councilman24

Members-

Posts

87 -

Joined

-

Last visited

Profile Information

-

Location

SW Mich

-

Interests

Sewing machines

Recent Profile Visitors

4,363 profile views

councilman24's Achievements

Member (2/4)

-

Tension has nothing to do with skipping stitches. When the event of stitching a skip occurs the top tension has been released by the take up arm coming down. That thread does not look like sewing machine thread. The fibers stitcking out makes it look like twine. Remember each point on the thread goes back and forth through the eye of the needle 10, 15, 20 times depending on the stitch length. As the hook pulls top thread around the bobbin and the take up lever pulls it back, leaving only the length of a single stitch behind. And depending on the speed your stitching and the amount of thread pulled through the eye it can be moving 20 to 30 miles per hour. Reversing back and forth for every stitch. Exactly what is that thread? Sewing machine thread usually isn't T80. If you want to keep trying that thread go to a 22 or 23 size needle. But first I'd get it working with right twist bonded nylon T70 thread. Yes the left needle should use right twist thread but unless your a factory buying it by the pallet load it is rare and only available usually in white and black. Most of us manage to get left twist bonded thread to work on the left needle.

-

Adler 205-370 - help an old man who screwed up

councilman24 replied to councilman24's topic in Leather Sewing Machines

This is the only machine that has this spring loaded shuttle race. Unless Adler's new one, 969 I think, does. -

Adler 205-370 - help an old man who screwed up

councilman24 replied to councilman24's topic in Leather Sewing Machines

Not that I can find. Found one on setting neesle bar height bit not on turning shuttle timing. I figured it out and it's sewing but don't know what I don't know. -

