-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by iron1951

-

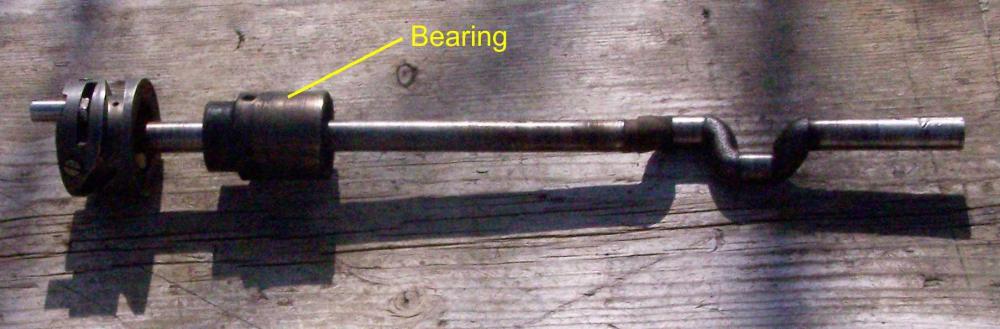

Constabulary, I hear you and will go that route the next time. But I had to try. Good learning experience. Never going to do it again. I think that the bearing is pressed in with a special tool and is not meant to be removed. The driving shaft is not stout enough to use to remove the bearing without damaging the shaft. I will remember this for future projects.

-

I was taking my 21W30 apart in order to strip and paint it. First time I have tried this. The last thing to remove was the driving shaft in the head. Trying to press out the bearing I bent the driving shaft. I finally got the bearing out but I had to use lot of heat and the press. Is there some trick to get this bearing out? This is the bearing next to the thread take up lever.

-

I am curious, does it have reverse?

-

-

I am negotiating the purchase of a 52W22. One of the machines is missing the tensioner assembly. Any idea of where one can be found? Would another brand work? Thanks iron1951

-

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

Eastwood advertises Hi-temp Lab metal. Says it is great for filling before powder coating. -

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

I will definitely show some before and aft pics. Its going to be a while. Don't even own a gun yet. I'm not sure which machine I will try it on. I want to get them sewing properly before I tear them down. -

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

butchlambert, I am no expert on powder coating because I have never done it before. I think I will be getting into it. I am going to buy my gun from the Eastwood corporation because I like the two voltage system. If you follow this link, they will explain how to powder coat glass. https://garage.eastwood.com/eastwood-chatter/can-you-powder-coat-glass/ -

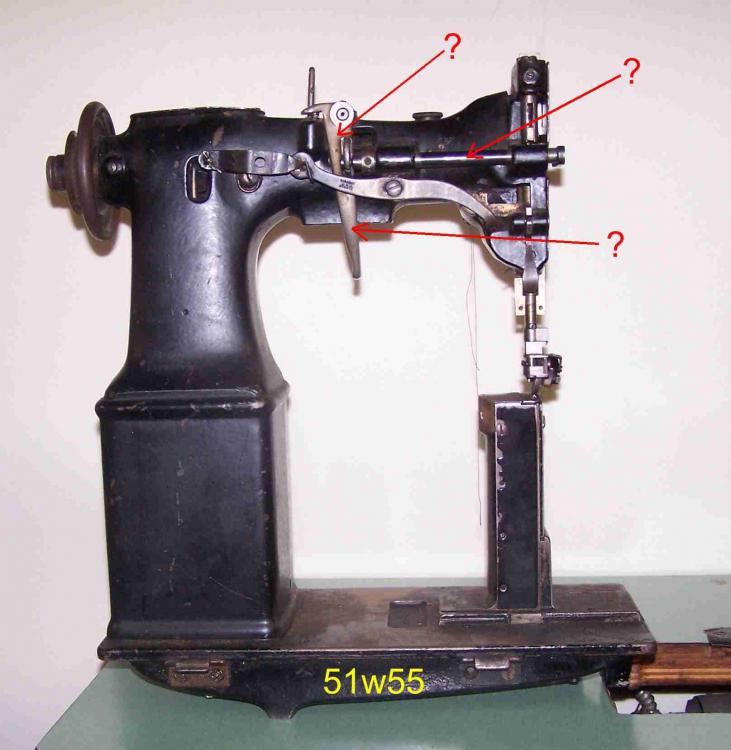

Does anyone know what these parts do on the 51w55. They are not there on my 51w44. I have no idea. Thanks iron1951.

