rac1812

Contributing Member-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by rac1812

-

Update.....good news...... persistence paid off. First off I was given a link to a clear, hi-res copy of the operators manual to circumvent the photo copy of a copy of a copy and can nopw see the arrows and bolt numbers,........and was reminded to RTFM.....so I read the operators manual and all my answers were there....... Found it difficult to go with accurate mm measurments when it says to tap gently so fell back on my mechanic feeler gauges so a close fit is wehn I can slide easily a 1.5 mm between the needle and the needle deflector...etc. after moving the complete bobbin assembly back and forth and moving the gear drive back and forth with the help of a second head and a third hand...... we went back to square one as per the singer assembly plant and removed the bobbing holder..... recentered the drive gear and were able, using the cut groove in the various shafts get a close line up of the hook....... than fiddled for fine adjustments. If you take the time to find the one set screw that actually locks on the grooved shaft, using a flash light in the set screw hole, you can do wonders. By the end, about 5 hours later, we manually rotated the machine to stitch us a nice even stitch at 5 to the inch.....tension just about OK on heavy canvass...... tomorrow we power up so I can finish my side curtain.......also trashed the existing needle as we discovered a "burr" on the tip,,,,,,, had more in stock.....so set up for #92 thread, top and bottom, with a # 20 needle. Bought a replacement needle plate that will not fit as the Vee groove for the machine screws was not done deep enough...... will adjust with a stone on the drill press at a later time. The new made in China bobbin holder was checked with a micrometer and was very accurate....... Thanks for the help, moral support and all the positive vibes sent my way!!!!!!

-

Duh ....yes..... never looked at it....... so off to the workshop to test it out. Thanks

-

Help I am over my head...... My 211G156 is malade........ I replaced the whole bobbin holder assembly with a new one and got the new sharp hook line up with the needle..... played with the gears....... Now it jammed with a bird nest and I forced it forward........ something went cluck........ could the rubber drive belt have skipped a tooth????? So my main question is....... how do you time the belt gear which has a nice arrow slot.... against what....... there must be a second mark somewhere that need s to be synchronized with the main drive gear....AND WHERE IS THE ADJUSTMENT???? I believe there was a video of the process but can't find it...... I have the needle bar height and the bobbin/hook adjustment down pat..... but something else is off as the material does not feed properly........ working on the sewing machine is good practice to develop "patience ..... as bigger hammers do not work!! Now for a beer!!!!

-

......Wiz...... just to let you know that I have been following these posting for possible application to my 211g....every bit helps.....

-

Meanwhile, in the cooler air of the barn, I removed my hook and bobbin assembly. Had to make some screwdrivers with 90 degree bent shaft and wise grip to loosen the screws. Cleaned all I could....removed the gear and now satisfied that there is NO way to shorten the kwill shaft a few millimeter as the length is set by the machined bottom of the bobbin holder. So back in it went...lost my hook setting but easily adjusted with slight movement of the carriage...... I was able to preserve the timing by looking in the set screw hole and see the mark on the shaft and set my screw right on it. If nothing else I am learning the mechanics of the machine..... it is intimidating but not impossible. Tomorrow will pick up my new thread, needles from the UPS across the border..... my chinese parts I get mailed direclty to the house....cheaper and faster. Thanks for the help Cowboy Bob........... once I get my spare hook/bobbin assembly I may dare filing down the tang/tab to see if I can eventually do #138 or remove still more steel from the needle plate

-

To Mule Saw in Denmark......... his machine is a British United Shoe machinery NO 6.......has the name Pearson and Bennion cast on the arm...... was featured on this forum some years back. Working on a trial run later this week when the tail end of Hurricane Beryl reaches us with torrential rain....... hoping his basement is high and dry..... Stay tuned.

-

I have written him asking for a photo...... I know he fabricated his own base on casters and he did separate it for bringing it in his house.... he is a fixer jack of all trade and knowledgeable .... he was fixing all kind of machines free for home sewers making face mask during the Covid 19 crisis....... BUT also a collector, machinist, unofficial gunsmith, etc..... also 35 miles from my place!!!! I agree that borrowing it might be a good investment of my time. Stay tuned.