Adler 205-370 - help an old man who screwed up

councilman24 replied to councilman24's topic in Leather Sewing Machines

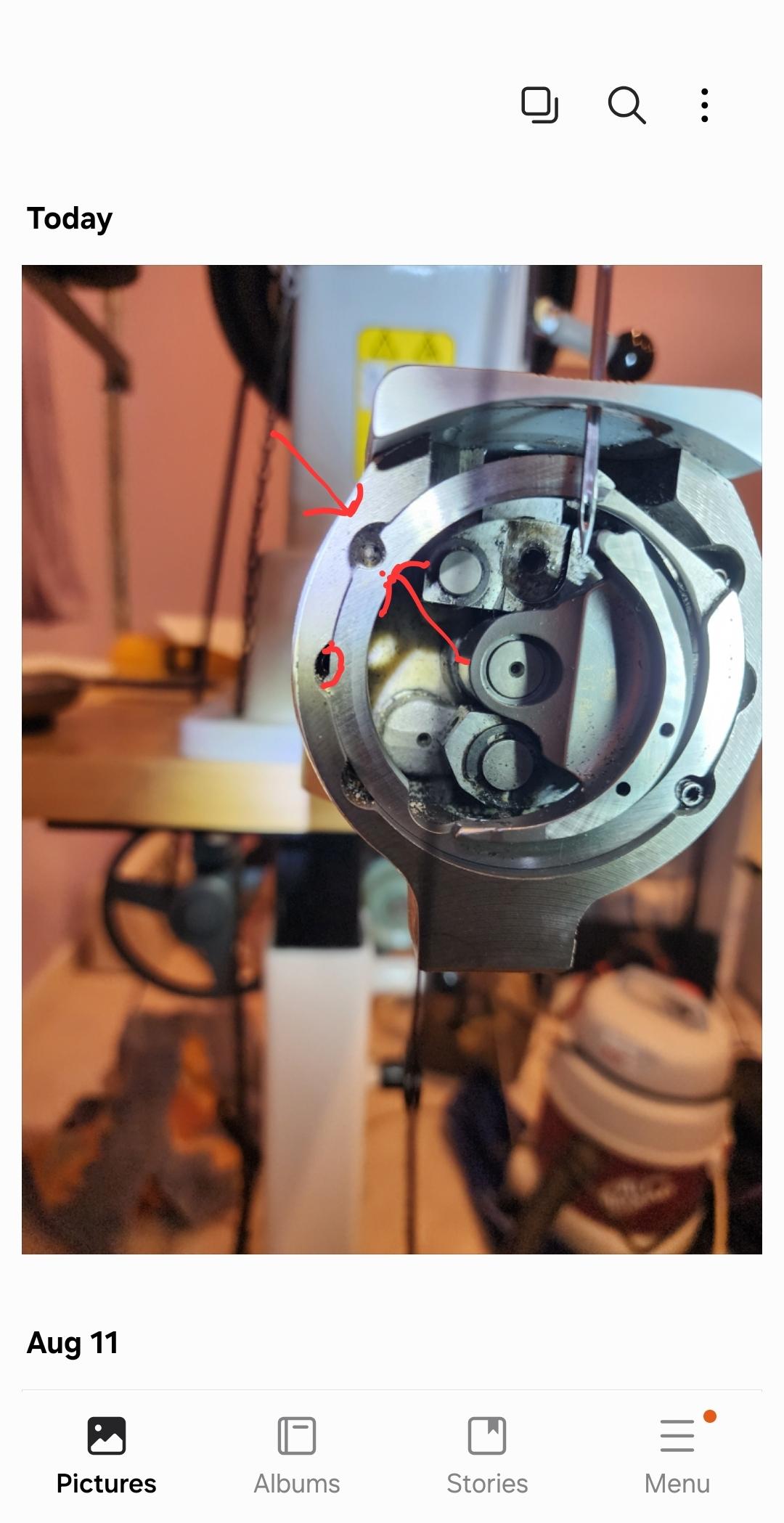

I just figured out the trick to get the inner race in. I couldn't get it in with the springs in place. But you can with the springs out. Then you can turn the race to match the half circle cut outs in the surrounding structure with the half cir le cutouts on the race. Insert the spring. A needle helps with line up. Then turn handwheel to allow race to turn and line up another spring. Got all four in, lined up race cutouts for for door assembly bolt, and then pressed in and locked ba k with ser screw. In photo you an see one spring in and hole lined up for another. This is the kind of trick that can save hours. And obviously was intended with half cutaways in stationary out side rim. I was trying to figure out why those cutout were tpmhere. That's what led to figuring out how to do it. -

I was trying to get a parachute harness job done last night. I went to rethread the machine and like the forgetful old man I am I forgot to thread through the hidden take up lever. Yes I know, but I haven't had it long, it was 3 am and I'm forgetful. I actually teach new riggers how to sew so yes I no better. So, or course a bunch of thread got bound up around the hook and bobbin. I cut the work loose, opened up the cover, pulled out the loose thread. Hand wheeled around and the needle was hitting part of the hook. I was confused and pulled door assembly off and pulled hook out. Of COURSE, I forgot to tighten the inner race spring lock. By the time I remembered about the lock I had managed to pull the inner race out from behind the hmm, hook driver? What ever that part is called. And now I can't get it back behind to lock it back in place. I did manage to find the one spring that fell out. Any help on how to get the inner race back there without complete disassembly? I got it out but I've tried an hour to get it back. Also it seems like the timing is off a lot, like 180 degrees. Do the two halves of the drive shaft under the clamping rings slip around one inside the other? The timing instructions in English are poorly translated and confusing. Given that I have to retime the bottom anyway maybe releasing the clamp rings and what ever I have to do to get the driver out won't be much more. Any videos on timing hook? Couldn't fine any from Uwe or anyone else. Help? Photos in a few minutes. Terry

-

Bobbin Shim for #280/#300 Needles

councilman24 replied to AaronStand's topic in Leather Sewing Machines

Replying to an plder thread I read a couple of days ago. Cambell Randall has 300 shims for the 205. Their online catalog sucks so call them for what you want. I just installed a 300 tonight I got from tbem a few weeks ago. -

Adler 205-370 reverse friction.

councilman24 replied to councilman24's topic in Leather Sewing Machines

Yep, finally got back to it. About 30 secs to fix. thanks. -

Just acquired a 205-370 in excellent condition. But when moving the stitch length lever into the reverse/up position it tends to sag slightly. Is there some friction pad/device that may be worn or other fix or adjustment to hold it in place against gravity? I tried to look inside but chose not to get.too carried away yet. And I couldn't identified a thing on the parts diagram but the scan I have isn't very high high resolution.

