-

Posts

1,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chief31794

-

-

Yep, they came through this time. Good looking work, nice job. Ken

-

If you're looking for instructional material the I would get the three volumes of Al Stohlman's , The Art of Making Leather Cases. These are somewhat dated but the general principles of leather goods construction and layout are still valid and a good place to start. Welcome to the dark side, this hobby is addictive and will absolutely consume you so either leave streaks in the parking lot getting away while you can or strap in and hold on it's a wild ride. Leather is fun!!! Ken

-

Where To Start With A Limited Budget?

Chief31794 replied to BurnTheBarrels's topic in Getting Started

I'll take a shot at these: Vegetable Tanned Leather, about 5 oz (5/64" thick), but this is up to you could go heavier or lighter depending on your preference. You will need at least 1 needle for the lacing, most use the double prong needle shown below The rivet setter and snap setter have two different surfaces, however you can get everything you need in one set for ~$20.00, I've attached a picture of them as well Your choice on lace, I would use 3/32" leather lace. Your choice on finishing, use leather dye to achieve the color you want, let it dry then finish with resolene, super sheen, tankote (my favorite), etc. Hope this helps, if you have a local Tandy store go there and they will assist you, if not, checkout their site http://www.tandyleatherfactory.com/en-usd/home/home.aspx?navlocation=top they have many instructional videos (Free) that will show you how to lace, how to set snaps and rivets, dying finishing, etc. Hope this helps, good luck, Ken -

Sounds like you might be getting some transfer from the black dye, I would let it dry thouroughly (24 hours if possible) before putting on a finish and then let the finish dry another 12-24 hours. If you put finish on before the leather is completely dry it will seal the surface and the dye can still be moist underneath, then when you sew you get dye transfer onto the thread. Just my $.02 worth. Ken

-

Welcome to the wonderful world of Leathercraft. There is a lot of good information, tips and techniques out here. Ken

-

X2 on Ohio Travel Bag, they are great to deal with and have excellent quality hardware and a wide variety of it. Ken

-

I usually use deglazer just before I dye, but before that I may also clean the leather with Oxalyic (Sp?) Acid to remove smudges from hand oils etc. As to your question about making Fiebings not so extreme, you can cut it with Denatured Alcohol. I have cut light brown by as much as 10:1 10 parts alcohol to 1 Part Dye, but normally no more than 5:1, I keep small sealable jars for mixing the dye and mark them with the concentration and dye color. You might try that and test on scrap for results. Fiebings dye should be allowed to dye for several hours up to 24 if possible before applying resolene, super sheen, tan kote, etc. That's just my opinion, spirit dyes seem to go on very strong and then balance out and lighten after several hours. If you seal before they are totally dry you will get unpredictable results and yes you might get lots of dye coming off. This is just what I do, there are lots of folks out here with a lot more expertise than I on dyeing and finishing. The main thing is don't rush anything to do with the dying and finishing of your projects. Ken

-

-

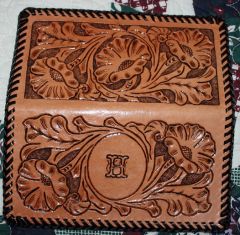

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

From the album: Work Examples

-

I'll send a PM next time I go up to see the Grandchildren. Thanks, Ken

-

Hi Mike, I don't get over your way much but thanks for responding. Ken

-

Hi TwoMikes, I get to Atlanta often, I have grandchildren in Powder Springs. Thanks for chiming in. Morgans Leather, Thanks, yeah it's a little hike. I didn't see the picture of your holster, I don't think you got it attached. I get to Macon/Warner Robbins pretty often as well, either to go to Bass Pro Shop or for a Bluegrass Association Meeting. Thanks for responding. Ken

-

Lowes carries these as well in all sorts of sizes. Ken

-

I've included a picture of the Tandy groover I use, it is the Pro Stitching Groover perviously mentioned. I have no problem with it and use it quite often. Ken

-

I thought about the tubing but not heat shrink, I'm going to look into it, however, the masking tape lasts for months and months and comes off easy if there is a need to do so. I thought about surgical rubber tubes in just the right diameter. Ken