ZigZag

Members-

Posts

84 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by ZigZag

-

Thanks Michiel for your insights. I’ll have a look tomorrow and see what lies behind the door. I’ll send a couple of pics. I’ve seen Uwe’s YouTube on timing zigzags so will work with that for the time being. thanks. Nick

-

Hi all, today I picked up a fairly well used Adler 98, which I now want to fully service and restore, but I can’t seem to find any manuals online. There is a parts manual and the original sales leaflet, but I’m looking for the ‘how to’ manual. im pretty sure there is something wrong with the reverse function being out of time with something. hoping someone may have something stashed away on this or it’s derivative. i do love a zigzag machine! thanks Nick

-

Recommended machine for canvas and leather

ZigZag replied to ZigZag's topic in Leather Sewing Machines

Interesting choice. My 441 is Typical and I’ve been pretty impressed with it so far. Will give that a look up. Thanks for the input. -

Recommended machine for canvas and leather

ZigZag replied to ZigZag's topic in Leather Sewing Machines

Thanks Doru, I will add to the list. Looks very similar to the Juki 1508 too. -

Recommended machine for canvas and leather

ZigZag replied to ZigZag's topic in Leather Sewing Machines

Thank you for this. I’m now very unconfused. The fog has lifted. -

Hi all, I’m looking to upgrade my Seiko STW8 (copy of Singer 111) to a machine with the following Large bobbin (essential), top loading (ideal but not essential), Tripple feed, heavy duty so large fly wheel, minimum 10mm foot clearance, single needle straight stitch, internal or external bobbin winding, V69 V92 V138 threads, Reverse feed. Budget up to $1500 / £1000 possibly a bit more for the right machine. I recently missed out on a Juki LU1508, which looked ideal, have also considered a Singer 211 (find all the series numbers & letters a bit confusing) Pfaff 1245. any other options I should consider. Thanks Nick

-

Just saw this on eBay. Cheapest I have ever seen one here in uk. Need to be quick though. Less than a day to go and low buy it now price. Good luck. I’d buy myself, but I’ve already got one https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.co.uk%2Fulk%2Fitm%2F263927001186

-

Thanks kgg, that is super useful and a brilliant piece of calculation. The 563 is looking like a very interesting option. Thanks Wiz, I’ll have to look into this in more detail. A font of knowledge as always.

-

Thanks pinto, I will be using the machine in a mix of canvas for boat covers and bag making with combined leather & canvas. appreciate the thought. Nick

-

I’m looking to replace my Seiko STW 8 (same as Singer 111) with a large capacity bobbin machine. I would prefer an older used machine and must be compound feed. i have used the Seiko LSWN before which is a nice machine but don’t see many come up for sale here in the UK Any suggestions? thanks Nick

-

Newbie looking for sewing machine. Opinions on Sailrite?

ZigZag replied to Aurita's topic in Leather Sewing Machines

I own the the Sailrite LZ1 and in many respects is an excellent little machine. But as mentioned above the foot lift height is very restrictive and the working area under the arm is very limiting. I have sewn veg tan leather to canvas before and it struggled a fair bit. I think you would become quickly frustrated with it. I now use either a Seiko walking foot (same as Singer 111) or my 441. You really do need the right machine for the job. good luck Nick -

I have recently been asked to go over Singer 211 that has been donated to a charity I volunteer at working with recycling old sails and marine canvas to help disadvantaged kids. It looks like the timing is all over the shop so I’m starting with the belt timing top to bottom shafts, which is pretty straight forward. My question is where to go next to make sure I work through all adjustments in the correct order. It seemed to make sense to make along to the feed dog, but there again maybe not. Is there a best practice order of working through a machine. After this one I have 4 singer 111’s, a pfaff 563, a reads sailmaker, and a singer 99 that all need checking over. Thanks for any pointers. I have manuals etc and have worked successfully on my own machines. I guess I’m looking for a 1-10 order of attack. Nick

-

Pfaff 138, general info wanted

ZigZag replied to BaroqueLeatherGal's topic in Leather Sewing Machines

Needle size 19 with V92 top & bottom. -

Pfaff 138, general info wanted

ZigZag replied to BaroqueLeatherGal's topic in Leather Sewing Machines

Hi, I have the Pfaff 238, which is essentially the same machine in a different casing. It is a brilliant machine and certainly tough enough to go through leather. I have done sone work on upcycling motorcycle leather with it (3.5 to 4 mm total thickness) and it has worked really well. If using the zig zag settings don’t use a leather needle as the diamond shape hole isn’t suitable. i have changed over to a servo motor which has made a huge difference to the usability. Enjoy Nick -

Hey Matt, I bought a typical 441, which is excellent quality. I paid £3000 with servo motor and speed reducer all delivered by an engineer to demo it working etc. One or two of the US brands are relabelled Typical machines I’m told.

