-

Posts

358 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Yetibelle

-

-

I think Wiz is referring to the Knob you can add to the hand wheel. There is a spot on the hand wheel you can drill and then add the knob so it makes it a crank.

Also - you can get a few parts and move the hand wheel to the side of the machine. Those parts can be hard to come by if they didn't come with your machine.

-

3 hours ago, Jason046 said:

For the most part I'm sewing 2 pieces of 8 oz leather together. I was meaning towards cowboy but there is an industrial sewing machine retailer in my area and most of all they sale is juki and Adler and some other chinese manufacturers. The plus with that company is them servicing and assisting with any problems along with hands on help when buying from them. The machine I'm looking at from them is equivalent to a cb 4500 but they are going to put a speed reducer on it to slow it down to help me with the turns. This is what we saw for the most part

First the CB4500 does come with a servo motor and a speed reducer pulley installed.

I like supporting a local company when possible plus it will save on shipping. However that said if the machine is "setup" correctly and oiled regularly you wont have any issues with it for many years. The real work is getting the machine "dialed in". I have checked with local industrial sewing vendors and they wanted almost double the cost of the CB4500 for the Highlead version. Yes they are almost the exact machine and if I had not unboxed and assembled a factory direct Highlead machine and table for a friend last summer I would not have noticed all the adjustments that go into setting up a Cowboy CB-4500. So I guess what I am saying is there is value in both options and Cowboy is quality machine and a great value . So if the local company prices are competitive, and you feel it is a reputable place that will be extra helpful, then it is worth considering.

-

I have been using the CB4500 with @uwe flat-bed table. I like Uwe's flat-bed because it has a seamless fit over the arm, unlike the standard flatbed table that leaves a gap.

So with this you get a true flat-bed and an arm machine, thus making the perfect machine!

-

23 minutes ago, buzzardbait said:

I had a Boss for 3 years and used it quite a bit. The happiest day of my life was the day I sold it.

WOW - I thought I was hard on The Boss, that's taking it to the next level.

