-

Content Count

358 -

Joined

-

Last visited

Posts posted by Yetibelle

-

-

Well what your sewing isn't that thick. Just like cars and trucks there are plenty to pick from, but sometimes a car can still be used as a truck even though that's not what is for.

There are plenty of machines both new and used that can get the job done. What will be the right machine for you is based on how you want to work. Some of the new machines come with great features for repetitive work. You can "program" the work; sew 10 inches - stop - back stich -cut thread, next piece. Some machines come with reverse and (most old machines don't). Plus you have flat-bed, cylinder arm, post bed machines.

Right now personally I like the new Techsew 3850, it looks like a great all around machine for a good price, (as far as new machines go). That may be to much machine for your projects?

Anyway a guy once told me if I have to get one machine go with the post-bed, they can do almost everything. (I still don't have one). HAHA.

As far as old and used machines, ask yourself if you want to be in the sewing machine repair business? They are great fun to work on and restore but there is a learning curve that may be frustrating, just like working on old cars.

You will also notice that most of us have more than one machine. This is because we are all crazy and obsessed, so don't worry to much about that.

-

Well - whats your budget? New or Used ect?

-

How important is that paddle spring? I don't think I have that on my machines and they sew fine? Does it make a difference I have been missing?

-

Yeah that is a great deal. Who got it?

-

If your pulling the material, or the material is pulling as corners it ever-so-slightly it bends the needle. That slight bend can cause the disturbance in the stich quality. Try the same type of sewing on lighter material like some canvas and see if it can turn corners correctly then you will know if its the material or the machine that is causing it to have the corner issue. If it still is not right on lighter material then it is probably a tension issue as it corners it get to much or to little tension and bunches-up. Also make sure your using the right needle for the right material. Sometimes the wrong needle, while it may sew, can have issues.

-

Nice find. They are a little tricky to use, but they are fun.

-

You pick the machine typically based on the type of work your producing. So is it thick heavy work, or medium to light work? You need to look at the description of the machine (or manual) and then it will give you the Needle System (type) in the specs. Some machines may use the same Needle System but the machines are setup and may be totally different for different work. The 135X17 Needle System can come in a flat bed, post bed, or cylinder arm machine. Plus flat bed, post bed, or cylinder arm machines can come in light or heavy Needle Systems, just like if you buy a truck, you want the right truck for the right job.

So if you go over to the Techsew website you can see how they divide the machines into "type of work" categories. Pick a category on the type of work you want to produce and the machine descriptions will specify the needle systems (type).

http://www.techsew.com/machinery/industrial-sewing-machines.html

So looking at the Techsew 3850 (new machine) in the specs it shows the Needle System, and the needle size. This may be to much machine for what your making, but it is an example of how to find the capabilities of the machine and the thread and needles it can handle.

Specifications:

- Needle type: 794 or 7x3

- Needle sizes: 18 to 27

- Thread sizes: 69 to 415

- Presser foot clearance: 5/8"

- Sewing capacity: 5-6oz leather up to 1/2" thickness

- Cylinder bed length: 10.5"

- Maximum stitch length: 13mm

- Maximum sewing speed: 800 SPM

- Techsew SmartServo motor: 800W, 1HP, 110V, 300 to 1800RPM speed settings, LED display, completely silent when idle and reduced noise during operation.

-

Industrial sewing needles and thread take a little effort to master. There are a few terms you need to understand to sort this out.