-

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

Amuckart, any chance of pictures? I would love to see the final result. -

Bert51, I really cannot tell you how the polyurethane belts work under load as I don't sew, just repair/restore. The belts are "sticky" and seem to grip well. I don't think they need to run tight. They have a bit of stretch to them. It seem that when the belt is running, the drive side tighten up and the coast side slackens a bit which I think adds to the grip factor. I put the belt on and off without having to adjust the tension or tilt the machine. I bought mine through Amazon.ca, 6mmx10m for under $25can. I can't believe how easy they are to join. Hope this helps. Iron

-

I have decided to go with the 6mm (1/4 inch) polyurethane round belting (orange). Cut it to length, heat up the ends and join. This video shows how I joined the ends https://www.youtube.com/watch?v=KMqMYwPw2Cc&feature=youtu.be

-

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

Fredk, I did not know that about cast iron. So putting it in the oven to dry it out will only enhance the sticking power of the powder. They use heat to powder coat glass (from what I read). Chrisash, the oven I am going to use is just a regular oven I found on the side of the road. So the amount of electricity used would probably be not much more than the amount needed to bake a pie. Haven't done any powder coating yet, don't even own the electrostatic gun, but I believe the part only needs to be in the oven for about a half hour after the oven has been preheated. Someone correct me please if I am wrong. Anthony -

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

Frodo and Evo160k, thanks for your replies. I have thought about Japanning, it gives a beautiful finish, but I like the idea of spraying the finish. I never seem to have any luck with brushes. Does anyone have a picture of a sewing machine that has been powder coated? -

Powder Coating - has anyone tried it?

iron1951 replied to iron1951's topic in Leather Sewing Machines

Powder coating sounds what I am looking for. Plus it can be applied in "not so good" weather. I am concerned about the thickness factor. Others please chime in. Powder coating could be what I am looking for in the winter time. -

I am contemplating stripping and powder coating an "old iron" machine as a method of restoration. Has anyone tried it on a machine body? Were you pleased with the results? Would you recommend powder coating vs painting? Can you put decals on powder coat and then clear coat it? I already have an oven. Want to purchase a gun. I would like to hear some opinions. Thanks

-

Figured it out!! My hook timing was off. I was timing the hook as the needle descended, at it lowest point. What I did not do was wait until the needle plate carrier frame (208549) moved to the rear and the needle just started to ascend. When the hook is set just above the eye of the needle here (needle plate carrier frame at rear), there is no interference. There is even room to lower the needle bar which I had to do. So it looks like I do not need a new hook. Thank you all for your help and letting me talk this out with you.

-

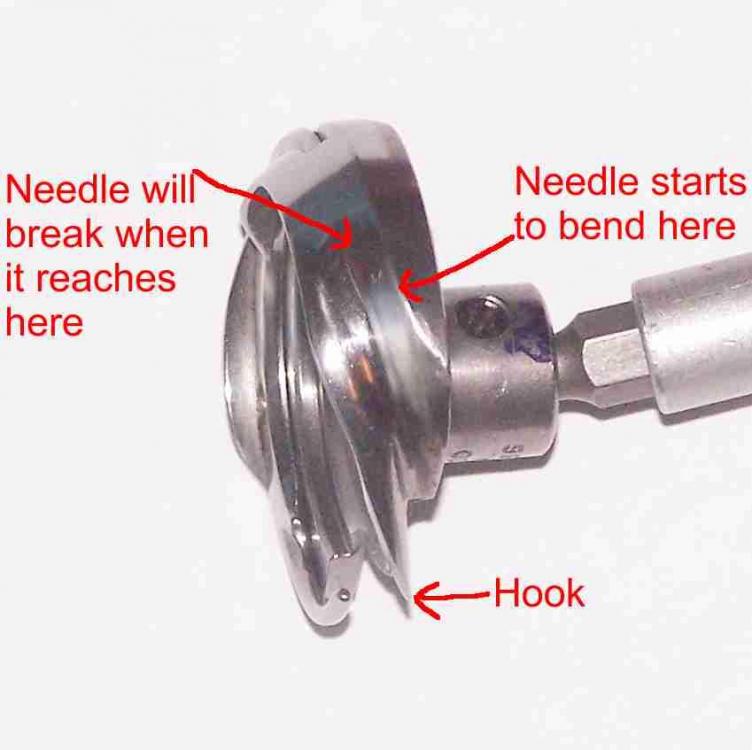

Here are some more pics of my hook. Maybe my timing if off? As the needle starts to rise the point of the hook is above the eye. BUT this is unison feed, so as I continue to rotate the hand wheel, the needle bar moves rearward, the needle interferes with the hook assembly before it has a chance to rise out of the way. (see pics).