-

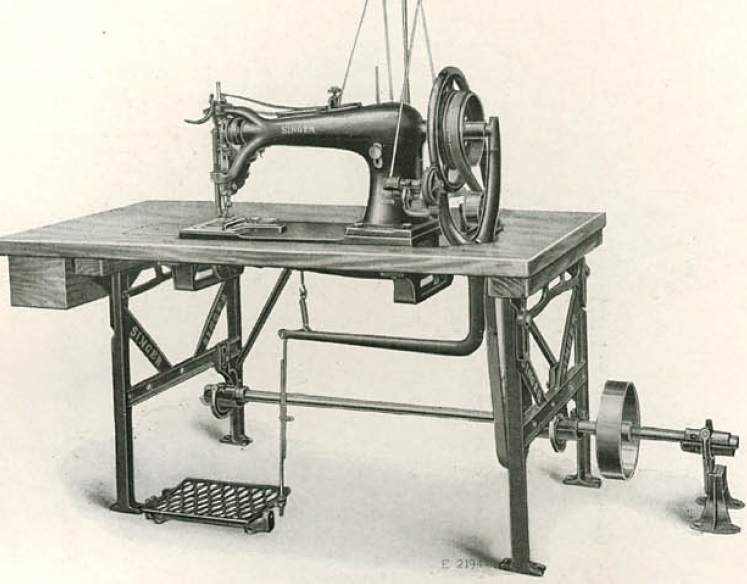

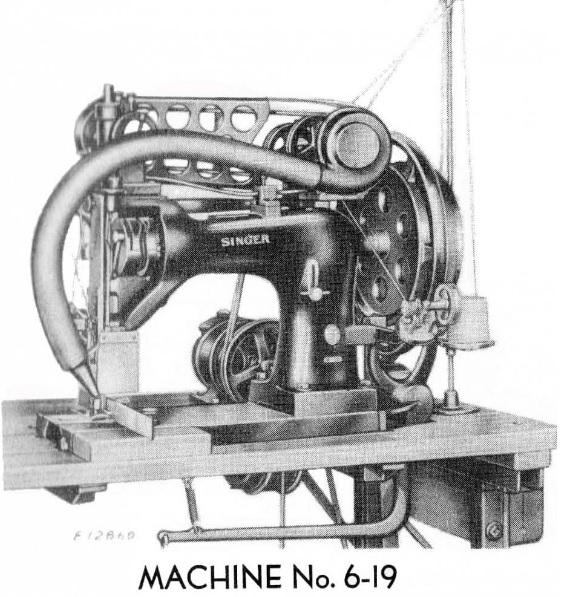

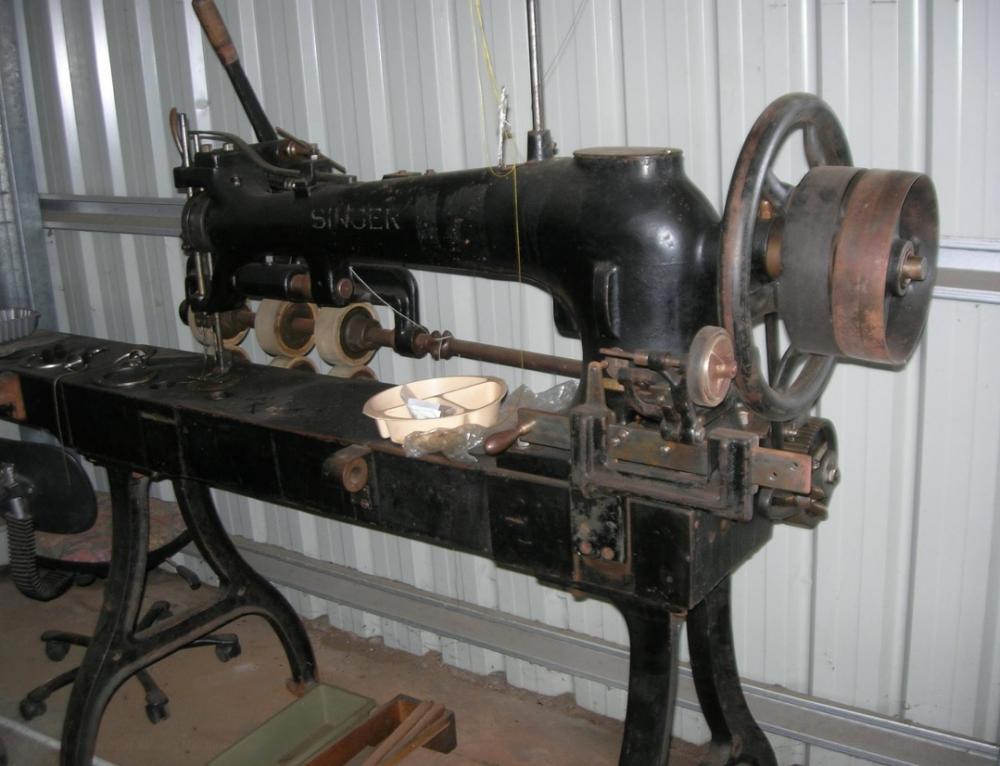

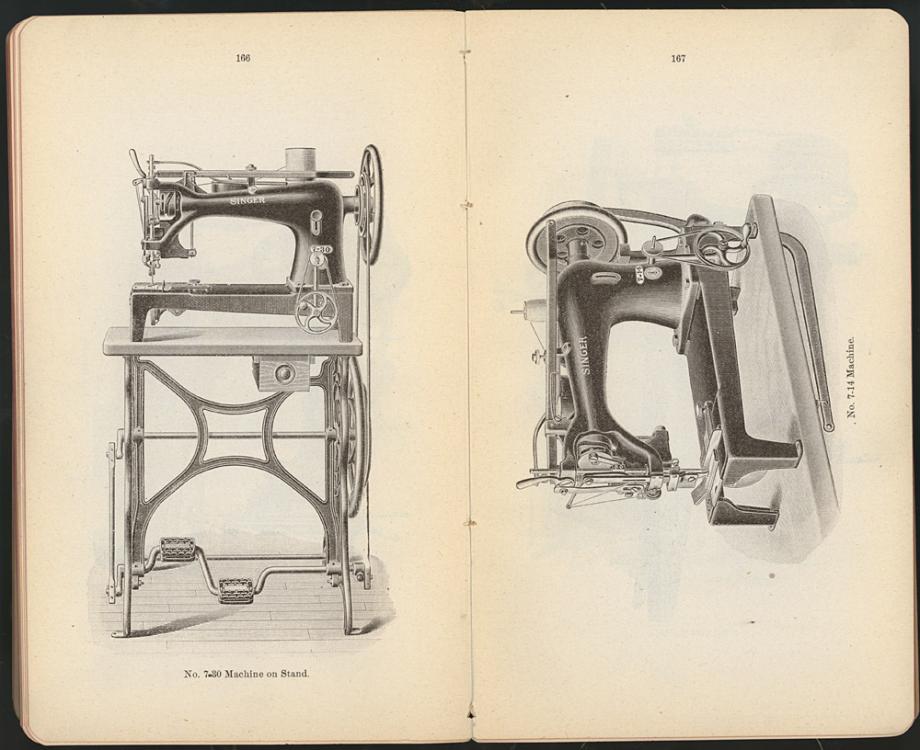

I think that motor on the side is for the drill and or air compressor separate from the machine motor and drive system. This setup is similar to the Singer Class 7-31. The hand wheel has a clutch-wheel on it and when you press the pedal the large arm engages the spinning clutch against the hand wheel to start it sewing. This clutch-wheel looks like it has been removed and they are just placing the belt directly on the hand wheel. Here is a better picture of how the machine would have looked in the power table with the clutch wheel and arm even though this is the Class 7-31 it is the same mechanism. On this type of hand-wheel it doesn't have the belt groove since they expected you to place the wide belt on the clutch-wheel. But I have run my class 7-31 with the belt directly on the wheel and it still woks. You could also swap the wheel for a 7-33 wheel that has the v-belt groove.

Back to your original question, I don't think it would be the best machine to sew leather. You probably could convert it to a class 7 needle, but still its not what the machine was intended to do, and depending on what it cost it may not be worth the conversion. If you get it for a very reasonable price (for me that number would be less than $100 USD) it may be worth the effort, otherwise I would pass and keep looking for a Class 7 machine. On the other hand if they have all the extra parts in a box then it would be of more value, since you may be able to restore it.

31

-

That looks like an interesting machine. In its current setup it appears to be missing the "drill" attachment? Plus when they say drill, I think the actually meant drill rather than needle and awl. If it was a good deal and worked I bet it could be handy, however I have found it better to leave "book-machines alone unless your actually making books.

-

Yes, it is very simple. Here is the video.