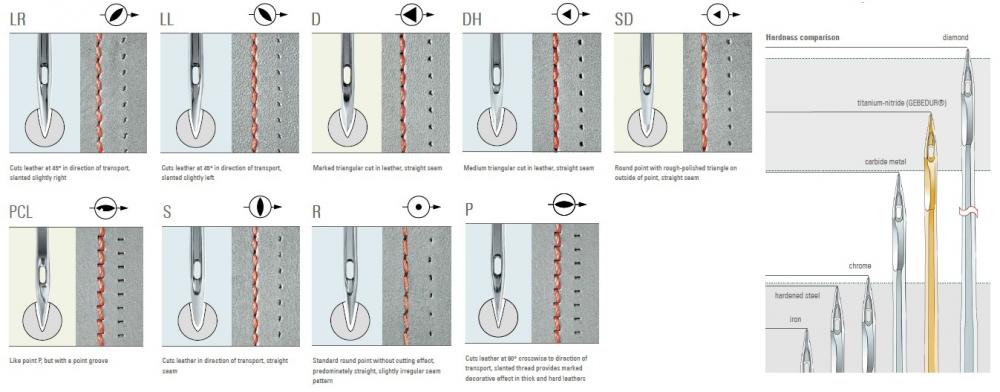

Needle System, Needle Size, Needle Point

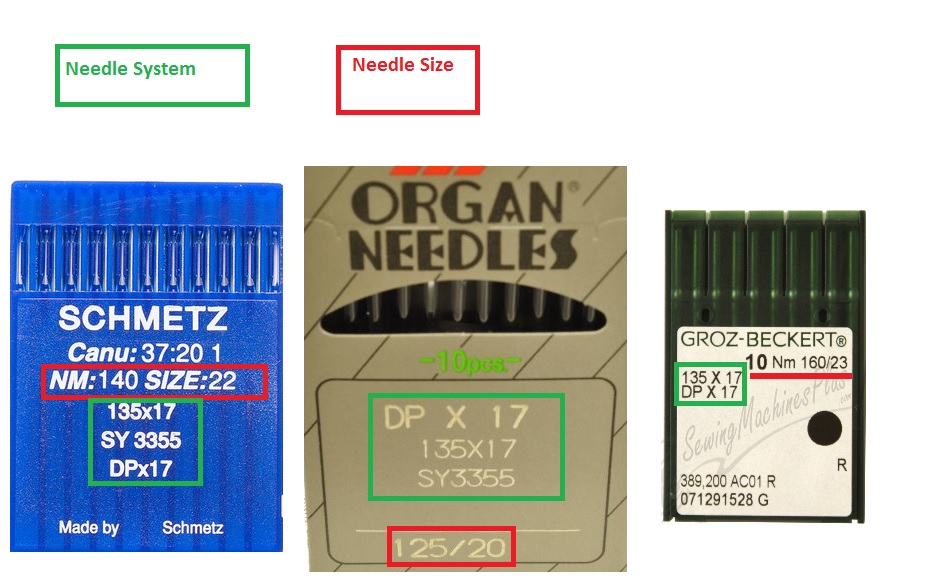

The Needle System may have a different name\ID depending on the company, country or brand of needle your looking at. So a Singer Needle System135x17, is also referred to DPx17, or SY-3355 same needle with (3) ways to identify it. The needle size refers to how thick/thin the needle is. Most needles come in a range of size 14-27, with the size 14 being a thin and the 27 much thicker. Here are (3) popular needle brands, They are the same Needle System 135X17, but they are 3 different sizes 22-20-23. The size can be in Metric (NM) and Singer size (yet another confusing variable). Canu is for Schmetz needles only as an attempt to standardize. To first get the Needle System you have to refer to the specific machine manual. Then you pick the size and point depending on the item your sewing and the thread your sewing with.

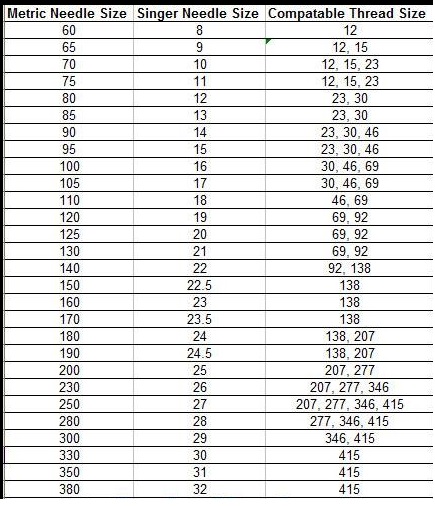

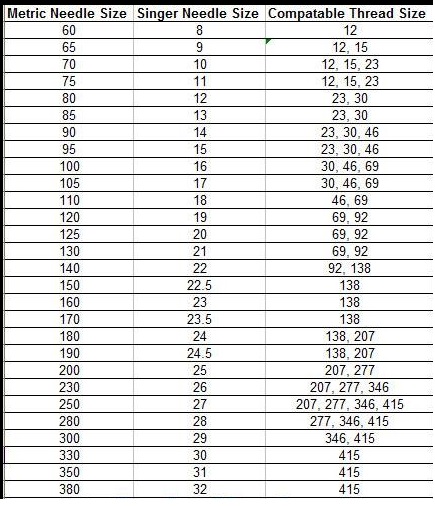

Here is the chart that converts Metric to Singer size and the recommended thread your thinking of using with that size. This is just for Needle Size you still need to pick the Needle System first. Thread comes in TEX (thick/thin) so if you want to use thread size 207 the chart below recommends a size 24 (180NM) needle, in this case for Needle System 135X7