-

Hurrah! Success. Uwe & Cowboy Bob, thank you so much for sharing your knowledge and experience. Uwe, your video was a huge help and you were right, the bolt on the inside end of the bar wasn’t very tight. Also your visual guide of the arm being fully in or out at tdc/tbc was perfect for figuring it out. I did loosen the collar with the cam as it was slightly out. But so easy to get right with you help. All back together and working better than ever. The sewing machine doctor does it again. Nick

-

Thank you both Bob & Uwe for you advice, I’m back to work tomorrow so will have to wait to put your thoughts into practice. Much appreciated. Hold tight, response coming soon. Nick

-

I have sat staring at the 441 for a little too long now, but it appears the timing between the needle bar and the inner presser foot and the offending item. When the needle bar is coming down the inner presser foot is going up. No matter how I adjust the driving shaft arm, it’s is always out of sync. Something elsewhere has come out of alignment. So frustrating as yesterday it was bang on the money. the tightness that lead to it shifting out of whack looks like it came from the driving shaft arm needing to be pushed in firmly home. When I changed it yesterday it was only a half mm out but enough to create some unhappiness.

-

I’ve tried a different setting from a manual for the cam but I’m pretty sure it’s in the correct position, which leaves me none the wiser. Something has definitely gone out of whack. I guess at least I’m getting to learn more about the machine. Any clues?