-

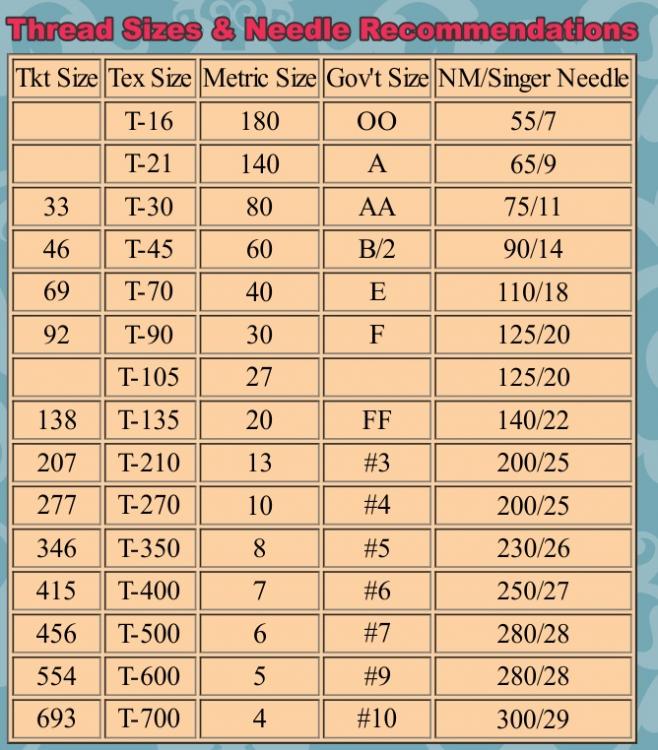

I struggled with this question for a few years and went with the CB4500. Just like you I have a Singer 111w155 that is similar to the Sailrite and it can cover the smaller weight leathers and canvas, but I wanted a machine that could do more. I run 346 thread in it and it doesn't flinch on a single stitch it runs so smooth I wish I had 2 of them. I feel if I had gone with the CB3200 with the shorter arm and less clearance I would have wished I got the CB4500. Plus with @Uwe flat-bed table it converts into an exceptional flat bed machine and I see my Singer 7-31 gathering dust. So I would recommend getting the base CB4500 with Uwe's custom flat-bed. I know it seams like a lot more money, however these machines last 100 plus years so it is worth the money.