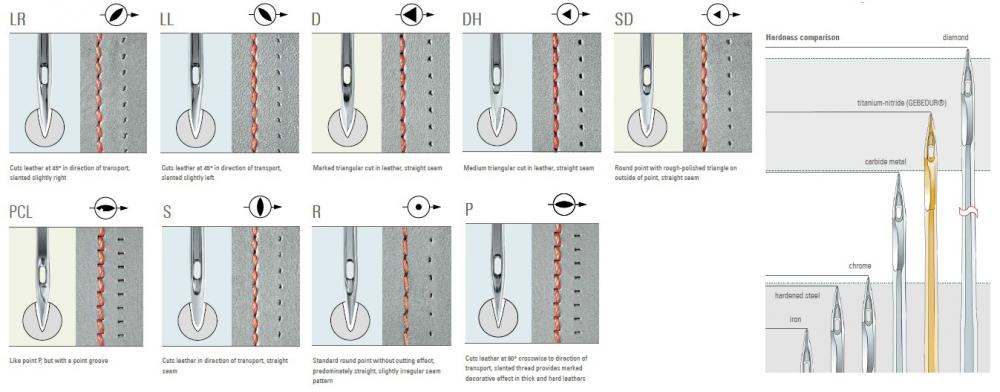

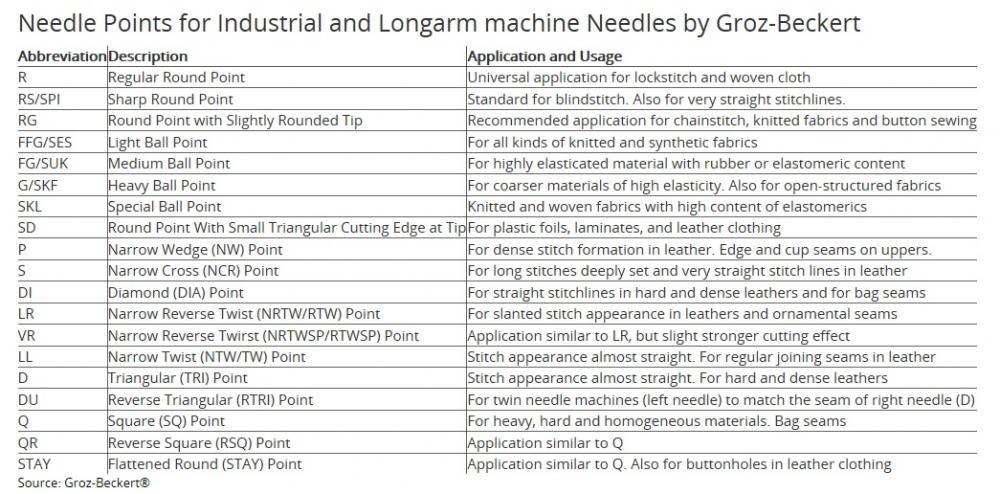

Then you also need to pick the right needle point for the type of sewing your doing. Here is the point chart.

-

The Pfaff is a post bed machine - the Adler is a flat bed. If you can only get one machine you should be looking for a post machine like the Pfaff in single or double needle, it will be a better all around machine than the flat bed for making shoes. Something more like the Techsew 860

-

The machine in the picture looks a little beat up, if it was a similar machine in a Singer, it would not be an issue. The Adler machines can be tricky to work on and the parts are harder to find and more expensive. If it was really clean and in good working order, they are awesome. However when you say "really thick material" this is machine is more a medium weight machine.