-

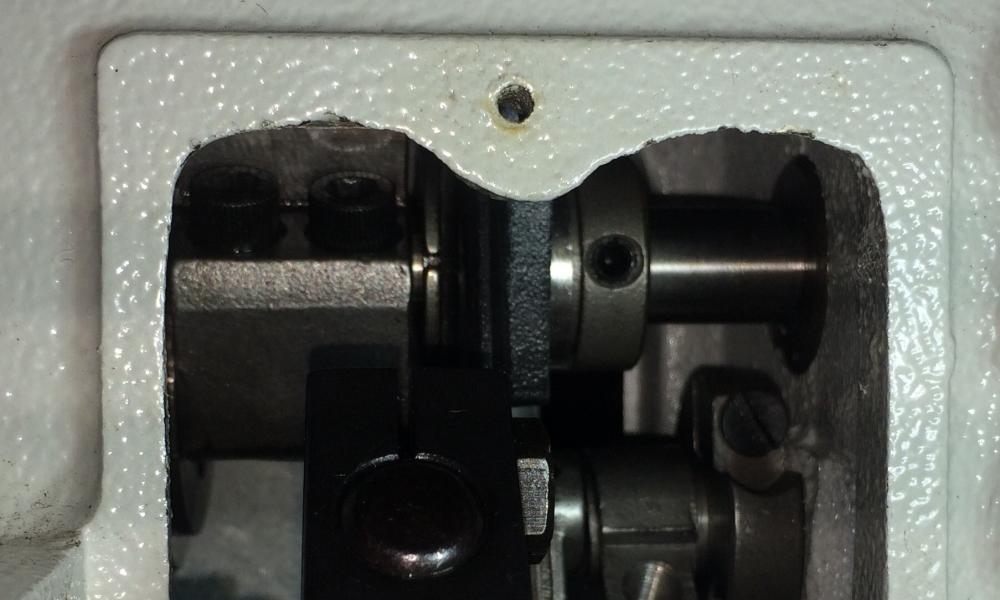

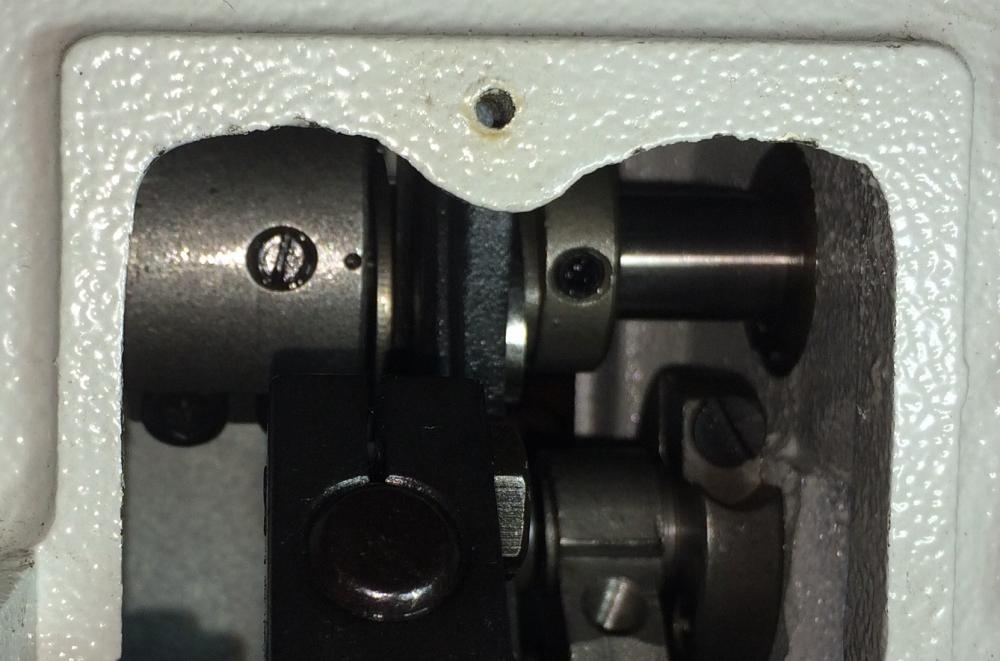

It wasn’t to do with the adjustment mentioned above. Now looking at the feed cam as possible problem. I’ve attached a couple of pics of where the feed cam is currently positioned. There are 2 manufacturer marks, which I think line up with the set screws. Does this look right? Thanks Nick

-

Mmmm, tried again with this today and the adjustment we’re talking about isn’t the issue. I had it timed perfectly yesterday, but at one point it did feel like it tightened up and then it sounded like a shaft slipped in its retaining collar somewhere. i have looked at another manual and think it may be what is described on page 6, No 19 referring to illustration 16. Fingers crossed TY_manual_TW3-441_en_01.pdf

-

Thanks Uwe, will try this in the morning and see how I get on. Could be I didn’t follow instructions carefully enough. Thanks Nick

-

Here’s a quick video of what it looks like. Nick 063053D7-F34F-46D2-B944-69B33F430B75.MOV

-

I have a Typical 441, which is much like the other clones available. Since I’ve had it the inner and outer presser feet have never quite been in sync so I made some adjustments as detailed in the attached pdf. Page 8, which worked a treat, but then something elsewhere seems to have been thrown out of time as the inner foot has now got a limp and is hardly lifting at all. i decided to go through Uwe’s video tutorial for timing everything, all of which went well and I have fine tuned hook, needle height etc. Thanks Uwe for your downloadable balance wheel degree rotation diagram, works brilliantly. I’m quite happy working with machinery, but can’t figure this one out. I’d be grateful for any advice. thanks Nick TSC-441 Adjustments.pdf

-

Hi Jack, I have used the sailrite LZ for a few years now and think it is an excellent machine, a tad clunky and the workspace under the arm can be a real draw back. I have also used the Pfaff 138 and 238 for quite a long time all for marine canvas, sail repairs etc. The 238 is simply an updated model of the 138, both come in different stitch widths 4.5 mm zigzag model A or 6mm model B. They are both super slick, smooth and quiet machines and a joy to use. Both are definitely industrial machines. The stitch width is easily adjustable and selecting ‘0’ gives you a straight stitch. Both machines have forward & reverse and also the ability to shift the needle to left, centre or right when in straight stitch setting. The 238 model has the addition of an oil bath with wicks that feed essential points in the top end. Underneath are two bevel gears that require grease or I quite like a recent suggestion on here of using motorcycle chain lube which is sticky and won’t get thrown out of the gears so much. there are also various oil felts throughout the machine to maintain consistent lubrication. i believe some 138 machines came with two spring tensioners for using twin needles, but I’ve never used this option. They are very solidly built and can easily handle V92 thread, but the bobbins are pretty small so using a V69 will help with less frequent changes. I was so impressed with the one I used at a sail based charity I help out at that I bought my own 238 recently. Nick

- 1 reply

-

- zig zag

- industrial

-

(and 3 more)

Tagged with: