-

Posts

150 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by ChiefFilipino

-

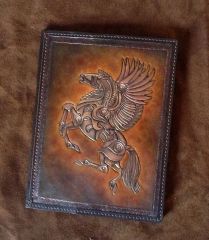

pegasus document folder

ChiefFilipino commented on leatheroo's gallery image in Our Leatherwork Galleries

-

Dying & Wet Forming Knife Sheath

ChiefFilipino replied to ChiefFilipino's topic in How Do I Do That?

Thanks Mike! -

Wet Form Knife Sheath & Welt Question

ChiefFilipino replied to ChiefFilipino's topic in How Do I Do That?

I have seen some of the videos on YouTube and saw a bunch of different methods, but didn't know which ones were quality (some were obviously not). I haven't braved the cost of higher quality leather yet though seeing as how I am just starting off. I can't justify the cost as of yet. I can't even tell quality leather from not so good leather except maybe by price, is there a tutorial on determining leather quality? -

Dying & Wet Forming Knife Sheath

ChiefFilipino replied to ChiefFilipino's topic in How Do I Do That?

Thanks! I haven't tried the layering process for the sheath yet. I really like the wet form/molding or folding process whatever it is called. I want to play with this style for awhile and then try my hand at the layer process like the tutorial you shared. Thank you! -

Wet Form Knife Sheath & Welt Question

ChiefFilipino replied to ChiefFilipino's topic in How Do I Do That?

Does anyone know of a wet form sheath tutorial, pdf, video, website that goes into great detail? There are some that I've found but it seems like I have more questions than answers. Thanks -

Cross Draw Sheath

ChiefFilipino replied to thefanninator's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nicely done, the stitching is impressive on the front. -

My First Sheath

ChiefFilipino replied to 8ball's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nicely done! -

New Sheath For My Khukuri

ChiefFilipino replied to Otto6294's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice job. Does the sheath hang from the belt? That's what I am assuming the key fob type attachment is at the top. Am I correct? -

First Knife Sheath

ChiefFilipino replied to Mark Peters's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks good! -

Dying & Wet Forming Knife Sheath

ChiefFilipino replied to ChiefFilipino's topic in How Do I Do That?

What about the thickness of the welt is what I meant? For example from the stitching to the blade itself should there be a gap? Or should I basically cut a silhouette of the blade out and have everything snug as a bug? -

From the album: Sheaths

After adding the second strap all is good! -

From the album: Sheaths

Single strap wasn't holding the sheath onto the belt well, it was sliding all over the place. -

From the album: Sheaths

-

From the album: Sheaths

-

From the album: Sheaths

-

From the album: Sheaths

-

From the album: Sheaths

-

From the album: Sheaths

-

From the album: Sheaths

-

From the album: Sheaths

Horizontal draw, veg tan, nylon wax thread, buffalo bone handled knife stained with blueberries -

Dying & Wet Forming Knife Sheath

ChiefFilipino replied to ChiefFilipino's topic in How Do I Do That?

Those are beautiful Red Cent! When I add that inch behind the finger guard and the leather collapses, won't I be smooshing the leather when I re-sheath the knife? With this one the guard was ramming into the leather and it would collapse together closing off the hole. -

I really like friction/tension hold sheaths and I am working on one right now (a horizontal draw) when a question popped in my head: can I dye the leather first (I like oil dyes) while the pieces are apart, then wet form the sheath around the knife after that? For the knife sheath I'm working on now I wet formed it first then dyed it but I was just curious if I could go the other way around. A second question issue came up with this project, it is a small knife with a finger guard. I have the sheath going up like a quarter of the handle and as I was wet forming the sheath the leather dried and the opening shrank a little. I could pull it out just fine but when I would go to put it back in I was mashing the leather. I cut a hole along the top a little to make it so I could put the knife back in without mashing the leather. The question is: when I am wet forming a sheath how do I accommodate the finger guard but still maintain the tension/friction necessary to hold in the blade? Third question: how large do I need to make the welt? The welt I have on this one is about 1/4 inch but the blade moves around a lot in the sheath. Do I need to cut the welt in the shape of the blade? Thank you!