-

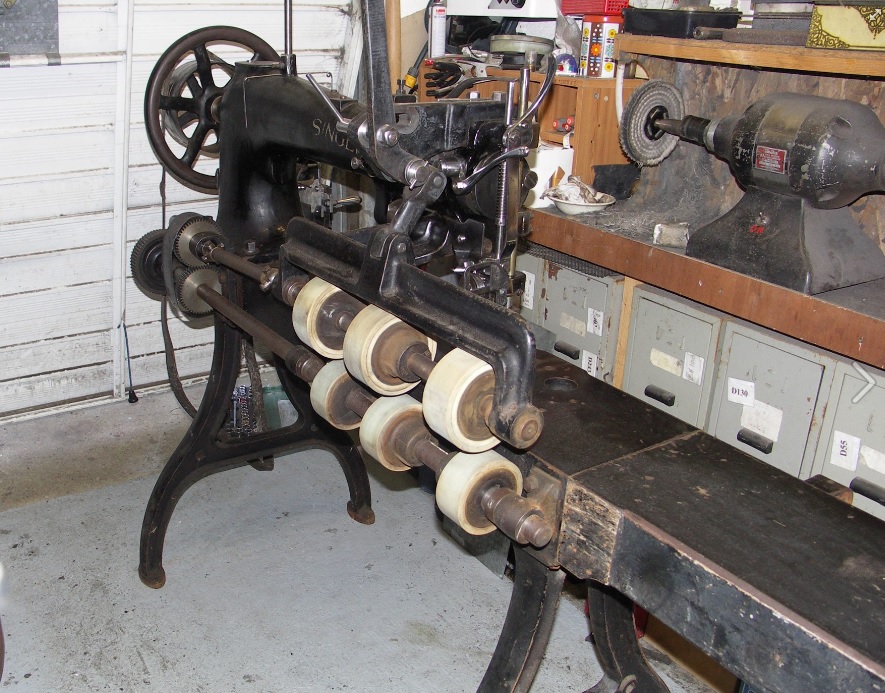

Here are the guides I found. Not sure if you have these already. I am going to restore my 20-2 in a month or so, but its made with Singer 7 parts.

https://drive.google.com/file/d/0B8SsIFb6Bqz7NmJxM0psTW9rbXM/view?usp=sharing

https://drive.google.com/file/d/0B8SsIFb6Bqz7SXAwNHNBX0lZOHM/view?usp=sharing

-

Just thought I would pass this along. I had a crack in the needle bar of my 111W155 for a while, so last night I decided to replace the needle bar. I have been putting it off since the machine runs so well I didn't want to disrupt the harmony I figured that you would just have to remove the hole feed dog (and maybe hook) assembly, then loosen a few screws and the needle bar would slide out the bottom. That is not the case however so I will try and describe it best I can. First remove the needle and the feet from the machine. You will need a good amount of light to see all this this since most of the work is lining up parts that are behind other parts that you can't see unless you have a flashlight on them.