-

Update........ no luck lowering the Hook/bobbin assembly.....but moved the carriage to the right too much and it no longer hooked the thread.... readjusted and broke my first needle....readjusted better now it works again.........finally went at it with a diamond jeweller's file on the groove of the needle plate...... took a few tries but NOW it works #90 size thread....... should I get bold and try for #105 and eventually 138 size beige thread.... I do have a spare original needle plate to fall back on now..... it is tempting......BUT does anyone know whether if it will work on the smaller thread again...... Found a Singer 144WSV37......20 inch bed fully cleaned and set up....was used to do cardboard door panels for cars......Needles seem to be rare to find but nice large bobbins....... but can't justify the cost nor the pick up distance......... meanwhile I may have found some one who will let me use his HD patcher machine....huge thing to big to move out of his basement....... since it has not been used your years ..... I suspect that I would need a few hours to clean it and properly set it up and then do 15 minutes of my sowing..... but it is feasible.....owner claims it handles #346 for harnesses and saddles....... it is not a singer possibly a Pease???? massive hand pulleys works with two pedals..... Still experimenting and learning.....

-

One more question......... some one else is using a bigger thread on a 211G ............ is there a big difference in using 135 "poly" as opposed to 138 bonded nylon?????? Advantages VS short comings...... Found my answers....did a search on Google and it referred me to previous Forum posting......ain't technology wonderful.....

-

Will try to answer al of the above........ Yes I may need a new machine that can handle at least 138 or better still up to 207........ have to rationalize the expense since I am doing linited number of parts for my truck restoration.... a hobby not a bread earning proposition..... The idea of borrowing the use of a machine may be more practical ..... there are a few shops left that caters to truckers and for boat covers and will look them up.... they may be a good source for buying used machines or even paying to have the limited sewing I need done........ it just that I enjoy the satisfaction of doing it myself.......approaching the Canadian military is like..... the poor sods might want to use my machine !!! To Bob Kovar..... yes I have learned the hard way that if you do not hold on to the threads you usually pull out of the needle and have to rethread the needle....which means removing my eye glasses, squinting and using a metal wisker device to rethread the needle..... Now to get technical......... for both Wizcraft and Bob....... as I can easily slow down my machine to single stitches ......I have observed.... with the steel sliding cover removed.... that the hook turns clock wise and picks up the thread from the needle....and said captured thread slides over the bobbin completely to do the stitching knot........ and repeats for the next stitch....... as it passes over the hook/bobbin holder it eventually slides over the "tang" that is held in place by the slot in the underside of the needle plate......... on my 211g it seems that the space/clearance for the thread to slide through is fine for #90 thread but does not allow the 138 to slide past the tang and a bird nest develops.......... the thread seems to slide on top and past the bobbin latch but gest hung up on the "tab or tang"....... Dikman and Keith...... as best as I can observe the thread loop over the bobbin and slips bet ween the tab/tang and the bottom slot of the needle plate..... but will look again.... Is there a way to increase the clearance on the tab/tang by honing the tab and or the needle base plate??? I have ordered a new needle base plate in case I f&&* up the the one I have....... I just want to much to use the beige 138 thread I have as it really resembles the old stitching of the original side curtains..... Wizcraft.... when you say moving the hook assembly slightly to give more clearance for the tang....... how did you do that???? when you remove/replace the total hook assembly is there and adjustment that allows movement.....I remember just dropping the newer one in as a single unit reassembled then fined tuned the hook itself by tapping the hook and looking at the process very slowly while hand turning.....making sure there was no burr on the hook...... I may have missed that fine adjustment when installing the whole hook unit..... and I do have a new one as spare..... Thanks for all you help guys.... not easy to solve this kind of issue by texting...... much appreciated. Bob C

-

UPdate...... after some fiddling I have the 211G set up for T70 bonded nylon.......... just needed to readjust the tension....... BUT....... my goal is to be able to use the#138 beige thread and possibly my 207 Beige to reproduce the old heavy cotton sewing of the 1940s......... Do I need to shop for a heavier machine???????

-

211G dead in the water,,,,, I tried the largest needle #21 with the 138 bonded nylon thread..... the machine does two stitches and the thread jams under the feed plate and is strong enough to stall the machine and cause the belt to slip. My detective work as shown the same issue I suspected yesterday....... the 138 is tooooo big.......let alone the 207 I have. Now Wizard who has a 211G will understand, I hope, what I will attempt to describe........ there is a plate held by two screws that fits over the dogs that move the material..... that plate has a small slot underneath that holds the 1/8 protruding tang from the hook bobbin holder and keeps it stationary. During the looping of the thread over the bobbin the 138 thread has to slide in the limited space/clearance of the tang and the slot in the top plate..... mine gets hung up and does fancy birdnest....... the stitching knot never gets completed.....and jams. I have tried raising the top plate by inserting a small strip of the canvass (at both ends) I am using as a shim thereby slightly raising the top plate to give clearance for the thread..... did not work....... The dog has been replaced with a new one with good teeth. All my test are done with two layers of heavy canvass....thick enough to hide the large thread. Is it feasible to carefully hone the clearance on the plate with the inset for the tang to allow larger thread or am I butchering the machine....... could buy a new top plate to try the honing approach Am I going to be limited to using thread size under 120??????? I have not tried any more adjustment on the tension as I can't sow.......... Fall back plan for now is to use T70 Olive drab thread bonded nylon and play with the tension to match the thread size....

