-

Posts

101 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DR80

-

-

I found this site. French: http://www.mando.fr Translated to english: https://translate.googleusercontent.com/translate_c?depth=1&hl=sv&ie=UTF8&prev=_t&rurl=translate.google.com&sl=fr&tl=en&u=http://www.mando.fr/27-consommables&usg=ALkJrhg0Lz8QFtw-fegGgLc9lLoCG_dURQ Can anyone tell my how these works, i guess it's in combination with a Fileteuse. If you use either of the products i would appreciate some pictures on finished edges..

-

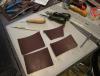

Here are the pictures on my finished prototype. Not an easy task to take edge pictures I wish my burnished edges was as smooth as this.

-

When i'm using Fenice i don't burnish the edge before the first layer. The reason is because it impairs the adhesion.

-

I don't know really, but i like it. The adhesion seems really good. But like i said earlier, och don't like it on all projects. I'm going to use it later on Chrome tanned goat. Here you have it in english: https://translate.google.com/translate?sl=de&tl=en&js=y&prev=_t&hl=sv&ie=UTF-8&u=http%3A%2F%2Fwww.ds-leder.de%2Fink-edge.html&edit-text=

-

This one: http://www.ds-leder.de/ink-edge.html It depends on if the edge is trimmed after glue or not. But a trimmed edge is 2-3 layers. Not trimmed 3-5 like you. I bevel the edge with the smallest beveler (size:0) One thing i think is important is to "burn" the first layer of paint (with a wood burnisher/canvas or fileteuse) How are you doing? I can show the result of my prototype's edge when i'm done.

-

Yes it's true. It looks good, but for every piece i make i want do to things better. "with all their expensive equipment and so on" The interesting part here is what equipment do they have that makes those edges better. I need that equipment or a "working substitute" to that equipment. Just now i'm working on a watch strap prototype with padding, i can't explain why, but on those edges i find it nice with Fenice on the edges, on the finished piece i will probably use a gloss agent too.

-

Watch Strap With White Thread.

DR80 replied to DR80's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

9 SPI, thank you -

I like to make the stitching line before i bevel my edges. And i have to sand before i make my stitching line The quality of the leather is good.

-

I'm not satisfied with my edges, or rather the life of the burnished edges. I get a really good result with Fenice edge ink (Not Tandy's but probably the same.) but it gives a little "rubber feeling" which works on some projects. The way i burnish. 1. Sand. 2. Bevel edges. 3. Burnish with saddle soap (burnish, sand, burnish..) until i'm satisfied. 4. Dye (Regular oil dye) 5. Final polish with Beeswax. The initial result is good enough for me. On things like a credit card wallet the durability is good, on a watch strap the edges soon looks worn. And if i fold it (a wallet, notebook-cover or something like that, it becomes small "cracks" in the finish where it folds)) Is there anything i should do different? or is there something better to use? Beraud? Attached an example. I hope everyone understand me despite of my bad grammatics. Thanks in advance.

-

A Slim Card Case.

DR80 replied to DR80's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Cowhide from Japan. -

Another Watch Strap

DR80 replied to edd's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Really nice. How thick leather are you using? -

-

Lc tooling from Leathercrafttools.com The leather is nice, but a little expensive with shipping costs for larger projects. Thank you.

-

Thank you. First, they are glued. And i burnish them before i stitch. But the most important is too take it a little easy with the tension of the thread.

-

-

I'm looking for some leather for wallet making. I have seen a lot of nice handmade wallets in chrome tanned leather. When i look here http://www.tanneries-roux.com/english/products-english.html How do i see which leather suits my requirements?

-

Belt For My Grandpa

DR80 replied to mpluc1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice -

Green And Taupe Bifold Wallet

DR80 replied to Petewon's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Do you mind sharing what books you bought? -

Thank you Im planning a bi-fold wallet. (http://leatherworker.net/forum/index.php?showtopic=65688&hl=) But i have changed it a little. Backside 4oz, front and credit card pocked 2oz.

-

Then i need to make perfectly aligned stitching holes on both pieces, and align them perfect when i glue them together.

-

How do i punch straight holes in skived leathers. (see my attached sketch) If i punch one part and then glue them together i can open the hole with an awl, but i'm not satisfied with the result when making the holes with my awl. (Nothing wrong with the awl, a new sharpened diamond awl from Craft Sha.) I want to use a stitching chisel, but wonder how, or if it's possible in this situation?

-

Made som strap-ends. 10-33mm, 34-45mm. 10-33.pdf 34-45.pdf