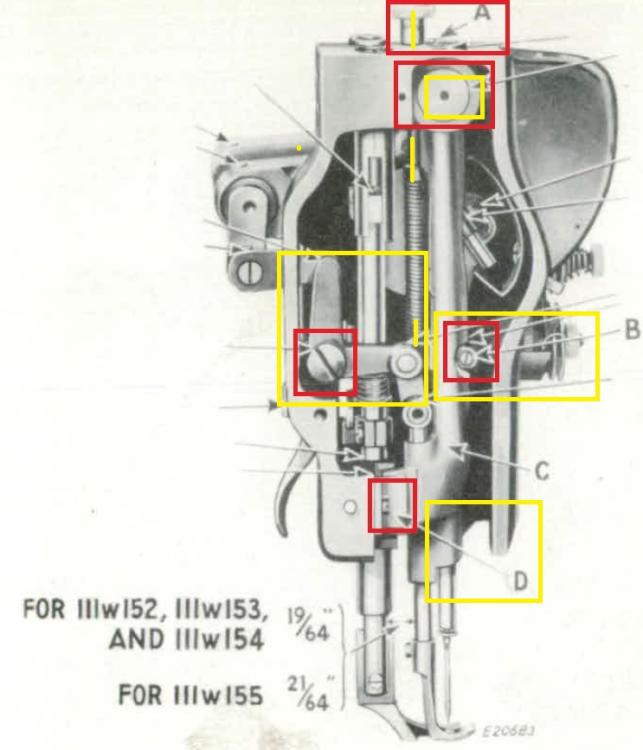

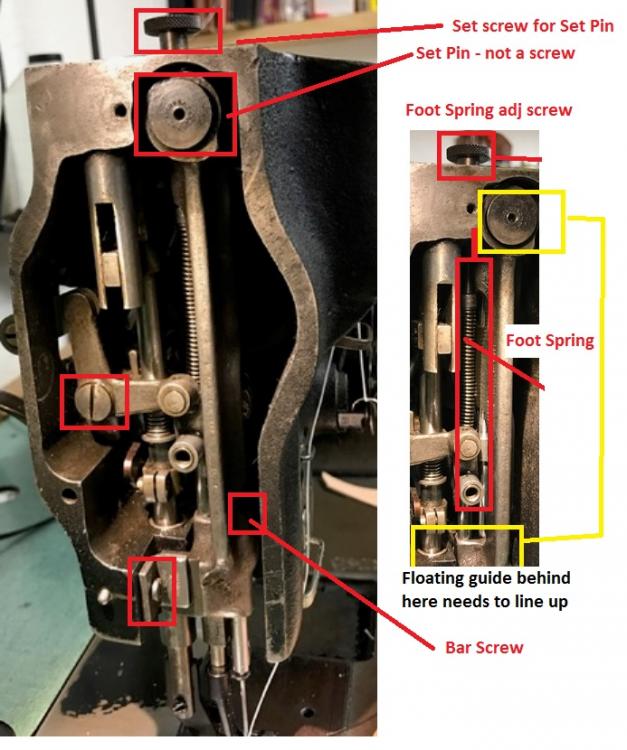

The Parts in RED are what you remove, the parts in YELLOW are what you need to line up correctly when putting it back on.

Once you have the head door open there are a few obvious screws. The needle bar set-screw lines up so you can adjust it (B) in pic, as it sits behind part 240248 that holds both the needle bar and the little foot bar assembly and tension. You can loosen this screw (B). Now starting at the top there is a set-screw (A) and the tension screw next to (A) - remove them. Then remove the linkage screw on the left middle across from (B), and then the angle bracket screw on the bottom (D). There is a window behind the large set-pin below you can pop it from the back with a screw driver. The whole assembly will slowly pull forward off the cam-link (B) and you will have the needle bar and the little foot assembly off the machine.

Now you can remove the bad needle bar and put in the new one. The trick to getting it all back together is the little foot spring tension bar needs to line up with the top hole (at the same time) you line up the Pin (B) into the cam arm linkage. Put the foot tension screw back in a little ways so when the tension pin and spring pop back in they will rest against it. There is a floating guide behind (D) - also marked in yellow below, that needs to line up in the track. Once you have them all in-line the linkage will slide back into place. You have to line up 4 separate parts at almost the same time to get it back into place. The little-foot tension pin and spring - top -, the needle-cam arm (B) - middle -, the floating guide behind (D) - bottom - and the linkage bracket (middle -left). Once it is all back in place you can put all the screws back and the feet back on. I got lucky and set the needle height correctly the first time so I didn't mess up the hook timing.

-

-

16 hours ago, h1clm04 said:I know that there is a lot of information already out there for beginners to choose a machine. However, I thought someone may be able to offer some suggestions given my particular scenario:

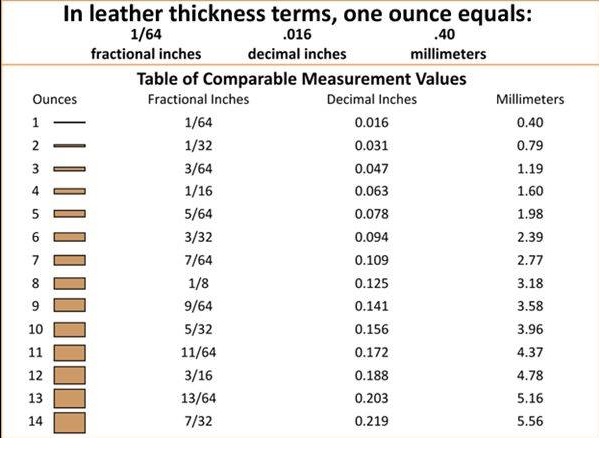

I generally work with 3-5 ounce chrome tanned. So, in most cases the maximum thickness I would ever expect to work with would be 10 ounce together.

Here is a list of some machines I found locally:

Bernina Record 830 - $450

Domestic 153

Singer 500A - $50

Singer 401A - $250

Singer 15-91

Pfaff 34-6/2bs

Pfaff 360

Of course, I understand that condition plays a big role here. I am hoping to stay in the $500 range. I don't expect to run this machine heavily or often. And, as mentioned I will probably max out at 8-10 ounce chrome tanned. I am hoping somebody can provide some recommendations or insights with all of this information in mind.

If you want to start with an old "home" machine rather than a leather machine you will be disappointed, yes they can sew leather and canvas and do an ok job but not 10OZ, that is to much. I would say look for a Singer 111 (or comparable) or a Singer 29 treadle machine. These machines are typically priced under $500 and easy to use and maintain.

Bernina Record 830 - $450 -----NO

Domestic 153 -------NO

Singer 500A - $50 ----- not a bad machine for $50 bucks if its not locked up and has the cams with it wont do 10OZ of leather, but has great default stiches

Singer 401A - $250 ----- Also good machine but $250 is to much - wont do 10OZ leather

Singer 15-91 - basic machine will sew like a tank - still wont do 10OZ

Pfaff 34-6/2bs --starting to get there but recommend a speed reducer and or servo motor extra $150 for that.