-

Now that I have cleaned it, adjusted the timing and installed a reduction (home made) belt device and added a variable speed motor from Toledo I am actually using the beast. It is very slow unless I stomp it but that is what I wanted. All of the above was done with forum members advice so now I need "operating help" I am in the process of making curtains...... not for the kitchen... side curtains for a 1940 army Chev....... using very heavy Olive Drab Canvass. I made a pattern using flipchart paper with 1 inch squares and taking measurements from an original side curtain made in 1940...... can't use the original has it is now 2 inches too narrow and 1 inch too short..... well it shrank over the last 84 years. All the stitching is fairly simple straight line using a very coarse cotton thread........ my goal is to copy it as accurately as possible both for size and visual appearance..... so I have modern cotton canvass around 16 ounces, and various thread size in beige, to mimick cotton and transparent vinyl to replace the original totally degrade Monsanto early plastic. I have completed my first prototype with # 69 black nylon bonded thread using a Number 14 needle at 8 thread per inch....... did the needle thread trick until It moved freely in the fall test...... results is a fairtly good looking curtain that fits the side opening. My next step is to do another one using the heavier beige bonded nylon at the lowest setting of 5 stitches per inch....... Now I need help....... my largest needle currently in stock is number 21 and the 207 bonded nylon is too big for my needles..... and in fitting the newly wound bobbins I noticed that there seems to be a clearance issue around the bobbins many hooks and crevices........ have I exceeded the thread size limits of my machine??? thread is a very tight fit on the 21 weedle size I have and does not seem to loop over the bobbin when the hook turns over........ I intend to respect the limitations size if that is the issue...... or is there a way around this???? My next attempt was to use a 138s bonded nylon in Beige with a number 20 needle........ well I expected that the "tension" woold need to be adjusted....and was not disappointed..... first test was a typical bird nest under..... increases the tension until I could sow but the bobbin thread is lying flat on the underside and the top thread very visible sticking out of the canvass......... pretty well maxed the tension adjustment screw and now it is almost acceptable but the top thread is still being pulled to the bottom......... what do I do next??? technical question.... the tension mechanism is a two screw./ disc arrangement....... and I have been limiting my tension adjustment to the top most screw..... is there anything else that controls the tension that I am overlooking....... I have not touched the bobbin tension screw on the bobbin holder as the bobbin thread does not seem to be causing the issue....... or am I wrong and the tension needs to be balanced somehow??? Otherwise the machine works nice and handles up to 7 thickness of folded canvass when doing corners at a steady clunk-clunk-clunk with plenty of torque. Am I possibly using the wrong kind of thread??? I will be using my leather triangular needles when doing the vinyl. Any help and / or suggestions greatly appreciated. My next project will be attaching leather straps to the truck cargo box canvass....single layer of harness leather to canvass with a stress patch/ piece of 9 ounce leather on the back side for greater load bearing. For this I will be fabricating a temporary large "L" shaped table made of two 4x8 sheet of plywood with me sitting in the crease......... again tread and needle size will be an issue. Thanks for your help. Bob C.

-

How to choose the best servo motor for a Juki LU563

rac1812 replied to ValJ's topic in Leather Sewing Machines

Just to let everyone know....... I followed the advice from the forum.............. my 211G156 runs perfectly smooth with the home made reduction box and the Toledo 550 watts motor. Works nice on heavy duck canvass up to 7 layers and can do the curves at chunk-chunk-chunk speed no problems....... I wanted slow to match my skill level and it delivers......... have yet to tackle the leather straps but with the proper needles it should be a breeze. Biggest problem now is bobbin size....... and making a temporary larger table with sheet plywood. Thanks for all the advice. Bob C- 19 replies

-

- servo motor

- slow down machines

-

(and 2 more)

Tagged with:

