-

Content Count

358 -

Joined

-

Last visited

Posts posted by Yetibelle

-

-

Haha - the 969 - that's funny! Now I know your kidding but you do bring up a good point. How much better does the 969 actually feel? Did they name it after the Porsche? Is that kind of good? Darn now I want to try one out. Thanks for adding that to my OCD list.

-

Really the older home machines can do a great job. But swapping out the foot still won't help you. The irule of thumb for any machine. If it fits under the foot you can sew it, if not you need a bigger machine. The feet swap out for different projects but they don't change the function or limits of the machine. All the feet for that machine will still have the same lift.

Do you have some picture examples of what your sewing?

-

You need to take the thread up over-the-top - then down to the bobbin winder through the tension disk. See video example.

-

Wow - well I'm impressed that it will sew with the #69 thread, but that would be the limit. Since it is a 15X1 home needle system, It wont take "bigger needles", or heavy thread. It can use a 15x1 leather point needle that will help it a little. It's just not designed for that.

-

Your projects look great, I think this would be a good machine for that type of work.

From the description, I like the Techsew 3850, it looks to be a good value for 7X3 machine. It's not a big deal swapping needle and thread size and then adjusting the tension, however keep all your scraps since you will need them for test strip as you change the settings. Plus you don't have to change the thread size per project. There is no rule you have to use 92 for wallets and 277 for bags, you can use whatever thread you like. The heavy thread just changes the look of your project.

-

NICE find. Looks like a good clean machine.

Here is my advice - Get some eye protection safety glasses, especially while practicing with that clutch motor. If the needle gets pulled one way or the other it will hit the hook or needle plate and snap, then head right for you eyes.

I do notice that you have the welt foot on there, It's harder to sew a flat or straight line with a welt foot (unless your actually using it as a welt foot). So your going to want to get a some feet for it. I use the spring loaded edge-guide foot, but some people just like regular feet and a magnet or screw-on guide attachment. Someone once told me you run one size smaller thread on the bottom than you do on the top, so 92 bottom 138 top, for best results. Once you get comfortable with the machine you can set it for 138 top and bottom but I have found it also depends on how thick of a project you sewing. A little trick with the Singer machines is that you hold the top and bottom thread gently so they have a little tension on them as you make the first few stiches. This helps lock the first few stiches in place. Also if you want to sew by hand turning the wheel with the Clutch motor, (off) you need to press the petal so it opens the clutch and you can then turn the wheel, otherwise it will be hard to turn. However you will want to replace the motor as soon as you can.

If the internal timing belt was ever replaced, sometimes the numbers in the window don't line up with the stich-count adjustment, its not a big deal, you just have to be aware of it.

Needles: The 135X17 are for canvas and fabric --135X16 are for leather they will have a chisel point on them.

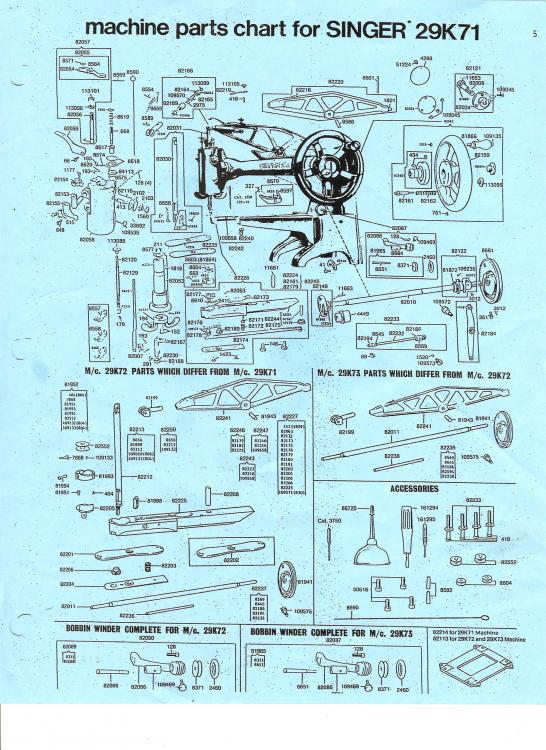

Scan of the guide:

https://drive.google.com/drive/folders/0B8SsIFb6Bqz7bnNlY2ctcktpWTQ

Enjoy I love my 111

-

8 hours ago, Constabulary said:HOW FREAKIN COOL IS THAT?

I was not even thinking of that as a DIY. Maybe an idea for making "blue guns" for holsters out of aluminum or brass (cartridge shells?)

I was not even thinking of that as a DIY. Maybe an idea for making "blue guns" for holsters out of aluminum or brass (cartridge shells?)

Male weekend: drink dozens of beer - make fire - melt beer cans - use foundry for grilling some sausages - drink more beer - melt more beer cans - cast blue guns

What else do we need, Beer, barbecue, fire, guns

Yeah this guys YouTube feed is great he has a lot of simple machines you can build. Look for the one he makes an arc welder from a microwave. Good times

-

Well how about a class 29 machine? Like a 29-4? They can be had for $300-$500 bucks. Still an arm machine. If your only making 20 or so bags that would be a great machine.

-

When you see the" thread-nibs" on the top or bottom it's a tention issue. Plus that's a corner. Corners are hard in general.

-

Anyone can sand-cast at home. It isn't that hard to cast one from aluminum. This is a fun weekend summer project.

-

That replacement "Cast-Off Screw" looks a little out of place? So that was a trouble area already on the machine I suspect. Here is the guide

-

I love my 111W155 it is my default machine. They are easy to tune and parts are easy to get and don't break the bank. Swap out that old motor with a new servo motor and your ready to sew.

-

Just wondering what do you mean by - "nubbies on the bottom of the seam"? Track marks from the feet or can you see thread "knots/loops" in the stitches from the bottom?

-

That sounds like an average deal, depends on the condition. However when you see a great deal on a Mitsubishi, it typically means it needs a lot of work. Mitsubishi makes great machines, but now your adding a new learning curve, each company brand has it's own set of "tweaking". Your getting use to the Juki and now you will have to add the Mitsubishi. Who knows you may like it more. haha Also you will have to keep an eye out for Juki and Mitsubishi parts, rather than just Juki parts. I suspect the Mitsubishi parts a more expensive. Just a thought.

-

First let me say I am very impressed that you have hand-stitched 5 saddles. That is a lot of work, WOW. The thread that you hand sew with is really thick and I suspect and maybe waxed? In the machine world that would be close to thread size 346 or 415.

I would say the machine you want is the Cowboy CB-4500. You can see the adds in the banners section for them.

Here is one making a Saddle.

-

-

1 minute ago, shoepatcher said:It has to do with restoring the "figure 8" on the end of the bell crank. The lobes wear down on each side and that causes the stitch length to shorten. If someone is a competent welder, the lobes can be welded up with a Tig or Mig Welder and reground with a Dremel and you are almost good as new. I have 30 plus bell cranks from Adler and Singers that have to be welded and reground on the lobes. That is a project for when I retire. That is normally the only thing to go wrong with a used bell crank.

glenn

You don't happen to have a few pictures of the worn parts and what the new/restored parts are suppose to look like?

-

There are a few 29k restoration links out there.

http://northants-restoration.blogspot.com/

This one is a word doc, with pictures not sure if the link will work in here?

-

This brings up a question. For making canvas and leather bags, would it be better to have a Cylinder Arm, or a Post Bed machine? Can't the Post Bed sew tighter corners?

-

I'm going to go with 96k4.

Opps left of the 1

96K41

Final Answer

-

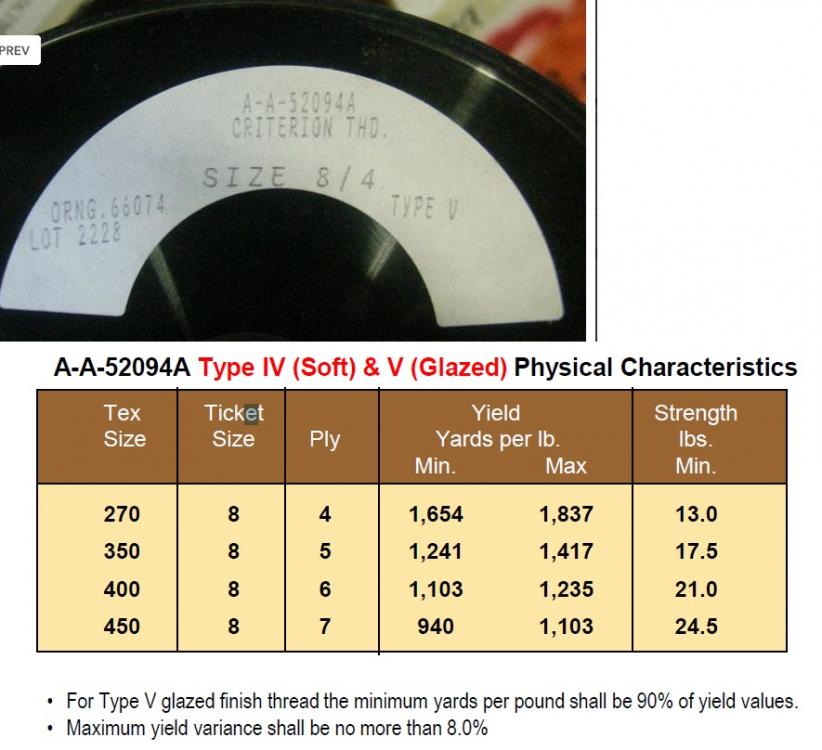

It's always fun to learn new things. Apparently the US Government created its own standard for sizing thread (who knew - ok probably everyone but me). There is a pallet of thread cones on the auction site so I had to look it up. If you ever see a pound of thread with odd numbers and letters, it probably Government issue. I attached the conversion chart.

--plus if anyone wants 400 pounds of thread (in orange), I suspect its a good deal?

http://www.govliquidation.com/auction/view?auctionId=12053791&convertTo=USD

5-Thread-Size-Comparison-Chart-2-4-10.pdf

-

Thanks tricky - What machine model do you have and what feet would you like to use that you can't use?

-

3 hours ago, SolarLeatherMachines said:What RockyAussie said.

As a Cowboy dealer, I can tell you that the CB-4500 is NOT the kind of machine you need. NONE of the 441 clones are going to do what you need. You need something with a very small foot and a very small needle to end-of-arm distance to make the small edge margin stitches.

And ideal machine for this would be a Post-Bed machine with a Power Roller Foot. I think Bernina makes something like that.Unless your making wallets like this!

-

Well I was thinking that the needle and thread that Techsew 3850 machines takes may be bigger than you want to use or need. I'm sure it would work, but it may not be the look you want.

This is the Cowboy CB-4500, it will sew heavy leather, but I bet it would also sew lighter leather, it just makes bigger holes.

Singer 97-10 Users? Questions

in Leather Sewing Machines

Posted · Report reply

The US Army Field guide has a great section on the 97-10 (also the 7 class). Its too big to attach so here is the link. Plus the parts link pdf. Let me know if they don't work.

https://drive.google.com/file/d/0B8SsIFb6Bqz7djdfT19ZWEh3dzA/view?usp=sharing

https://drive.google.com/file/d/0B8SsIFb6Bqz7U2lUbS0wazQtdzg/view?usp=sharing

https://drive.google.com/open?id=0B8SsIFb6Bqz7YnFuUVVaT0UybGc