Pfaff 360 - Also Nice machine wont sew 10OZ

-

-

This guy has everything, plus some stuff I have never seen before - worth a shot. I have just looked at his pictures never contacted him.

Steve's Industrial Leather Sewing Machines 126 Booloongie Road,, 4670 Gooburrum, Australia +61 419 393 750

-

NICE work!

-

How about the NEW TechSew 3850. All this in the base package, just under $1700 looks like a great deal?

•Powerful compound walking foot feeding mechanism

•Sews from 5-6oz leather up to 1/2" thick

•10.5" cylinder arm

•Extra large capacity bobbin

•Reverse feed for reinforcing stitches

•Includes chrome plated double-toe foot & center groover foot - will not leave footprints on leather

•Equipped with the 1HP 800W Techsew SmartServo motor and speed reducer to sew at slow & controlled speeds - great for novice, intermediate and professional sewers

•Large heavy duty flywheel

•Uses the same needles, bobbins and presser feet as the Techsew 4100, 5100 series

•Includes fully assembled reinforced U-table, bobbin winder, lamp, threadstand, accessories (needles & bobbins), tools, instruction manual

•Includes Limited Lifetime Warranty and FREE technical support for the life of your machine

•Machine comes pre-threaded, oiled, adjusted and READY TO SEW

-

I suspect you have the room to mount it like this?

-

The speed reducer is just a pulley that mounts in between the motor pully and the machine. So you will need that and a second belt.

http://www.techsew.com/parts-supplies/sewing-accessories/speed-reducer.html

-

Ahh the tricky Servo motor question - how slow can you go? Well I can't comment on the "digital part", but the Sew Green 550 servo motor I use has a dial on it that drops the speed down or up. If you want the one-stitch-at-a-time control, you will want to install a speed reducer along with the servo motor. this will let you bring the machine to a crawl. You can get really slow with the servo alone, but it takes a little practice with the foot. There are digital systems that I assume replace the knob with a digital number. I have been happy with this motor and no speed reducer.

-

On 3/7/2017 at 6:13 PM, JimTimber said:We'll "never see another one like it!" Good thing we won't need to - that one'll be there waiting for us if we ever want to have another look.

Ok - I went to The Vault and found another one, so now we have 2 for the Museum . I don't think many original owners of the these machines ever used them that much. I bet it was a status symbol in the parlor. I paid 18 gazillion dollars for it at a fancy auction.... ok $25 from a yard sale.... What else we got for the Museum?

-

Personally -

I would not recommend a Sailrite. Did you read Wiz's post in the sewing forum on "The Type Of Sewing Machine You Need To Sew Leather" its a great place to start. That being said - here are the basic questions to ask yourself:

How many hours are you sewing, hobby or full time? How much $$ do you want to spend? How much time spent fixing sewing machines?

I am sure there are a lot more questions to ask but that is a good start. If you go out to CL you will see a number of machines that look big and sew anything and may be in your budget. However they may need constant care-and-feeding, my not be leather machines, and you will be in the sewing machine repair business rather than the sewing leather book business. However if your handy with some tools you can save a lot of money and sometimes get lucky with a machine that is in good order. Now if you are sewing full time and want to make it more than a hobby then you need a newer machine that will be reliable.

Personally I am in the sewing machine repair category - so I like the old Singer machines.

-

5 minutes ago, dikman said:Thanks CD. One problem I have is that the handwheel is too small. None of my other handwheels will fit, as they have a 1/2" bore and the shaft on this machine is actually slightly larger than 1/2". I have a few options - bore out one of the handwheels to fit this shaft (but then it wouldn't fit anything else), find a suitable steel disc and turn a handwheel to bolt onto the existing wheel, likewise with a piece of aluminium, cast an aluminium handwheel or turn one from wood and bolt it to the pulley. I'm going to have to give this some thought.

I've also come to the conclusion that this setup will only be suitable for cloth and/or light garment leather - no big deal really.

(I just saw an old White treadle machine for sale for $100. It has a bigger drive wheel and would be nice to play with, but I'm not game to say anything to my wife!!!).

Singer 132K SV 11 -> a 132K6 variant?

in Leather Sewing Machines

Posted · Report reply

Did the Jawa's stop by and unload them from the Sandcrawler like in Star Wars?