Gymnast

Members-

Posts

294 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Denmark

-

Interests

Applications for gymnastics. Repair of tarpaulin covers and with webbing. Rubber rope and terminations.

LW Info

-

Interested in learning about

Sewing machines and ways to use them

-

How did you find leatherworker.net?

Google

Gymnast's Achievements

Member (2/4)

-

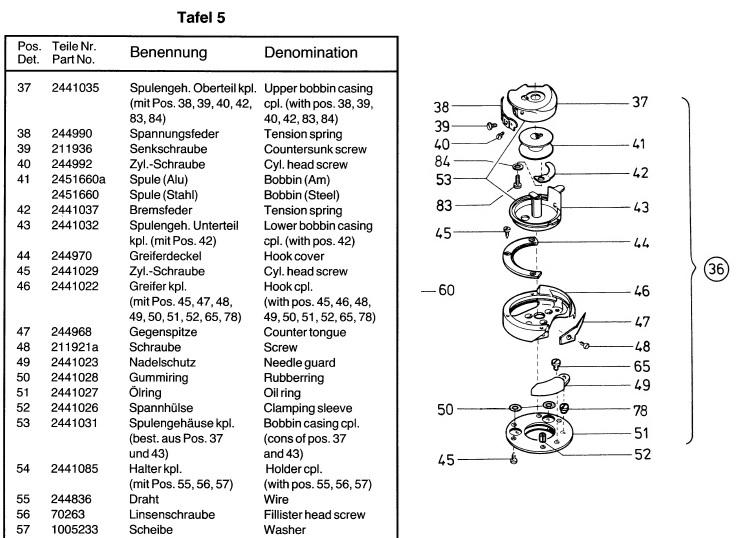

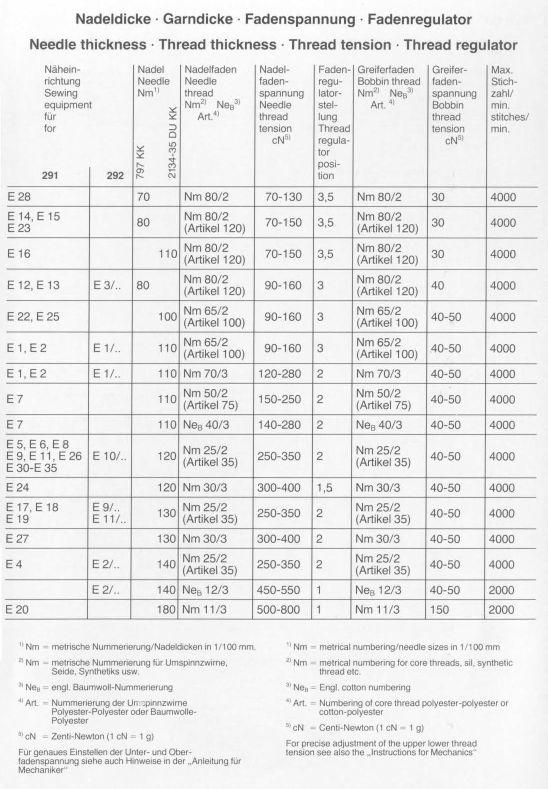

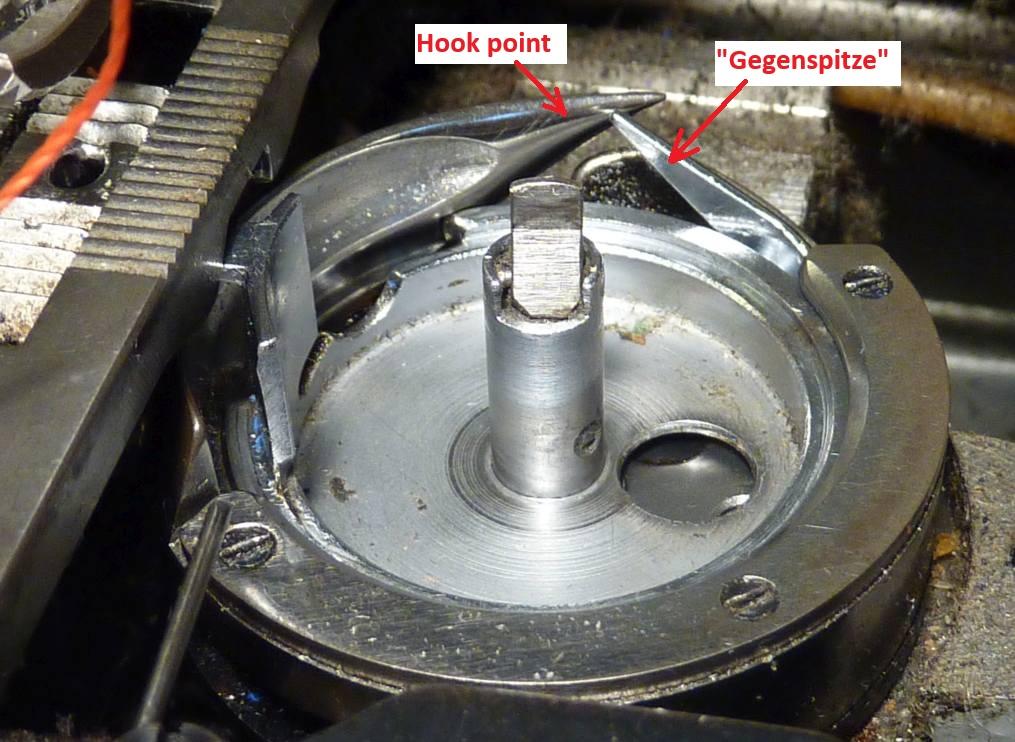

Many thanks for your good and helpful answers. I will try to comment and answer questions. This machine is owned by a Fablab (community workshop) in Copenhagen, and it was donated from a previous leather shop. It got the subclass E1 designation, and according to specifications, it is for max thread size of Tex 70 (V69) and 110/18 needle size. The machine is a tripple feed machine, and it was made to sew very fast (4000 stitches/min) within some limits of stitch length and materials. It came with a clutch motor and it was geared for fast sewing. According to specifications and from my look on them, it is not the best machine for a leather shop, but perhaps they got it from somewhere else. The Fablab intent is to use the machine for light and medium heavy fabrics and up to Tex 135 thread and likely not below Tex 70. So I have given the machine another motor drive, and the speed is now limited to 1100 stich/min. For normal use, the electronics limit the torque on the sewing machine shaft to 3 Nm, but it can be increased to 8 Nm. The Fablab got many users, so the machine will be used for various jobs and settings. The users will need to attend a course before they use it. I should like to know about experience on such kind of sewing machines on this kind of community driven workshops. This is a table of the subclasses: This is the drawing and part list of the hook for the Dürkopp 291. It seems like alle the subclasses got this "Gegenspitze": A German author, Wilhelm Renters wrote a (to me) very well written 3-volume book on sewing machines in German language. The last edition is from 1957. I think it have been used for education of sewing machine mechanics in German language countries. He named this tip "Gegenspitze", and this term can be found used more places. As you see above, the previous Dürkopp translation is "counter tongue". But I have not found this name elsewhere. I guess "counter hook tip" would be a good name. Thank you