-

Content Count

5,306 -

Joined

-

Last visited

Posts posted by Constabulary

-

-

You are welcome

BTW - toothed V-belts are better when you go around small size pulleys.

BTW - toothed V-belts are better when you go around small size pulleys.

-

Back then I had no proper size V belt for the test setup. But yes, it actually works.

-

-

Not sure what he used but cheap pillow blocks for 15mm shafts can be found on Ebay F.I.

Pillow Block Type KP002

https://www.ebay.com/itm/144782907792

a 40mm and 120mm pulley (for 1:3 reduction) with 15mm bore can be found here:

https://www.ebay.com/itm/264553616997

15mm shaft:

https://www.ebay.com/itm/163869249505?var=463451784748

Just some suggestions

I have used these bits for some speed reducers and I´m running one with the above components on my Singer 51w post bed machine. I just have the reducer in a different position. Depends on your stand where you mount it. This is just how I did it.

EDIT:

You may find the bits cheaper if you dig deeper but smallest pulley here is 45mm

https://www.ebay.com/itm/272680918308

-

If it was my machine I would replace the entire clutch. I think that will prevent you from headaches. The safety clutch AFAIK is the same as on the Singer 111 machines and they are still made today:

-

On 7/10/2023 at 9:10 AM, Constabulary said:Looks like the 650W motors are gone already but here is one for less that 80€ (if they do not change the price).

https://www.ebay.de/itm/285271068358

Not too bad I think.

-

Please post pictures of your machine. Assuming you have the 2nd (later) model of the Singer 51w.

This may be helpful for you:

I once converted the needle bar at an early 51w model. May be interesting for you as well - or maybe not

-

-

@Landersohn I would check the Singer Class 7 Manuals cause the upper head section looks very similar. Hope that helps.

-

I once owned a 105MO but that was quite some years ago. MO means it was meant for sewing Moccasins. IIRC it has an independent top and bottom feed and IIRC (again) it was tricky to match up top and bottom feed.

EDIT:

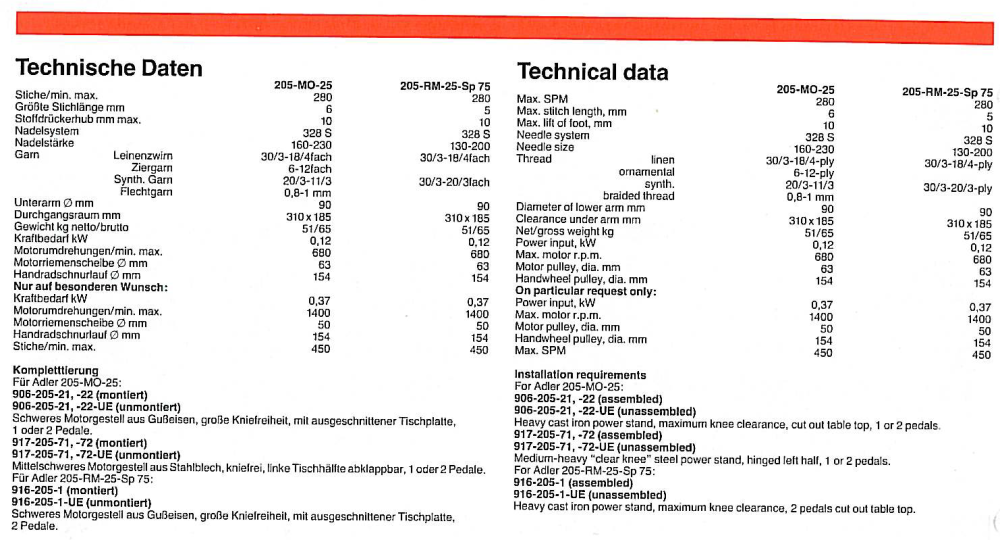

Some technical data form a leaflet but the complete file is too big to upload here. Send me your email address by a PM so I can send some more files.

-

There for sure there is a way. You have to change out certain parts (compare the parts lists of the H3 & H4) BUT I´m not sure if all the parts are still available and Pfaff OEM parts are super expensive. But most likely it will not be worth the money / trouble (my opinion). Maybe it is just the foot lifting lever and two or three other bits but I do not know for sure. You have to compare the parts lists.

-

Basically ALL 145 can sew leather it just depends on what leather thickness you want to sew and with what thread size. Keep in mind, the tag on the machine just says in what setup the machine once left the factory. It is well possible that it was been technically modified (up or downgraded for certain applications...) over the years maybe once, twice...

-

29K´s are not all the same - they may look quite similar but there are several technical differences. Which 29K do you have - the number after the K is quite important.

