-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by enginecoleather

-

LOOKING FOR SOME HELP! I have been asked to create a leather fire bucket as a gift. I would like to keep it close to how it would have originally been constructed and i think i have a good idea of how i would like to do it. Any thoughts and ideas are greatly appreciated! I am most curious about what type of waterproofing / hardening mixture can be made/ bought that was used in the production of these buckets. I am doing as much research as possible and hope to get some ideas from you guys. Thanks, Kael

- 3 replies

-

- bucket

- fire department

-

(and 4 more)

Tagged with:

-

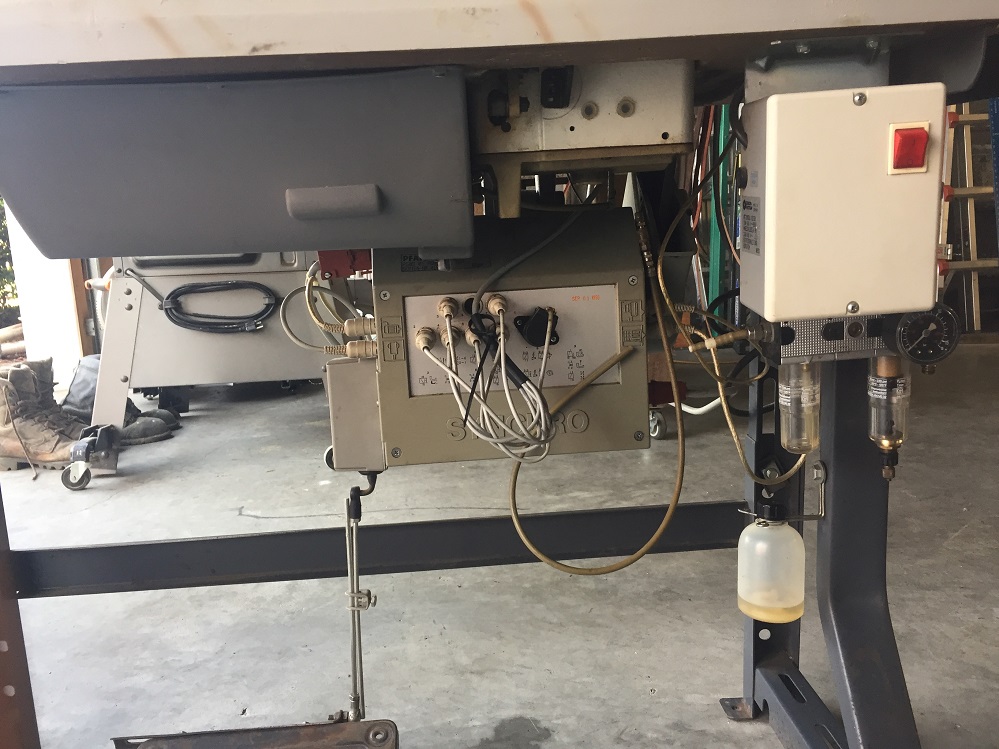

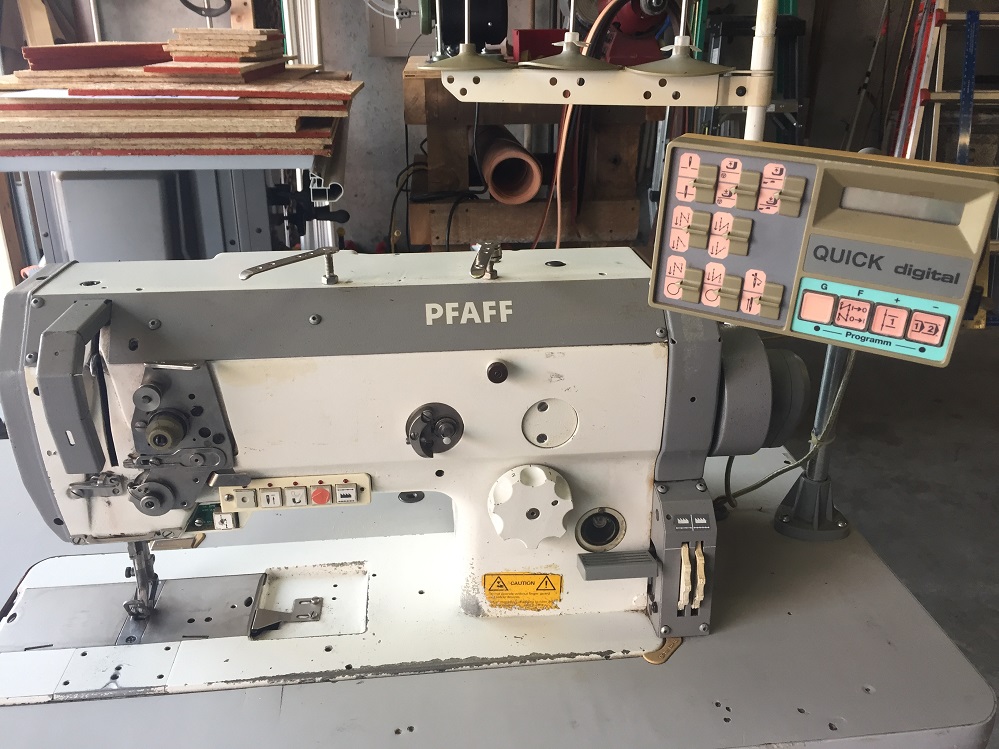

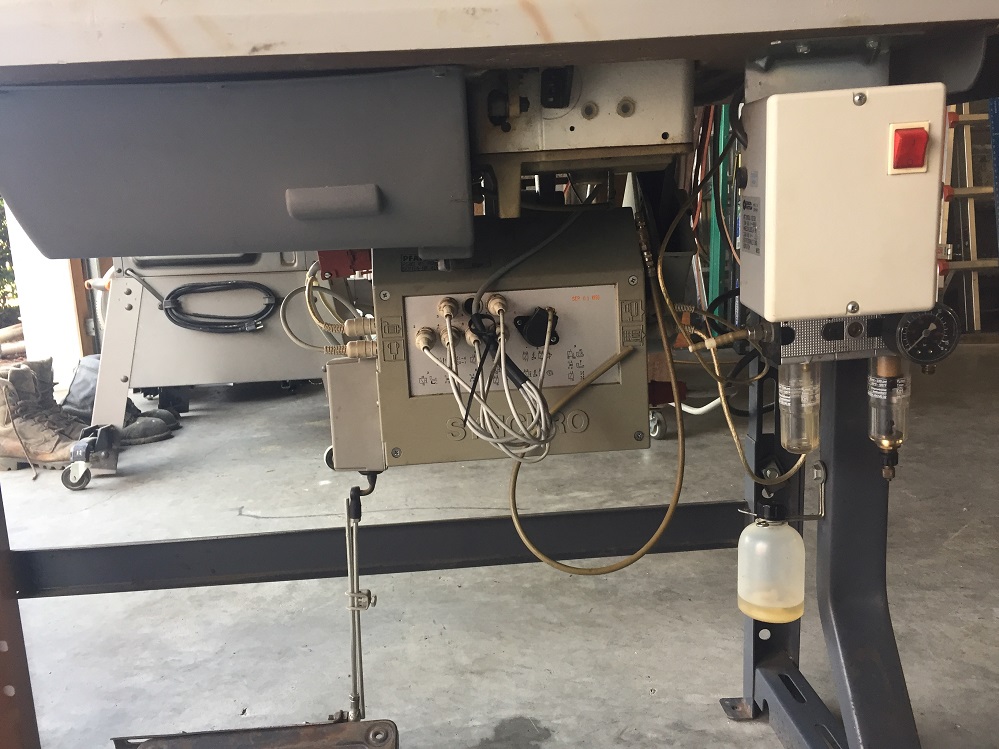

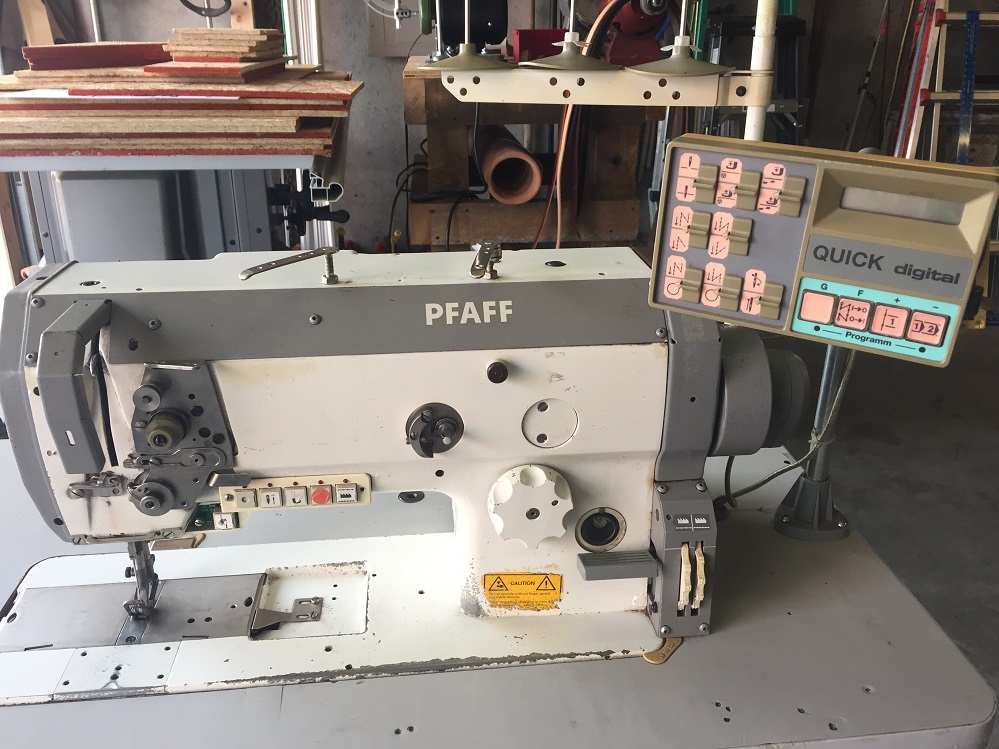

I have a Pfaff 1425 for sale. I purchased it with another machine I am currently using and I do not have the need for this one. It sewed when I bought it last year and I have not used it at all. It is taking up space in my shop and I need it out. Accepting reasonable offers. I don't know much about the machine other than it is 220V and has pneumatic driven components. I may also be up for trading for a less complex, 110v flatbed machine. $850 OBO. Located in Central Missouri Thanks

-

-

Is there a way to edit my post?

-

I have a Pfaff 1425 for sale. I purchased it with another machine I am currently using and I do not have the need for this one. It sewed when I bought it last year and I have not used it at all. It is taking up space in my shop and I need it out. Accepting reasonable offers. I don't know much about the machine other than it is 220V and has pneumatic driven components. $850 OBO. Located in Central Missouri Thanks

-

Has the Item been sold? Thanks

- 6 replies

-

- weaver

- little wonder

-

(and 3 more)

Tagged with:

-

Looking For A Chinstrap Buckle

enginecoleather replied to JerseyFirefighter's topic in Hardware and Accessories

I contacted them and the said they put 700 in stock. Thanks for the link! -

Looking For A Chinstrap Buckle