very much for this information. I was not aware of this change in the length of the counter hook tip dependent of thread thickness. Yes, I made this video with my attempt on German language comments But I hope you get the Idea. A Serafil Tex 135 thread and 140/22 needle is used in video. https://www.youtube.com/watch?v=5fmdezeTUKk The sewing machine with this counter hook tip do work OK with the Tex 135 thread at various test materials, but I don't like the click sound, and sometimes the needle is moved about 1.5 mm to the side due to the high tensions pulled in this tip. I like to educate users to be aware of the sewing machine sound and don't accept something like this for the safety of the machine. I have tried to advance the timing of the hook, so the thread glides off the tip earlier. The nominal timing position is, that the needle have raised 2.0 mm (5/64 inch) from dead bottom position. The problem disappear when this figure is changed to only 1.4 mm (7/128 inch) from dead bottom position. I tried a timing with 1.7 mm raise, but with this timing I occasionally get skipped stitches. Just now I have removed the counter hook tip, and delayed the hook timing (as you have proposed) so the needle have raised 2.1 mm, and it seems to work with some tests of thread sizes and fabric. Of cause I did also alter the height of the needle bar with these changes. Thank your for the link to an alternative method for timing of a sewing machine. I shall try it on a few machines and make a comment in this other thread. Do you mean the throw of the check spring? Yes, I did try various positions here, and it did not change anything. You are also able to change the thread throw of the take-up lever a bit on this machine, and it did not change this either. I have looked the parts list and drawings I got, and they don't specify drawings of other kinds. But I now looked on the subclasses as you suggest, and for the heavy subclass E20 you got this comment: "With short hook counter-point for very resistant seams (Mit kurzer Greifergegenspitze f.extrem feste Nahtverbant)". The E4 version for not that heavy use, you don't have this comment. So it seems that some shorter Gegenspitze do exist, and I shall try to ask for it. I have measured the clearance between the lower bobbin case and the hook body, and it is 0.93 mm on the hook I got. This will of cause set some limit to the thread size, because some slack in this clearance is needed as well.

-

I know the German term, "Gegenspitze" for a point part of the hook, where the upper thread leaves the area, when pulled the last part up by the take-up lever. It is the point you see here: For some machines like the Singer 211W this "Gegenspitze" is part of the hook gib. My problem is, that the thread is pulled hard by the take-up lever on this Gegenspitze before the thread finally is pulled off the end of the tip. I have read, that the reason for this tip is to avoid, that the hook may catch or damage the remaining thread when it comes around the second time. I know that only a few rotary hooks got this tip. I have of cause checked timing and some other matters in order to fix this problem. One matter was to grind and polish this tip. It do get worse with thicker thread (I have tried Tex 70 and Tex 135 Amann Serafil). I know another user with another Dürkopp 291, that have used the machine without this tip and with no problems. And I have tried the same with some threads and fabrics, and I have not seen problems either. But I also have got some warnings about that from a sewing machine repair professional. I have also been told, that this hook have been made with specific differences, that may relate to subclasses. The original subclass of this machine is E1 and it is one of the early versions of the machine. I have tried to measure the length of this tip when taken off in order to possibly compare the length with other users: Do you know about the issue with this "Gegenspitze" and possible ways to fix it?

-

Well, already my post from above is 4 years old. At the moment I do some test on a Dürkopp 291 industrial combined feet sewing machine. I have tried to measure the presser foot pressure and on its minimum setting, it provides a pressure of 87 N (8,9 kg or 20 lb). Maximum is 220 N. To me this pressure seems very (and too) high. But the machine works fine on tarpauline. The picture below show how it is measured. I have tried to look up in specifications and service manuals regarding this and other similar sewing machines and have not been able to find data. So I hope, that you perhaps have seen that. AI answer that this pressure is 5 to 30+ Newton on industrial sewing machines. I found one newer Janome HD9 household sewing machine, with a specification up to 11 lb (5 kg or 50 N): https://www.janome.com/product/hd9-professional/#machinespecifications I hope that someone else might have seen this pressure specified on another sewing machine or perhaps have measured it.

-

Is backstitching with a leather point needle a problem?

Gymnast replied to Gymnast's topic in Leather Sewing Machines

Thanks for the answer. I think it is not entirely trivial to find out the problem, if the thread is only partially cut. One possibility is to make tests with many stitches, and then pull the thread out and see if it has been damaged. The type of leather tip on the needle can probably also be important. -

An experienced sewing machine guy in another forum have warned me, that there is a high probability, that you severely damage the thread in the leather hole, when you make the cutting needle point enter into the previous stitched hole. I have never heard of such a problem before, and I have not got that much experience sewing leather. Have you ever experienced a problem of this kind?

-

My answer is, that it is a bit more expensive, to make a motor drive with good low speed control, and there is not sufficient demand in the market for that. EFKA do make expensive motor drives for sewing machines with a wider speed range. In more technical terms, you got an issue with measuring the speed of the motor. For my drive I use another DC motor to measure speed, at it provide a very fast response. But it got brushes that will wear out in time. The normal way is to use digital encoders of some kind. For good low speed control, you need a speed loop response of within about 1 ms. If you have got an optical encoder of 100 lines (as I have seen on some the servo motors), the minimum speed will be 10 rounds/sec or 600 rpm. You can get more expensive encoders with 1000 lines - and then you get minimum speed of 60 rpm. But some of these encoders can then get problems at high speed due to a high optical frequency. There is more ways to measure speed, but in general it is not that easy, and it can become more expensive to do it. Another issue is how you control the winding current. The cheep way is to use three digital hall sensors in the motor, and it becomes a somewhat raw way of control the winding currents at low speeds. It is the old way of doing it for BLDC motors. More modern principles use the term Field Oriented Control, FOC, and they use other more expensive ways to measure the position of the rotor of the motor, and they use current waveforms near sine waves. But I think the pedal could be improved without extra costs, and it puzzles me why no manufacturer have made a change here. You need to focus on the force, that your foot provides on the pedal, because with your muscles you can control force much better than a position. For me the lowest speed is with a force of 4 Newton (0.9 lbF) on the pedal and 40 N (9 lbF) on pedal at full speed. For some pedals it is like 20 N for lowest speed and 25 N for highest speed, and to me it makes the machine much harder to control.

-

Needles breaking on Singer 15-91

Gymnast replied to lukeoliver1776's topic in Leather Sewing Machines

The sudden change could be, that the needle changed height by the needle is not sufficiently fastened or the fixing of the needle bar to the crank shaft is loose. So I recommend that you check the height of the needle bar. Have you got the service manual? The other thing to do is to remove the shuttle hook and clean this area for possible remains of thread. The shuttle hook always need good lubrication at its race. You need to use leather point needles as Wiz already wrote. -

Thank you for the moved post and answer

-

Thanks. I did not know about this trick. But then Google helped me to look it up, and it did not show up that many places. I found it here by Bernina: https://blog.bernina.com/en/2023/02/sewing-needle-and-thread/ I tried it on some known threads, and I think it will work to discard too small needles. My 207 thread and 140 needle was on the edge. But Google directed me to this other similar method as well proposed by Groz-Beckert: https://youtu.be/4fsQGtMSFEQ?si=2CGPJffRur3sgU8x&t=121 I think this method will accept too small needles.

-

I am just confirming the remarks by others. Something is wrong, when the hook hits the needle like that. Make sure, that you do not use a bended needle. It could also be the presser foot or feed dog that push the needle towards the hook. You should also make sure, that the hole in the presser foot and feed dog got sufficient size to the needle size you use. I think the machine manual should inform you about that. For my machines I got almost all sizes of needles, so I am able to alter them for different threads and fabrics I sew. The right needle size for V207 thread is above 140, but I have sewn some vinyl with a V207 polyester thread and 140 needle, so it is not like it should be impossible. It do also help to use leather needles for leather. The thread manufacturer will normally provide you with information about the right needle size. This is an example of that: https://www.amann.com/products/product/serafil/

-

In connection with my experiments with making a DC motor drive, I had the opportunity to measure the motor current consumption for a sewing situation. For DC motors, the current is close to proportional to the delivered shaft torque. I'm fine with getting some measurement results with numbers on some situations to get a better understanding. But for normal users I don't think it has any relevance. Maybe the knowledge can be useful if you want to experiment a bit with which motor you want on a sewing machine. The curve below shows the DC motor current over time for just above one stitch. The driver electronics ensures a very constant motor speed. This video shows the current situation used when the power consumption was recorded: https://youtu.be/N-FB2jHYyuw The measured mean torque here is approximately 0.5 Nm, while the maximum torque is approximately 2.3 Nm. This corresponds to a peak pressure on the sewing needle equivalent to 145 N (15 kgF or 33 lb). For these slightly more powerful household sewing machines, I use as a general rule to limit the torque to 3.5 Nm. My guess is that industrial sewing machines for leather can generally withstand a significantly higher torque. At higher speeds of the sewing machine, you will be able to get help to penetrate the material by taking the energy from the inertia of the motor and flywheel, which then briefly reduces speed. At low speeds of the sewing machine, there will typically not be enough rotational energy for it. I guess that for larger leather sewing machines you will also see a correspondingly large variation in the torque that the motor must supply to the sewing machine at low speeds. If you want to know more about the specific setup with this Pfaff 230, there is more information here:

-

vintage Singer 201k for edge binding

Gymnast replied to TonyGreen3455's topic in Leather Sewing Machines

Thanks. Yes, I guess the CB-bobbin allows for thicker thread, but the 201 actually was able to handle this thread as well. I guess, that when you compare a Singer 15-91 and a 201-2 in the US, that have got the same potted motors, then you will find the 15-91 to be better, because the 201-2 require more torque from the motor to operate thicker threads. TonyGreen is from UK, and these machines are belt driven machines in Europe (with few exceptions). Belt driven machines got more possibilities for changing the motor power or using speed reducers. I agree with the Northmount and Wiz, that a walking foot machine is better for leather and jobs like this. But TonyGreen asked for advise on smaller household machines, and some of them can do some jobs too, if you modify them. -

Hello kgg My YouTube channel got some more videos with this sewing machine. This is a speed test with some remarks using the original motor: https://youtu.be/VLU_s1RGasA This is more about the mechanics regarding the new DIY motor drive: https://youtu.be/Ig69cM_0w7Q The pedal is like you see and attached to an air pressure sensor. Some electronics and an Arduino microcontroller is involved as well, but I have not yet made any "nice" documentation of that yet. To my knowledge, the important thing about the pedal is, that you need to have a large range of pressure applied from minimum speed to maximum speed of the machine. I use a pressure of 4 Newton (0.9 pounds) for minimum speed and 40 Newton (9 pounds) for max speed. So you got a factor 10 in pressure needed that allows for precise and fast control by the foot. The possible length of compression of the pedal have much less importance. When you using air as I do, you will have have a pressure change due to temperature changes (ideal gas law). Therefore a zero point adjustment are needed by some manual setting or by some software (I use software here). Furthermore the software implement some unilinear function, so you can get more accurate low speed control. I use parts of a parabola function. You are welcome to ask for more specific details, and I shall try to provide them.