-

Posts

89 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by KurseD

-

Arlington Machine Works industrial machines-Info?

KurseD replied to KurseD's topic in Leather Sewing Machines

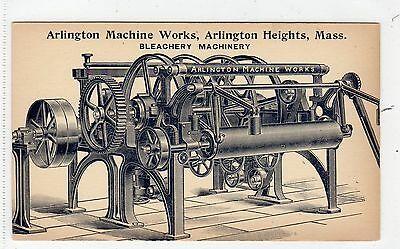

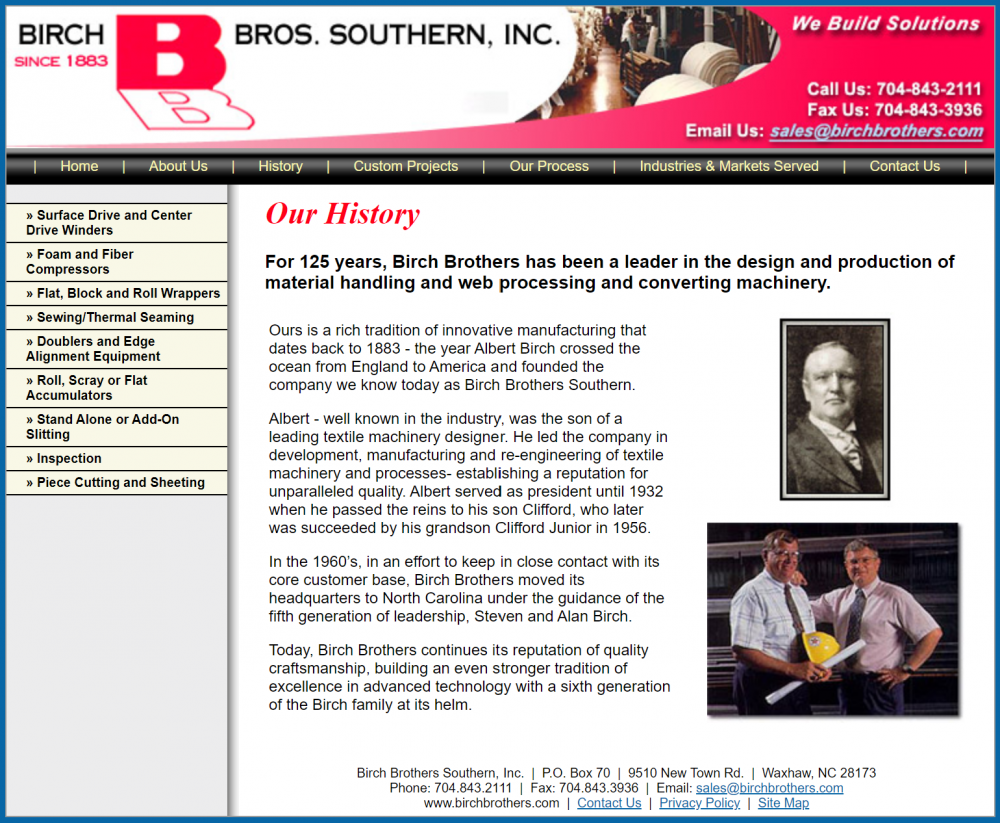

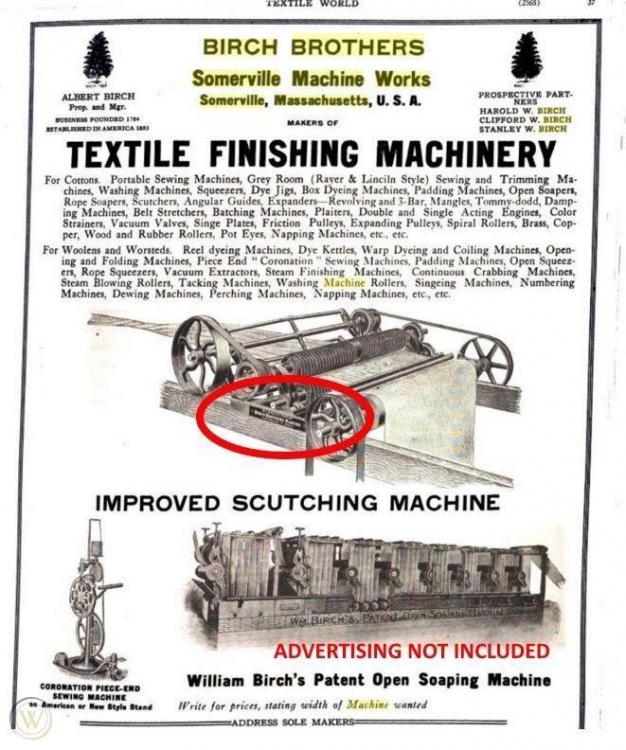

So I've been doing a bit more research, still very limited to what I am able to find. I have turned up a little info though. Apparently the Birch Bros. started their textile machinery business in Mass circa late 1880's, and at some point Arthur branched off to start "Arlington Machine Works" which was eventually re-integrated into "Birch Brothers Southern Inc." in NC circa 1960 which is still in business making machines today. -

Several of these old "Arlington Machine Works" industrial sewing machines have recently popped up in an online estate sale in my local area. I'm contemplating trying to purchase one, but I can't seem to find ANY information on them online. I'm assuming the Arlington Machine Works company is long defunct, but usually I can at least find a little info online for antique tool manufacturers. These are proving a little more elusive than most. Anyone have any experience or information with these machines?

-

Last fall my friend Jeremy Cupp that runs LC Fabrications out of Grottoes VA built me a solo seat kit for a Softail. I've been holding onto it and riding on the bare steel pan for long enough. Decided it was finally time to cover this thing. So I started with some foam that was used as a floor mat under a treadmill donated to the cause by another friend. They dye is Fiebing's pro walnut, and I used latex as a mask. Topped it all off with some Tan Kote. Not perfect, but I'm extremely happy with the outcome. 20170707_161203 20170707_175323 20170707_192227 20170707_232556 20170711_133711 20170711_173511 20170711_215715 20170712_131255 20170712_131302 20170712_131452 20170712_131459 20170712_131505 20170712_131511

-

Oak Leaf Axe Sheath

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you all so much for the awesome compliments. -

First Axe Mask completed

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yes, sorry guys for the late response and any confusion I may have caused with the wording. I said "ate", but simply meany my dye has not set quite enough or been buffed really well. I tend to over speed that step somewhat frequently. Glad you had some folks to help clarify. Thank you guys for stepping in and correcting my wording. -

Oak Leaf Axe Sheath

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you guys. -

Oak Leaf Axe Sheath

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you for all the compliments. It will get delivered this week. Hope he likes it as much as everyone else. -

Oak Leaf Axe Sheath

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks. -

Oak Leaf Axe Sheath

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

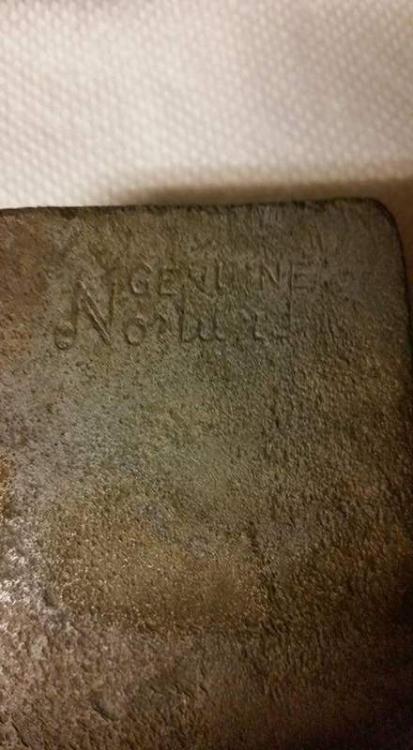

Just finished up the guy for a Norlund camp axe that I restored and I'm gifting it all to a close friend that needs a good pack axe. First attempt at tooling an oak leaf design. Fiebings pro dye in mahogany with a little dark brown hand brushed into the background, then antiqued and coated with Fiebings leather sheen. Hand stitched with Tiger thread. Hope you enjoy.

-

Dig it a lot man. The depth looks amazing.

- 15 replies

-

- leather portfolio

- leather notepad

-

(and 1 more)

Tagged with:

-

First Axe Mask completed

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you guys for the compliments. I will definitely try the Mop and glow thing. Sounds neat. I picked up a small bottle of Fiebings sheen to try as well. I have had horrible luck with Resolene so far. -

First Axe Mask completed

KurseD replied to KurseD's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks man. I cut the welt before fitting everything together, I did sand the edges light on my belt sander, but the welt was still too shallow. I think a solution to that will be cutting the welt oversize in the future and trimming it to fit after stitching. I plan on making many many more of these guys. I have two more in this batch, then I will make one for a double bit cruiser axe I am gifting to a close friend. -

Everything with this one was new. Huge learning experience, cant wait to finish the others. Simple design, but I love how it came out and the customer is very happy as well. My biggest complaint was my stitching. First time hand stitching, so I think it came out decent for such a rookie, but I think it needs to be way better. Used Tandy waxed linen thread, can't stand the stuff. Snaps too easily while stitching. Using their blunt end needles also, not a big fan there either. I ordered some 1mm Tiger thread and some John James 002 needles on recommendation from a friend. Anxious for those to arrive. Another problem I had was with the dye. So I cut Fiebings Russet color 50/50 with denatured alcohol and sprayed it through an auto detail gun. Then I used a bit of the same uncut to airbrush the edges, going for an aged look. When all was done and dried for at least 24 hours, I tried coating with Resolene, which started to eat my dye off as you can see in one of the pictures with the streaks on the backside luckily. Ended up using some Eco-Flo Super Sheen instead and it worked great. My edging needs work, stitching needs work, he'll all my skills could use a lot more practice, but isn't that always true? I'm happy with the direction I'm headed. Anyone else spot anything I haven't mentioned, feel free to critique. Hope you enjoy.

-

Well folks, been out of leatherworker and most every other hobby and craft for a few years. Family first. Long involved court battle to gain guardianship of my grandmother who is in a nursing home with dementia, father moved home from FL with tons of heart problems and passed in July, trying to maintain our home with 3 children and several pets plus renovate my father's home we inherited. Wife is working/living 3 hours from home Tue-Fri, I'm holding down full time job as a computer repair Monkey Sat-Sunday. And as if that all wasn't enough, I decided to take my hobbies and crafts to the next level by starting my own business called "Appalachian Handcraft". Needless to say it's been quite a wild ride for the past few years. But I finally picked up a few leather jobs. For now while I am still building skill and refining my style, I'm keeping cost to the customer low while trying to cover minimal supplies and tooling. Making what tools I can't afford to buy. Knocking out a few axe masks, a multi-tool sheath with flashlight sheath combo, a knife sheath, and just finished my first stitching pony. Definitely a HUGE learning curve to all these things. Making my own templates and patterns. Making due with the small tool set I have and lacking skill. I'm loving it though. Feels great to be creating again. If you're interested in checking out the business, find it on Facebook or Instagram by searching Appalachian Handcraft and clicking the thumbs up or follow buttons. Follow along with my triumphs and disasters. Also started a website. Gallery is up, but still building a good portfolio and nothing in the store section yet. Basically it's an all-inclusive handcrafted art thing, my main focus will be old time skills like leather craft, wood craft, and eventually forging some steel. I will also refurbish tools and antiques, heirloom type things. Even the kids are getting in on the action. Hope you guys dig it. Scott appalachianhandcraft.com

-

I know it won't be 100% exact, but if I can find them that will be one step closer. Thanks for the tips, off to the great Google I go a hunting.

-

I'm in the process of refurbishing my grandfather's old knife. The original sheath is beyond hope, so I want to make a replica. It has pins that push through with fold over tabs or ears on the backside.

-

Sprayed my dye, rubbed the resolene on. Rubbed two coats on, about an hour between coats. Handled water fine, but I also topped it off with neatsfoot oil after it was all done.

-

-

Thanks for the compliments.

-

My first paying leather job. My friend Jeff Hammel is building an xs650 chop and this will be rivetted to the seat pan which sits flat on the frame rails. Used Feibing's medium brown dye, 2 coats of resolene, Feibing's antiquing gell, and a couple coats of neatsfoot oil. Got two new Barry King bevelers in 0 and 2. Love them so far. Also used gum tragacanth and Feibing's tan edge coat on the edges. Will post pics on the bike when he gets the seat and sends me some.

-

I dig it man. Looks pretty slick from where I'm sitting.

-

Lookin' good.

-

Middle Street Garage (Finland) Build

KurseD replied to chancey77's topic in Motorcycles and Biker Gear

Punch would have been my second guess.