F.I. - I have restored a 29K1:

and a 29K71

-

you can try parts of a Seiko TF-6. They are "clones" of the Singer 18 but I´m not sure if the race is the same on wheel feed machines.

-

Kwokhing / KH Sew is a top quality manufacturer from HongKong (China). Not sure who offers their products in the US but you can buy either directly from them or f.i. College Sewing in the UK sell their products too. Sometimes you even find them on Ebay. The parts are usually marked with their distinctive KH logo. But their presser feet are more expensive that the no name feet from Ebay / Amazon but less expensive than Pfaff OEM.

-

-

Found one in my part bins that works.

Not sure what the Singer part number is but this one with # 52394 on Ebay looks quite close (just in case some one is looking for one):

-

-

On 6/22/2023 at 5:40 PM, Handstitched said:why do you keep finding these barn finds ??? not fair

Most folks don´t care about "barn find condition machines" over here and especially not old odd Singers. But that is just what I like. For sure a little bit of a challenge but when I fail it did not cots much - just some bucks for gas and oil and WD40...

Today I pulled out (no I hammered it out) the Zig Zag unit. Damn - totally seized up in the casting and WD40 and applying heat did not help much. The ZZ unit housing is aluminum and after siting in cast iron machine for several decades and the machine was sitting in a barn for... I don´t know how long... well that was a quite challenge but seems I did not damage the parts (will figure when it is back in the machine and ZZ is adjusted). The ZZ unit housing needed some good sanding and polishing but it now goes back in fairly easy but it is still tight fitting. I really feared braking it. I just needed quite some force (IMO) to drive it out - that reminded me of my 1st 111G156 when I hammered out the bushing on the hand wheel when I replaced the timing belt....

When I got it sewing and ZZ is working properly I will decide how I will go on with this machine...

-

Last thing I need is another zig zag machine

but I was looking for a 207D for quite a while cause it is a quite interesting machine. But I wanted one in a better shape and not a barn find again. Will this ever end?

but I was looking for a 207D for quite a while cause it is a quite interesting machine. But I wanted one in a better shape and not a barn find again. Will this ever end?  Well - when it is for free you just grab it, right? Maybe there must be something addictive in the Singer cast iron

Well - when it is for free you just grab it, right? Maybe there must be something addictive in the Singer cast iron

The Singer "D" machines were made in Wittenberge, Prussia and I don´t think the 207 model was made anywhere else in the world. It is a beefed up version of the Singer 206 (kind of) but the 207 has a CB hook and no timing belt but seems to have some similarities in the ZZ mechanism.

Interesting part here is that it is a CB hook zig zag machine and this (the CB hook zig zag) is AFAIK quite rare among industrial size machines, isn't it? And on top of that for a drop feed machine it has a very very long stitch length (dial say 8mm) especially for a machine of this age (WWII wartime made I guess). Stitch length dial and reverse lever seem to be from the Singer 96. So I think it is worth tinkering a little bit. Not sure where I will end with this...

The wooden table base is worm eaten so not worth saving but the plate is still quite good so maybe I´ll keep it. The wooden pedal is cool too but has a lot of surface wear.

Machine is bone dry and not spinning at all... Some picture:

-

So what machine are you using an Adler 30-7 or a Singer 29 clone / copy???

When using a Singer 29 / 29K clone / copy are you using the correct needle system 332 / 29x4 / 29x3 / or 135x16 / 135x17 and the long grove is facing left?

If you are using a 30-7 the needle is longer than for the 29 / 29K and the system is called 332 LONG / 332L.

Or try a new needle and read the manual again - this sometimes helps.

-

I do not know your machine in particular but I have changed needle bars on machines for using a different needle system. Needle bar length and diameter matter. 6.35mm / 1/4" is a Singer standard and I think the needle bar of a Singer 111w could probably work.

https://www.ebay.com/itm/152426180931

You can use needles with 2mm needle shank then. If this NB is too long just cut it down.

Since you are in the UK I would also check with College Sewing or Trojan Sewing - they for sure have this needle bar too.

-

18 minutes ago, Keevin said:Thread getting tangled up in bobbin

So what problem are you tying to explain?

Have you read the manual?

Do you have some pictures of your threaded machine?

-

I´m using this image resizer by Brice Lambson since... forever:

https://www.bricelam.net/ImageResizer/

super fast, super easy just by using the context menu (right click on picture....) in Windows

.thumb.jpg.7ff51d71924b7ec6195ad231408633d1.jpg)

.thumb.jpg.dba7ed90ffe2c1f74c61c998e3457637.jpg)

.thumb.jpg.c965c8e3b13f91cfd257037da0b49e74.jpg)

Missing parts? tension release bracket Consew 255

in Leather Sewing Machines

Posted · Report reply

This video by LW member UWE may be helpful for you: