gets really slack and the slack is letting it come off the lower disc. Im posting a couple of pics. Is the thread supposed to go behind the little notch in the opening on the lower disc? Or is the spring supposed to control this. Not sure what Im doing wrong.

-

-

Which size needle with the 92 thread?

-

I stuck with thread cause machine guy said the timing issue was causing pinching the thread and that was causing thread issue but I’ll try something different and see. I know uwe has a thread with a 225 using 207 top and bottom and looking great. I was trying to adjust one thing at a time since it seems that every change triggers a domino effect of other things. Also I was trying to use different color top from bottom so I could tell which side wasn’t acting right.

I’ll try 92 top and bottom and different needle and see

-

-

I’ve tried 2 different Tandy stores and neither had a cowboy outlaw machine that I could look at. One had a boss but the demo was broken. I just can’t get comfy spending 1400 for something I can’t see in person. I bought a used Seiko stw 8/ consew 225 and after a month of tinkering and one trip to the shop I’m still not able to sew on the thing. I’m very frustrated. I have a couple of threads on here about my efforts. I think I’d buy an outlaw if I could try it out.

-

I want to buy a used cowboy outlaw sewing machine.

-

Is this still available?

-

I’ve watched Uwe’s video on the hook timing on consew 225. I’m wondering if I should try to do this myself or take it to a sewing machine person and have them do it so I don’t make things worse? Is it something that if I try and don’t get it right then have to take it to someone then they are going to say I should have left it alone.

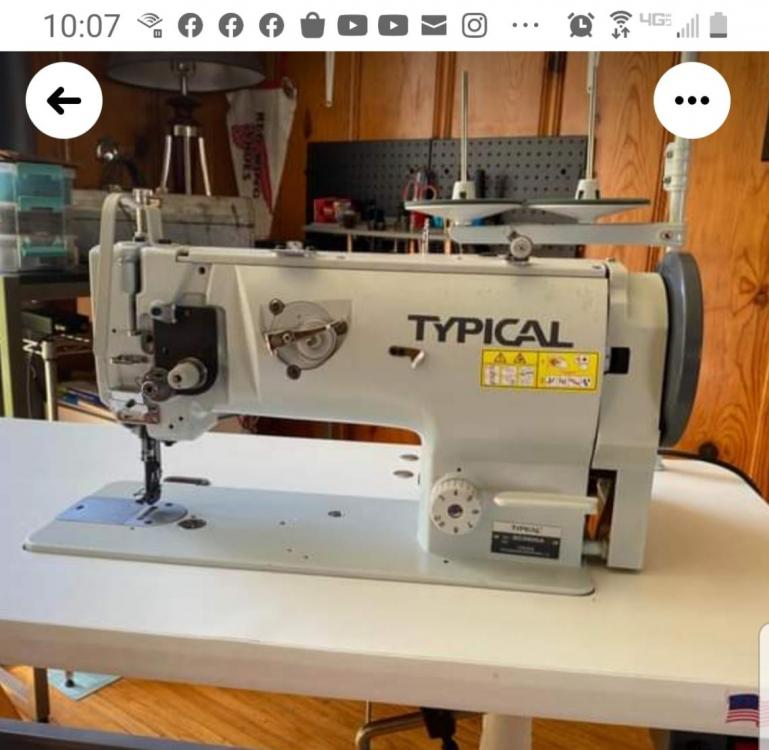

Typical GC050A

in Leather Sewing Machines

Posted · Report reply

Is it considered a 441 clone?