-

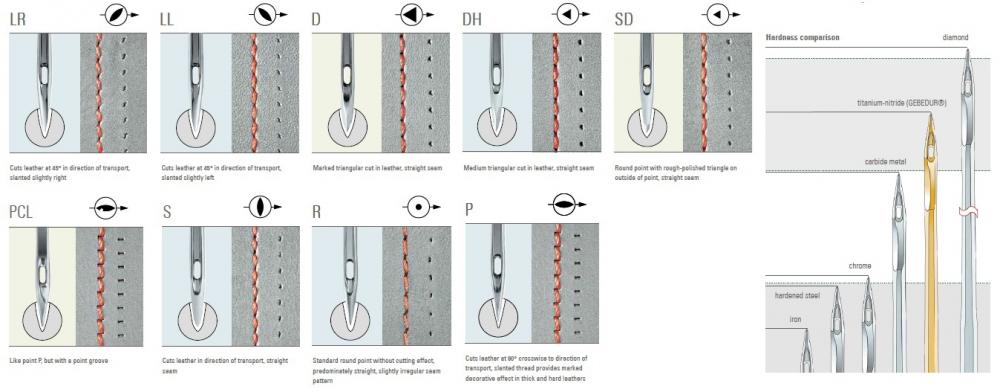

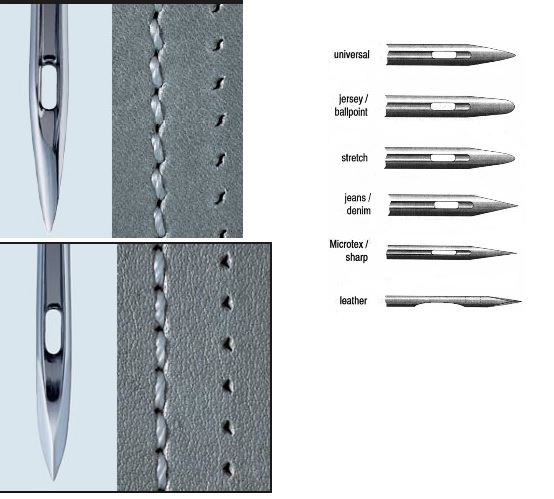

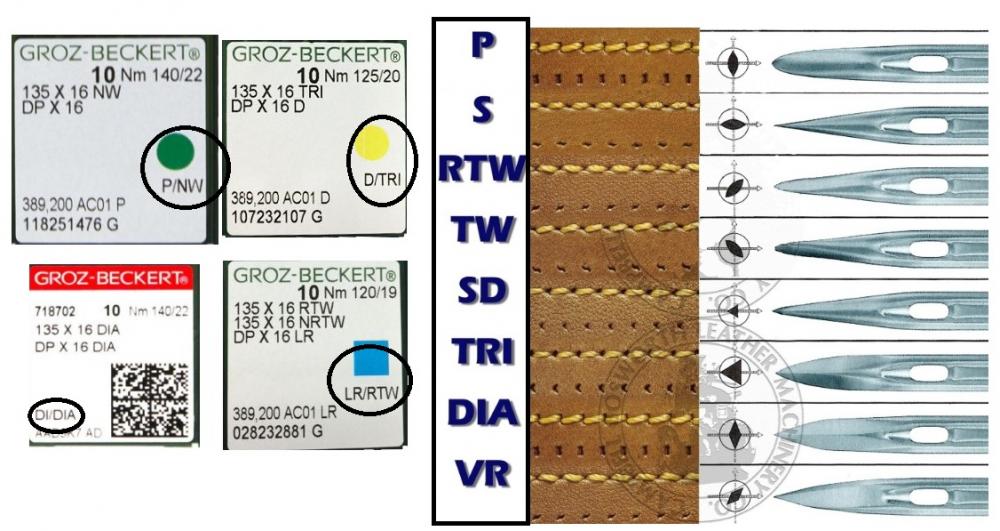

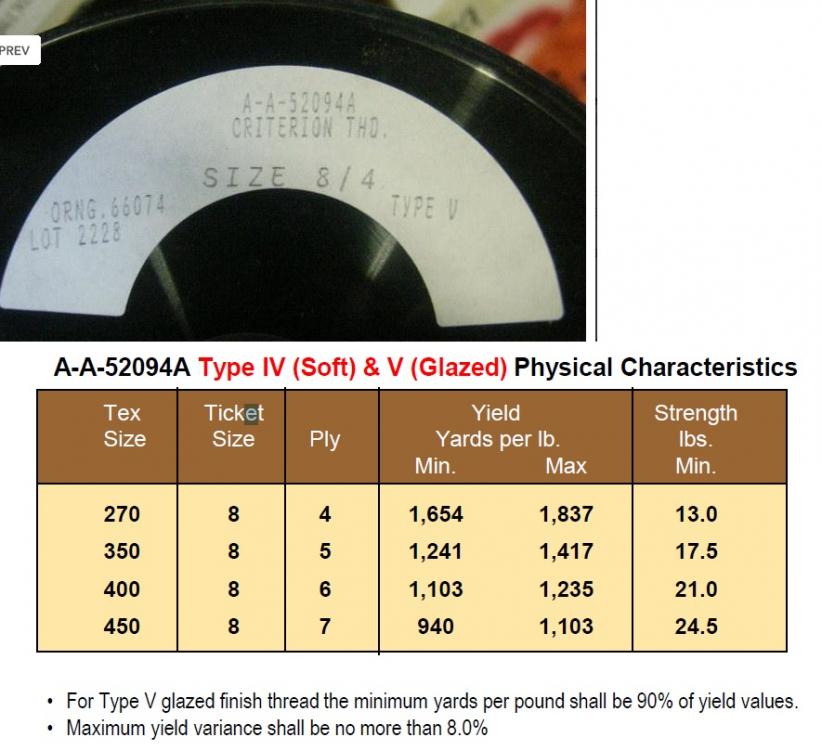

I made up a needle and thread PDF that covers some basics.

-

WOW that's great. thanks for the find.

