-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Yetibelle

-

-

That is a good question. I don't think it will hurt the machine to sew wet or moist leather, just wipe it down and re-lube after your done.

I have been making some rather large round leather sandbags (about 3-5 pounds). I also found that it is less work if you wet the thick leather and then sew it, however if the mold is going to pull on the stitching as it dries you may get some stretch marks. Also if your sewing wet leather then I assume your not gluing the edge. That brings up the whole project workflow. First mold your project and clamp the edge to the right shape so you can sew it once it has dried, then prepare the edge with glue, then clamp and let that set-up, then sew the edge and burnish it. I suspect those are the correct steps, but if your not using glue and don't mid a little stretch in the project then there is no harm in sewing it wet? Lets see what Wiz has to say....

good topic

-

Really any vintage\antique machine in that nice of condition is worth 90 Euro.

-

1 hour ago, Parfektionisto said:

Hi Yetibelle,

The deck-plate looks awesome, may I know what subclass is this 45k? Does the deck-plate fits all 45k cylinder bed?

Tony

They are from a 45k76 machine. I can measure the plate when I get home and post the measurements. I would think it fits all the 45k arms but you never know.

-

"when the owner dropped the machine".

Well at least you have a starting point. If that is the only thing wrong with it you may be lucky I suspect it may have other issues, look it over well.

-

Without pictures its hard to guess the exact problem. I suspect the race plate is too tight and not letting the thread move around the shuttle correctly? That is just a guess.

-

Thanks for making those video Uwe they are excellent!

-

Well there are plenty of comments on the Tippman hand machine. If you get one cheep and working it's worth it, but most of them sell used for $800 plus so for that much you can get a good used motor driven walking foot machine.

-

I'm not familiar with any repair manuals, there are just parts manuals and user guides. There are also troubleshooting pages sometime at the back of the user guide "Instructions for Adjusters and Machinists" that go over how to recognize and fix common issues like replacing the internal belt and adjusting the timing, setting the needle bar, ect. If your planning to take the machine totally apart I'm not aware of a compete manual for that level of detail. I think what most of us do is take pictures of each stage as we take parts off, then use those pictures to put it all back once they are clean or replaced.

-

1 hour ago, YinTx said:

It seems I've either missed it, or no one has asked... what do you plan to sew mostly? I have both machines, and a lot of stuff the 4500 simply won't do for me because of the thickness, such as one layer of <4 oz leather to canvas. I suppose if you were an expert and could finagle the machine, it might do it. Otherwise, the smaller machine is the tool for the job. I even have difficulties getting the tensions right on that one with this combination. However, once you have to double up and have 2 layers of leather and 2+ layers of heavy canvas, sometimes the little machine won't step over the hump so to speak. All this being said, I am far from an expert, only having struggled to sew a few things on the machines I have. Just thought someone should pose the question "what is the intended use of the machine?"

YinTx

I decided on the CB4500 since it will give me the most versatility, the longer arm, the higher lift, ect. I will be sewing an average of 1/4 to 1/2 inch most of the time so the CB3500 would have worked but I think I would have tried to push it sometimes and then ended up getting frustrated. I know this because I did this with my 111w155, I kept trying to run heavy thread and bigger projects than the machine is meant to handle. I could get it to work sometimes, but other times I would just get the machine clogged-up. So rather trying to force the machine to go beyond the limits I took the advice and got a machine I could grow into.

I am sewing leather and canvas bags and organizers (I need a better name for that). I have been looking the last few years for a Singer 97-10 or Singer class 11-22 or similar, I have not been able to find them locally for any reasonable price so I decided to go for a the Cowboy CB4500 since it has all the features I was looking for (plus reverse) in an arm machine, that can also be converted to a flatbed. I really love the old machines and I will still keep restoring them, but I wanted a dependable machine that could I can use everyday.

-

9 hours ago, KeithHideWorks said:

Do you mind explaining why the inline foot would cause you to lose throat? Looking at running that with a 4500 and not sure I understand.

Thanks,

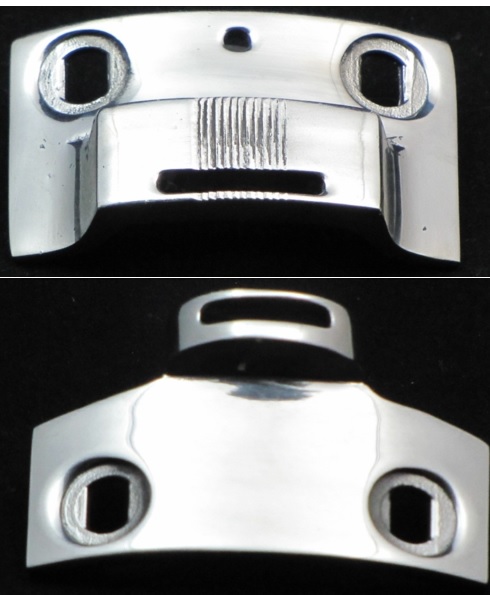

I think Wiz was referring to the Holster and Stirrup plates. They have a raised surface for fitting thicker leather under the foot, but because they are raised you loose some clearance under the foot. You can see how they are shaped in the picture. The distance between the throat and the needle will be about the same. I suspect you only use these plates on smaller thick projects that need the lift. I assume you would use the standard plate most of the time.

-

Looks Good. I love that base.

-

13 hours ago, Uwe said:

I'd stay away from Ebay until you know what you're doing - it's a gamble under the best of circumstances.

Buy from a reputable dealer or somebody you trust. Most people on Ebay do NOT know how to ship a sewing machine and thousands of machines have died in transit.

In general, industrial sewing machines are designed to sew whatever you can fit under the foot. Look for unison feed (bottom+top+needle) machines with at least 10-12mm foot lift.

Resist the temptation to change the question every time you get an answer.

For sewing multiple layers of leather, a bottom-only feed machine will not make you happy.

I think this is my new meditation chanting mantra:

"Resist the temptation to change the question every time you get an answer."

-

I think this is the one.

Goto: www.consew.com/Files/112347/InstructionManuals/206RB-5.pdf

-

Yeah - I saw that CL post, that looked like a really clean machine for the 3 minutes the listing was up. Good score! Haha

Yes get a servo motor for it, they have a dial you can slow them up and down. They are about $100-$130 on Amazon. Very easy to swap out.

-

I really like the 29-4, they are fun machines. I found some 29-4 sew fine straight but when you go to turn the head they start to fail. I have been told this is due to a worn part in the head that can be replaced but that part is typically $30. So when you test the working machine make sure it sews as you turn the head and the stitch length is consistent. Having the second machine for parts is nice but most if those parts you may never need. The $450 includes the treadle base, or just to machine heads?

-

I struggled with "what machine is good for me" for the last few years. I am glad I started with old antique machines so I could get use to the big machines before I got a new machine. Chances are the first machine you get will be good but you will realize you should have got a different one. I recommend finding a good used machine and spending as little as possible starting out. You can practice and get over the learning curve for less money.

-

4 hours ago, Uwe said:

Some Singer Class 7 models can be retro-fitted with reverse. The lever is on the back and usually operated via foot pedal or pneumatic cylinder. With the right motor control you can even program automatic back-tack and other tricks. Adjustment screws at the top and bottom allow to balance forward and reverse stitch length. Here's a picture of my 7-31 that has the retrofit reverse lever:

I'm looking at that motor setup you have there is that just a portable testing motor you rigged-up?

How can you tell/identify the Singer Class 7 models that can be modified for reverse?

-

Those are good points I didn't factor-in the throats plate "math" in my thinking. How many foot and threat plate options are there for the 4500? I figure I would be working with the inline-foot and the left\right foot for narrow side lines. There are custom plates that people have made also if I remember right.

-

13 minutes ago, Double Daddy said:

I believe Bob at Toledo Sewing had some used CB4500's in stock at a STEAL (saw it on his FB feed the other day)...as in a similar price to a new CB3200...plus, he and his staff goes over them to make sure they run right (like they do all their machines) before they go out the door...worth a look to see if one's still available...may have all been snatched up already.

Well that may be the option I will check on that tomorrow and see what they have in refurbished. So far that's 2 votes for the 4500.

-

l was sooooooo close to talking myself into a 4500, that I just talked myself out of it. Darn...... I'm sure other must have struggled with this question so I'm looking for how you may have worked this out. I technically own a few machines, but I have never had a NEW machine and now I'm ready and just can't narrow it down. I want to run the heavy thread but in reality I don't see myself sewing thicker than 1/2 inch on most projects. I like the idea of the longer arm but Is it worth the extra $700 for 415 and extra arm space? Why can't the 3200 run the 415 thread if they use the same needle and hook? Last - What about the 3500 is this the compromise?

Yes I do plan on calling Toledo - but also looking for what others may have gone through picking there first NEW machine. Thanks

-

I say any vintage or antique machine head that is 80% or more complete for under $100 is worth it. Especially if its on your list of machines. As long as its not damaged or some other abuse (turned into a tractor - Blasphemy!).

-

Sure the old Singer home machines are really tough and can sew just about anything most of the time. I have a few of them myself, however if your telling me you have $350 to spend on a vintage machine, I would not recommend that 15-91, you should look for a Singer 111w155 or a Singer 29-4. If you want to stick with a vintage home machine look for a Singer 201-2 it is a little bigger than the 15-91 with the same direct drive motor. If you like the hand wheel option look for the Singer 29-4 machine they can use a treadle or a hand wheel. So many options..

-

Also $350 is a lot for a 15-91. you should be able to get one from CL for under $150 most of the time. Plus they kind of wrecked it putting that hand-wheel on the way they did.

-

I will see if I can beat Wiz to the punch here.

Sorry its not a real leather sewing machine. While it may work for really thin projects, it does not take the thread that you really need to sew leather like at least a #69

See Wizcraft's post on leather sewing machines.

Clone family tree

in Leather Sewing Machines

Posted

I see what your getting at, but "most" (see I said most for all you German machine heads) of the technology going on here was invented 100-150 years ago and then dominated by Singer. So unraveling the clone family tree really isn't useful since I doubt you want the original machine most of these new machines are based on. Also I suspect you want reverse on your new machine? So when we toss-around clone for leather machines it typically refers to the Juki 441 machine ( Cowboy CB4500) (Cobra P-4) that most of us will recommend (I got min CB4500 a few months ago and love it BTW).

However the pro\cons of antique or vintage machines over new, that is always a good topic. If you want to sew a product that your going to sell, I suspect you will want a good running machine with reverse, that will be working in production. If you want to do this as a hobby then you could get a used antique machine, but the sewing machine restoration learning curve will consume your time (maybe all your time) to get the machine back to 100%. So if it is sewing you want to do, save up for a good new machine. If it is antique restoration dive right in, it will only cost you time and less money to start but you wont do much sewing at first.

Hope that helps.