-

As above 280 /28 the metric size and US size respectively of the blade of the needle. If the needle is 2.5mm in diameter and 60mm from the top to the top of the eye it is likely (or is equivalent) to class 7x1 (aka 794). The larger adler (204 and 205) and cowboy machines as will as the singer 7x33 class and consew 733 use 7x1 (leather) and 7x3 (cloth) (aka 794) needle class. I have Adler 205, Singer 7-33, 7-33 and singer 144's machines that all use 794 class needles.

-

Sewing needle again , 134 /135-5 and 135-17

councilman24 replied to Bananaman's topic in Leather Sewing Machines

It will NOT sew with a 135x17 if timed for a 135x5. The Pfaff 238 actually came from the factory in both set ups. Attached is a screen shoot from a reference in a Facebook group file section that has all the specs for each needle system by every equivalent system and fullncross reference of needle systems. https://www.facebook.com/share/p/Bzpqr2PA3UDL3JBF/?mibextid=oFDknk BTW There are dozens of needles that start with 134. Not all have the same shank dimensions. -

There are 217's that cam with a small size cam box. The 217n model generally was supplied with a larger size cam box. The 217n also supposedly cam with a small cam box. I do not.know but don't think it was the same as the 217 small cam box. The 217n also came in 6,8, and 12 mm max zig zag width. As the post above shows the cams are NOT interchangeable. I have 308 and 315 cams for the 217 small cam and a 308 8mm cam for the large 217n cam drive. If you haven't figured out I have both a 217 and a 217n 8mm and 12mm. Global only sells the 315 4 point zig zag cam. 12mm width I think. So when talking about a "217" you should specify either 217 or 217n and max stitch width.

-

Moving Industrial machines around the shop and outside

councilman24 replied to Dave9111's topic in Leather Sewing Machines

I think I'm the one that started the Hoyer lift recommendation. At least started recommending it a few years ago. I use it to lift entire tables with machine from the end. Using a couple of adjustable straps I made. Since it's made for moving up to 400lbs through doorways it works well. I also use it to lift 166 lb Class 7 heads and 30" long arm 144's. Working on a Class 7 when you can reach the top and the bottom of the head is a whole lot easier than reaching or crawling under a table. I've also used the lift to put them in and out of a van or truck. They go under the vehicle just like a bed. I have about 18 head on the first floor of my house and another 35 or so downstairs. So I bought two used lifts. For around $75 each. Often left over when an elderly relative moves to a care facility or passes. Living alone most of the time the lift makes it easy for me to move all but the biggest tables around. -

I didn't put this in for sale because I don't own it or possess it at the moment. But there is an American straight needle available in Southwest Michigan. My understanding is that it either sews or is very near to sewing. It would end up being at most a few hundred dollars. If anyone's interested in discussing further send me a message. For more explanation it's part of a deal that I might do but have absolutely no room or need for an American straight needle.

-

I think it may be they took off the jump foot but didn't add anying else. Still not sure?

-

Trying to figure oit what the difference between a 132k6 and k10 is. I found one indication a k10 may either be a true walking foot or at least something different that the spring jump foot on the k6. Anybody know? I'm tired of trying to find some thing besides the parts manual and to cross eyed to sort through parts to figure it out.

.thumb.jpg.181dc931617f460b509ff2b5d390be96.jpg)

.thumb.jpg.4d7f5b43fa79435520f2c278e37fd124.jpg)