enginecoleather replied to JerseyFirefighter's topic in Hardware and Accessories

Are you still getting these buckles? -

I attached a few pictures. Where is a good place to get servo motors and anything special I should be looking for? Got both the manuals now thanks!

-

I recently picked up a Singer 153K103 for a price to good to pass up even though I didn't know anything about it or if it would even work for my projects. A year and a half later I am ready to blow the dust off of it and see if I have anything worth messing with here. First off I see that it has a 3 phase 240V motor that I have nothing to support with. Also I have no manuals or information on it at all. So I am curious to see if anyone out there has any advice or experience with these machines and where I should start. Replacing the motor to 110V? Manuals? Parts availability? Pictures will be added tomorrow. Thanks Kale

-

I think i have settled on running 277 thread. The machine operates best with this thread size and and a 200 needle combination. I have ran every size thread and every size needle thru it and have adjusted it in every way possible, but now know the machine just seems to like this the best. Thanks for all the help.

-

The 346 thread wouldn't even pick up or sew one single stitch. I have had the best luck with 415 and actually using a smaller needle than recommended.

-

I will give the 346 thread a go tomorrow when I get home and see where I can get with that. Anymore tips or tricks would be greatly appreciated!

-

I am using the 794 chisel point series needles from tippmann, the size 250 is what is recommended for 415 thread. The needle moves very easily up and down the thread. #27 may be more of what you are familiar with?

-

Yes I am

-

I am having a heck of a time getting the boss set up right. I mainly want to use 415 thread and plan to sew 2 8oz veg tan pieces together with a light 2oz backer. I had trouble when I first got the machine and sent it back to tippmann and they told me my timing was way off, which I don't know how since I didn't mess with any of that stuff. I have been using the 794-250 needle and have trouble even picking up first stitch. The machine will sometimes pick up but wont sew constantly. I have adjusted all the tension as recommended and have lost patients with this machine! I hope this wasn't a bad investment as I had previously hand stitched everything and was hoping to cut down on my sewing time. Any help would be greatly appreciated!!! Kale

-

Thanks Dwight! new to the site maybe i will figure it out. That's what i was hoping to hear. I think i am on the right track

-

I am using feibings oil dye, and I have been spraying acrylic resolene on them afterwards

-

Hello all, I am fairly new to leather work within the last couple of years and I am making leather radio straps for the fire service. I am looking to ramp up my operation. I like dying the leather myself to achieve the color I want. I have been dying them by hand and I finished the backs and edges with edge kote. I am not the satisfied with this process. I use Hermann oak and I am very satisfied with it. I have been looking into "dip dying" so I could do 100 straps at a time and I am thinking I wouldn't have to apply and edge kote to them anymore and finishing the edges would be much easier. I just want to make sure the dye will set in well and I can't have any rub off onto shirts. Any help is greatly appreciated. Thanks, Kale

-

Hello all, I am fairly new to leather work within the last couple of years and I am making leather radio straps for the fire service. I am looking to ramp up my operation. I like dying the leather myself to achieve the color I want. I have been dying them by hand and I finished the backs and edges with edge kote. I am not the satisfied with this process. I use Hermann oak and I am very satisfied with it. I have been looking into "dip dying" so I could do 100 straps at a time and I am thinking I wouldn't have to apply and edge kote to them anymore and finishing the edges would be much easier. I just want to make sure the dye will set in well and I can't have any rub off onto shirts. Any help is greatly appreciated. Thanks, Kale