-

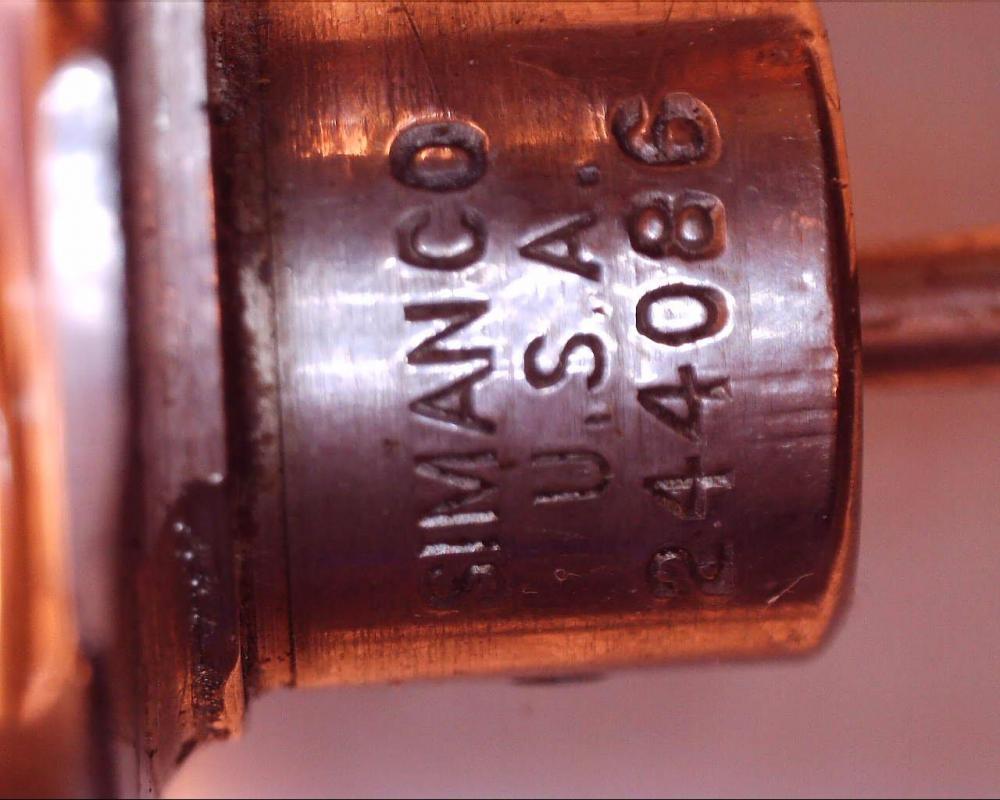

Constabulary, my needle is 36.16 mm long, shank to tip. Nice pics btw. Do you have a camera stand? I tried using my magnifier (244086 pic). Okay for really small stuff.

-

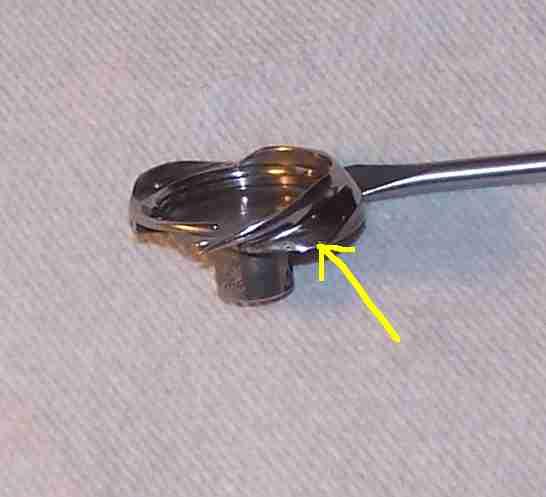

Just after the hook (yellow arrow) that is where the needle is being "pushed". Is it possible that my timing is off?? I line the hook up above the top of the eye as the needle just begins to rise. My needle bar does not have any marks. As the needle rises, it moves towards the back of the machine and that is when the needle hits where the yellow arrow points. As I continue to rotate the hand wheel, the needle continues to be directed towards the left. The hook assembly is pushing on the side of the needle. The needle is not bending towards me but bending towards the left.

-

-

The hook that is giving me a hard time, the one that came with the machine, is #244086. After the point of the hook passes the needle as the needle is rising, that is when the needle hits the rest of the hook assembly. It actually bends the needle quite a bit. I would say the needle bar is adjusted correctly because the point of the hook reaches the needle just above the needle eye. The hook does not touch the needle. about a 10 thou clearance. Does anyone know what machine hook 244086 would fit. Just curious. Wiz, thanks, I already have that parts manual. If I read the manual correctly, I should have hook 247789 Constabulary, do you know the part number of the Singer hook you replaced? Thanks

-

I have been working on getting my 108w20 into sewing mode before I try some sort of restore. I was working on the timing and I broke a needle (no confidence it was the correct needle anyways). So I bought some Schmetz 135x1 needles. Now turning the hand wheel slowly I still have interference between the needle and the hook. So as you (and I now) probably have figured out is that the hook is wrong. The hook that I am looking for is 247789 and the hook that is in the machine is 244086. I can't seem to find a 247789 on the net. Any ideas? Has anyone had any experience in modifying the hook? Its not the point that is giving me the problem, but the "ramp" that follows the hook.

-

Northmount and mikesc, thanks for the pointers. The distracting background is going to be the problem. Where I take the picture is where I work on the machine. I will see what I can do. But that machine is heavy to move around. I will see what I can do for close ups too. I really enjoy working on these machines. I am so impressed on the machining, the close tolerances, the timing. You know what I mean. The worse shape the machine is, the more I like it. Thank you for your words of wisdom.

-

Glad to hear this mikesc. I was not sure if anyone was interested. Right now I am awaiting needles for my 108w20 so I was looking for an interim project. I will try to include pics as I go. First time posting pics of my projects. I don't have a cell phone so I use an "old" digital camera. Any suggestions to improve my pics would be welcome. Thanks.