-

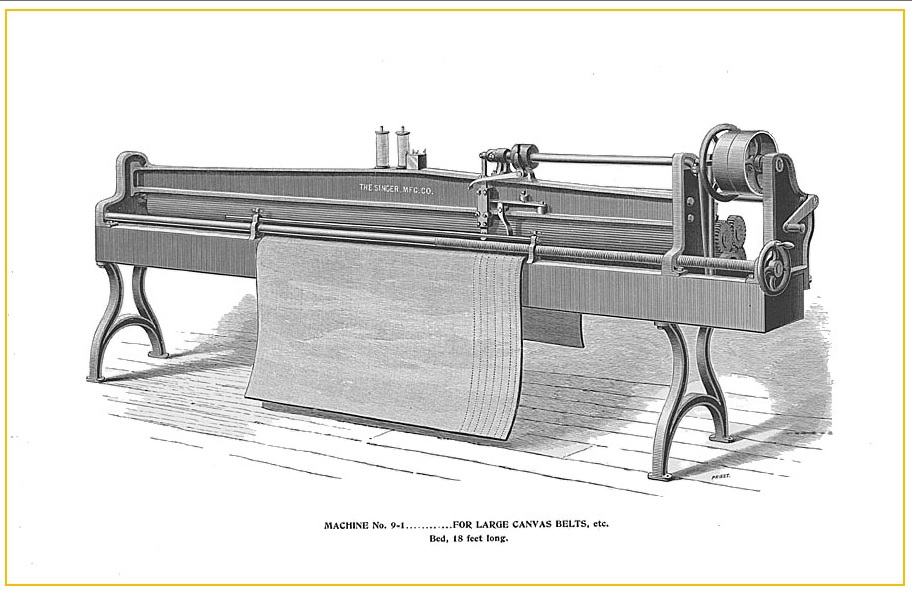

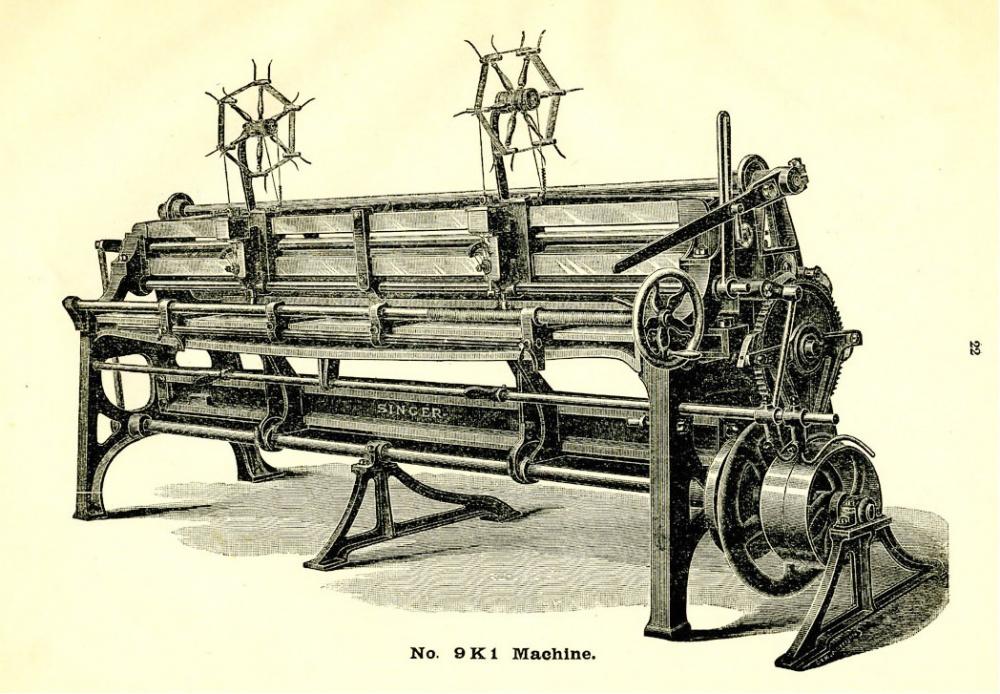

-

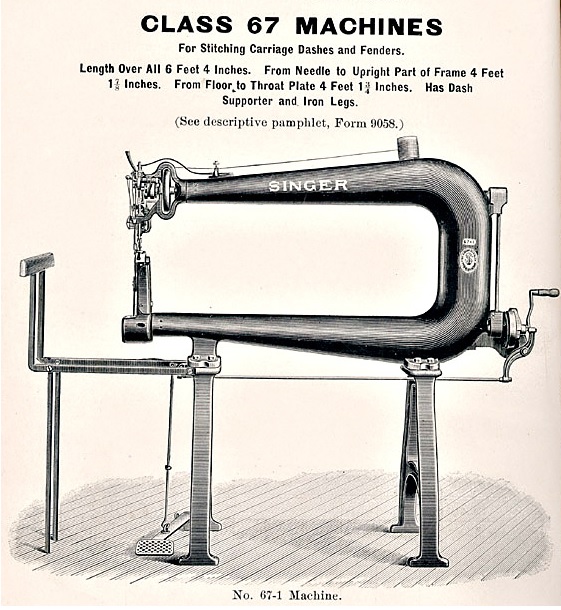

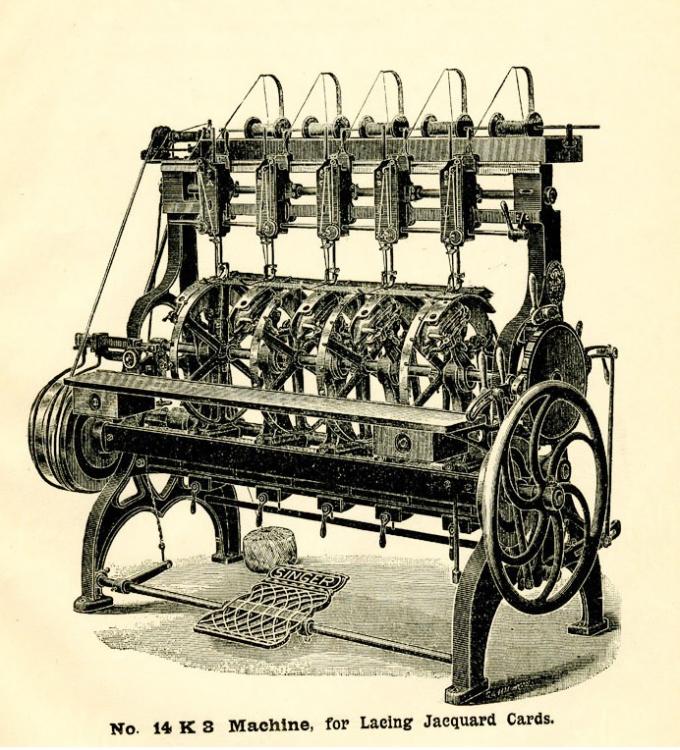

I think if you saw a 9-1 in-person it would be very impressive, but it looks like a quilting frame rather than the traditional machine shape so it lacks in its overall "wow factor" from the Singer rendering. I wonder if any survived? It would be great to see an actual photo of one. It would be also great to see a 14k8, they looked fairly complicated.

-

18 hours ago, shoepatcher said:

This is a Monster. One of the biggest machines Singer ever made. Bigger than a 6 class, 7 class , 8 class. Not as big as a 9 class which was THE largest machine Singer ever made. I would buy if I had it available 5-1and rebuild it just to have it. You will definitely need help moving it. Please get us more pics of it especially if you get it. I have an original parts list book to 5-1vto 5-5, 5-7, 5-10 to 5-11. Not the 5-9 however.

Is this a zig-zag machine?

glenn

This looks like an extended Class 7. I think the Class 8 is bigger than this? At least from looking at that picture. The largest machine is the 67-1

Class 8-8 monster>

-

Send me some pictures of what your missing, I may have them. There is a local place off University Ave called Service First Sewing, they would also be able to order parts and have bobbins and needles.