-

How to choose the best servo motor for a Juki LU563

rac1812 replied to ValJ's topic in Leather Sewing Machines

Thanks for the all the advice...... which I followed ....... and encouraged our advertisers/supporters ......... and beautiful downtown Toledo, Ohio is sending me a ConSew 550. Now to sit patiently for it to arrive................ will be picking it up at a USA addy across the border and do my own brokerage...cheaper that way.. Good competitive price including shipping. Will post my progress in due course. Bob C- 19 replies

-

- servo motor

- slow down machines

-

(and 2 more)

Tagged with:

-

After all this time, the basic information is still captivating. It got me going back then and still going today. A ...BIG...thank you Eric. I did make my own reducing hook up with pulleys following advice and videos posted on the forum Now moving on to installing a servo motor, again following advice from this forum.......... will try it first without the reducing set up and may eventually use my reducing pulleys for even more control. You guys make this forum Priceless!!!! Bob C.

-

How to choose the best servo motor for a Juki LU563

rac1812 replied to ValJ's topic in Leather Sewing Machines

Good evening KGG ......nice to see a fellow Canadian. I am using a cleaned up SInger 211G156 Walking foot for canvass seat covers and now for fixing leather straps to canvass truck covers...... Not being very skilled at sewing....... the high speed clutch motor was the first problem......solved that by building a belt reduction device box that roughly reduces 10 to one....so max speed now is around 300 rpm. BUT...... I don't seem to have much torque on start up so nI punch the pedal and it "kindda" jump starts on me..... and I jump....quality suffers...... I need something like a patcher that goes chunk kachunk kachunk and can be guided easily by hand. Will installing a 1000 or 1500 watt servo....with or with out the reduction set up work?..... and I realize they all seem made in China but do we have reputable USA or Canadian retailers to recommend.... I do have a USA UPS box for direct mailing. will a servo work??? what kind??? what power? Thanks Bob C Living a slide East of Ottawa....and better at restoring old CDN military truck than sewing.- 19 replies

-

- servo motor

- slow down machines

-

(and 2 more)

Tagged with:

-

Anyone Tried this Speed Reducer?

rac1812 replied to KeithHideWorks's topic in Leather Sewing Machines

Thanks..... will be working on extending the control arm.... I found a high quality 8" industrial pulley with screwed sheave.........real heavy like a flywheel ....but I am at a lost for a larger pulley that will fit the head........ any suggestions short of machining on??? Bob C -

Anyone Tried this Speed Reducer?

rac1812 replied to KeithHideWorks's topic in Leather Sewing Machines

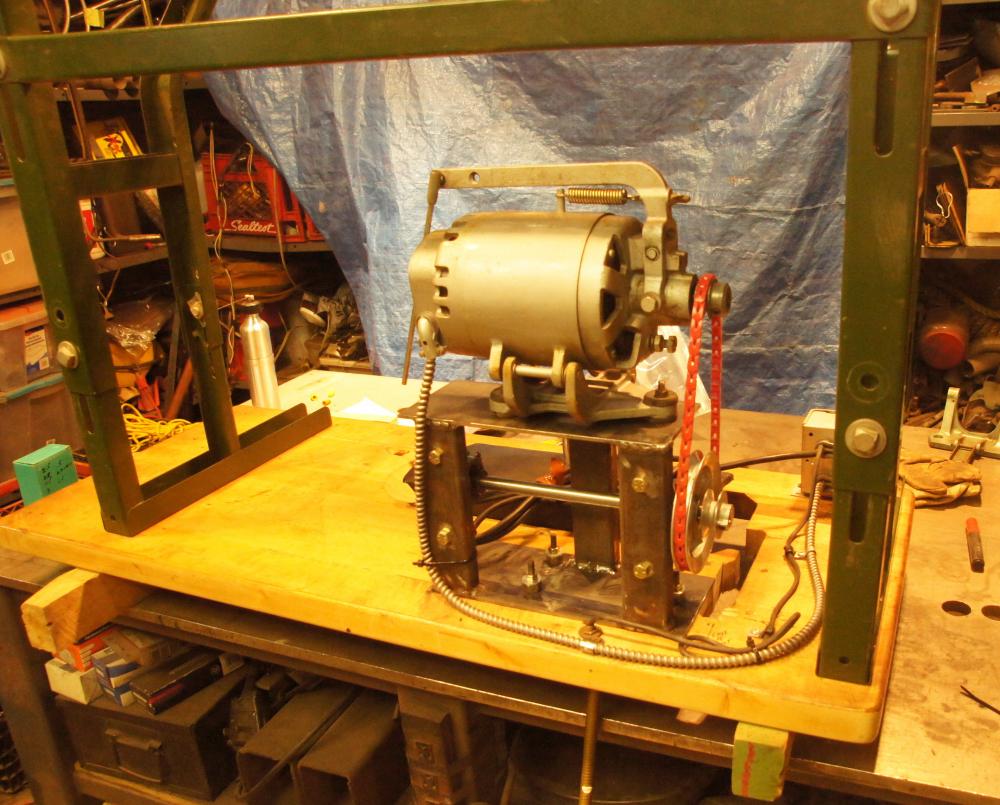

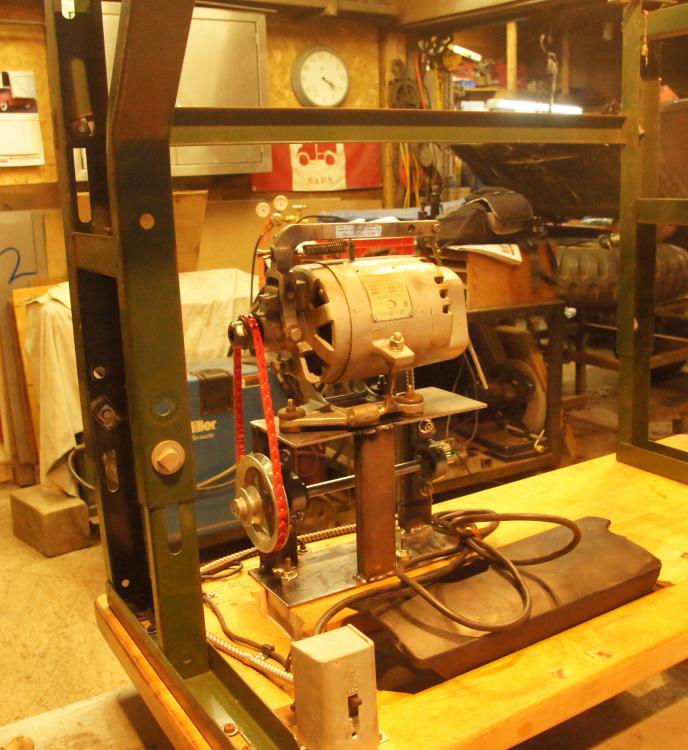

I have been vacillating between a servo or a reducer pulley. Finally decided to go with the pulley system has I could make my own. I am running a Singer 211G156. Already swapped the motor for a 1750 rpm and that helped but not enough. Based on the video from the forum and various system designed on EBay .... we built our own. Basically we dropped the motor to male room for a reduction pulley....motor went straight down so the final belt driving the "head" was in the same location and allowed to use the bobbin winder to remain in its usual place. If some one can be so nice as to inform me how to post pictures I will gladly share my design. I installed a 1.5 in. pulley on the 1750 rpm motor driving a 5 inch pulley on the jack shaft..... in turn the jackshaft has a 2 inch pulley driving the head 3 inch standard set up..... my overall reduction is 350 RPM flat out at the sewing head pulley. The first two pictures are not for readers from Australia...... we choose to work upside down for greater ease. Did a few test strips and it is much easier to maintain 100 or 200 rpm. I used two 3/16 thcikness..... 5 by 10 plates and three rectangular 1x2 tubing 9 inches long Two Taiwan 5/8 pillow block and a few bolts Needed to rewire the motor has the new positioning made the original cables too short to reach the switch. ,,,,have not given up on a servo..... but need to gain more practical experience with these mods first -

Hey it's been a long time........ sewing got put aside when the fair weather returned last Spring.....Winter is here and time for indoor sewing activities. This is more of a follow up and a BIG thank you for all the help you all have provided me..... the videos were worth a thousand words. My 211G156 is now sewing very well....... had to get a few parts BUT the information on the tuning/timing was priceless. I have installed a used 1750 RPM motor but it is still too fast for my skill level and for doing small stitching such as leather/canvas straps on truck cargo cover. Still cruising the forum for information .....silently as I have a steeeeep learning curve. I am a member on other forum sites and they have provision for donations to help with the admin/operation of the web site....... do we have such a process??? Next step is building/installing a jack shaft speed reducer and possibly a servo...... may seem like wearing suspenders and belt.....but I would rather be slow and high on the torque band and better quality. Cheers Bob C

-

Thanks Kris The last set of pictures, once blownup and rotated gives me a very good idea how the fabricated lever interacts with the small triangle part that pushes the rod to release the thread tension ...... should be able to make one and if that works make another one for Grant, a partner in crime who as the same machine also with missing knee lifter........ why are so many machine found with the knee lifter removed??? Bob C

-

Unravelling The Mysteries Of The 211G156.

rac1812 replied to rac1812's topic in Leather Sewing Machines

Thanks for all the advice guys. As they say information is priceless. Will focus on #92 thread size to start with..... have a variety of needles coming off Ebay from 18 to 22 in regular point and leather chisel point. I did not buy the round point needles as I was under the impression those were used with synthetic fabric and you would not want to pierce the woven threads. Was I wrong???? Now is the time to find out before I bugger up good Olive drab material. Following a suggestion for doing the set up using a 1/4 in drill depth guide I cornered a set of doeas at Lowe's.....now I can move on to the needle/hook/needle guide part of the process. My sewing machine work is done in a heated garage/barn right now and the night time temperature willbe around -25 Celsius which means at least 4 hours of blazing fire in Lucifer to bring the ambient temperature to about 45 Farenheit........ hard to work on those small screws with gloves and wearign a parka. So I am spending my time doing door skins on the 1940 Chev...... at least the heat from moving around and using the Oxy - Acetelyne torches helps a lot. I have on order a needle bar thread guide and was thinking of modifying another NOS thread guide to fit the existing screw hole where the oiler felt was installed. Looking forward to properly setting up the needle/hook/bobbin when the weather gets a little milder. Still playing with setting up a knee lifter bar at the back at least so the lifter will actually release the tension on the front thread tension set up. Will be down loading some of the videos and still pics that you have sent or found on ther web onto a laptop so I can have the information in the shop close at hand. Again thanks for all the help and will post my progress or frustrations as they occur. Bob C -

Unravelling The Mysteries Of The 211G156.

rac1812 replied to rac1812's topic in Leather Sewing Machines

Hi Eric Under what circumstances would lubrication (silicone soak or otherwise) be needed....? My heavy sewing needs will be to primarily deal with canvass tarp material referred to as 18oz. The tarp is made but will need some modification to repro a 1940 style tarp with roll up sides. That implies adding leather straps to allow the rolled up side to be held securely in the up position. Said leather straps will need some canvass reinforcements to be sewed in where the straps will attach. In lighter canvass, probably in the range of 12 to 14oz, we will need to make individual seat covers and back covers with a small piping around the edges. We have original canvass covers but do not wish to actually use them but prefer to make new covers for everyday use/wear. Those NOS dated 1940 covers will be the basis for making patterns. Our first run will be using plain white canvass of same thickness so we can learn and possibly have proof the paterns are accurate...... then will tackle the real ones. We also have numerous other canvass items to reproduce such as transmission shifter boots.... truck has 2 tranny towers, 2 emergency brakes and a starter lever that all need boots to control dirt/water from entereing the cab. Also need to reproduce bags to store the canvass side door windows and that includes reproduction the canvass side windows with new vinyl inserts. Will be wroking from some NOS and some tattered remains. Any suggestions regarding thread type....size... needle style and size would be appreciated. We have ordered some small quantity of 18 to 21 regular point needles and some similar size leather wedge point which we will use for our set up and testing of the machine. Trying to get it to work reliably before sinking more money for a servo........ which form what I have read should be brushless and at least 755 w to insure proper torque at the bottom speed range. I have already changed from a 3450 rpm motor to a almost new 1750 motor and it is still tooooo fast for good control. Bob C -

Thank for the very clear pictures. Did you get the origianl bar springs readily available or make your own.? Similarly did you start with an existing similar fit bar or make the bar from scratch? We have reproduced som amny truck parts we should be able to do like you and male one. I don't particularly like using the knee lift being more accustomed to reach bar to the hand lever.....but as it stands on my machine when Iift the foot lever by hand nothing is linked to apply any pressure onthe rod that release the thread tension in front..... the two little parts that activate the bar to the tension disc are all there. Knowing that the previous Owner used this machine as is for years repairing/recovering school bus vinyl seats and even did sewing for us to see it worked is frustrating...... but I am determine to make it better. MOst of the small parts ordered will be here by late next week. Bob C PS...... NOw I have to figure out if I am going to down load all this precious information and videos to an old lap top and take it to the shop in the barn,,,,or,,,, take apart the sewing machine and stand and move it to the computer room in the basement of the house.