-

3 hours ago, patineto said:

I just got a 28 and will also like to learn as much as I can about it, Specially the mechanical up keep and "Tricks" to keep it in tip top shape

thanks

Ricky

I saw that machine listing for all of 5 minutes yesterday on CL since it was priced to sell. It looked like a nice machine good score!

-

That Union is a very nice machine. I'm not sure I would recommend that for your first machine. Plus if you have that kind of money to spend get the Cobra C4 or the Cowboy CB-4500 AKA juki 441 clone machine, that would be a better first machine for less money and it would be brand new.. The 441 clone can sew with heavy thread, 346, 415, plus if you really want to use wax thread you can add the wax pot. You will be able to get more project around the arm of the 441, and have a longer throat area to work with.

-

-

If your starting out you will want a servo motor and/or a speed reducer rather then the standard clutch motor. I also notice they come with the welt-foot (makes the round-rolled seams) not bad to have but you will also want to get a set of regular feet. The 111 has an internal belt and a clutch, you will want to check the condition of the internal belt and make sure its not ready to fall apart I'm sure there are other things to look out for but those are the major things I can think of.

-

It should just be just sitting on the cast iron braces that bolt on the bottom and you could lift it right out of the table once you remove the belt. That was how mine is setup. I really like that smaller table yours is in. They clean up really nice, with the open head it reminds me of an old hot-rod. I did repaint mine, why not I never plan on selling it. I was tempted to take it to the auto painters for a real paint job. I would like to get the decal set for it some day so it will look close to original.

One day I might find and original pedal treadle for it.

-

I would bet there are better machines for free-motion than this one? I suppose you could just remove the feed dog and try that?

The Consew guides are on this page.

-

If your buying it new you should expect it to be new when you get it. Even a used machine should be well packaged and free of shipping damage "Paint chips and scratches are probably normal and probably not a cause for concern" I disagree with this statement. Your going to pay a few hundred dollars for shipping so make sure its still in "new" condition when you get it. If your machine shows up with any damage there is a good chance it was not packaged or handled correctly and could have other issues beyond cosmetic. Really it should be fine and the first thing you will notice is that the fork-lift or pallet-jack ran the pickup-bars right though your package or they missed the pallet and took a chunk off the machine base. I suspect it could also get dropped off the forklift, I have seen my fair share of Nascar forklift drivers, it should be obvious that there was a mistake. Enjoy the new machine.

-

Not sure what model THOR your looking at? But all you need to do is compare the specs of the (2) machines and if they take the same needle class (say 135X17) then they will be very similar.

-

I suspect the machine will come with a clutch motor on it. I recommend getting a fresh servo motor that will give you more control over the speed and they are not hard to swap out.

-

On 10/25/2017 at 8:55 PM, Uwe said:

You can also remove the brake pad on those FamilySew style motors. Personally I strongly dislike those brakes. In my experience I was much more likely to accidentally start the motor while depressing the pedal just so while leaning in to position something. For me it's actually safer to remove the brake pad and keep the foot off the pedal as I turn the handwheel and manipulate the workpiece. This machine will stop quickly when you let go of the pedal, brake or not. It's a different story on racehorse garment machines galloping along at 3000 stitches per minute. It's also a different story on a car.

Even without brake pads the handwheel will be somewhat hard to turn due to the speed reducer pulley.

This hack needs one of your special instruction videos. Can you make one up for removing the brake pad?

Singer 401A help please

in Leather Sewing Machines

Posted

The Singer 301, 401a and 500a are decent machines, pick the 401a if you have the option. Yes they are home machines and not walking foot leather machines, but they are a the last batch of Singer machines made with metal parts. They are the first group of Singer machines to take the standard 15 needle, so you can get leather point needles at the fabric store and regular sewing thread and start to practice. The down side is, your using regular thread and needles, so you wont be sewing very thick or hard leather. If you have some time and a little more cash, look for a Singer 111 machine. They can be found from $200-$500 and are a true leather machine and a great machine to learn sewing leather on.