Coeta

Members-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Coeta

-

Just adding some images, I was always wondering why the stitches are having a slight stance to the left and not perfectly vertical aligned as can be seen for the rows not marked with arrow. The row with the arrow was my last test run to have the bottom and top thread nicely interlocked took me a while to get it fixed.

-

Managed to get old fossil to work...needlebar height was not spoton ...adjusted the tension and the stitches locked nicely

-

-

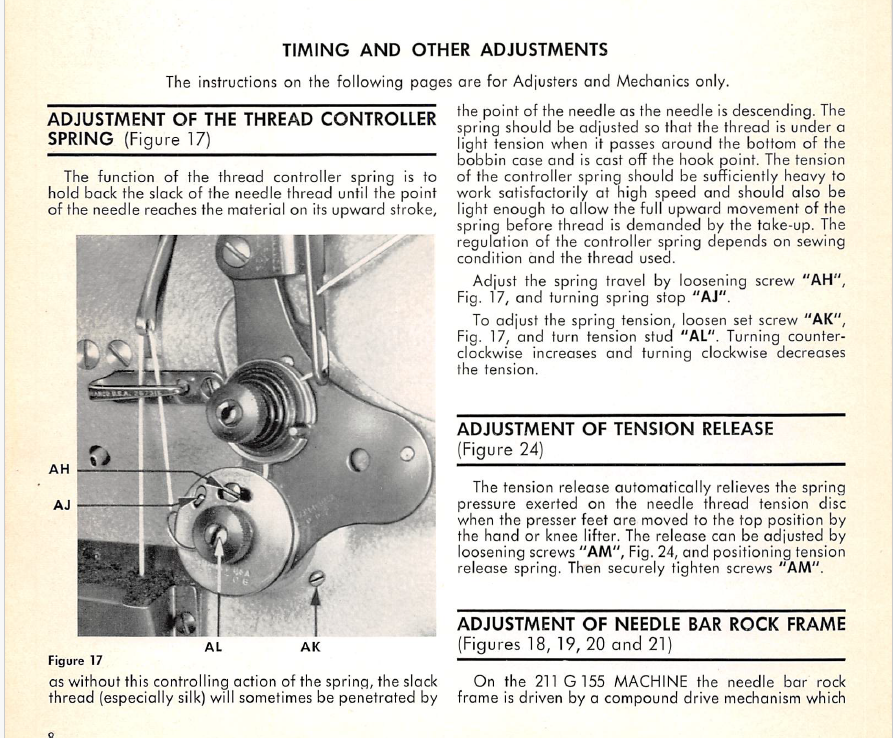

thanx for the detailed response I am absolutely sure I have thread it correctly, I think the issue is with the take up spring just after it goes through the tension discs , I dont know how stiff it must be, with it been very stiff it still is not enough to pull the thread back through the material to straighten out the loop on the bottom of throat . I have used the following link as a guide but as said the tension is much stiffer https://www.youtube.com/watch?v=uQ0i2f-q0i4&t=185s

-

Well it's time again to resurrect the old baby .......3 years down the line and it was never used, a new project is on hand, it looks like if i need to start from the beginning setting it up, what I found problematic is with the tension of the thread something is not correct as it brakes the thread Turning the handwheel to check the timing the hook is passing the needle and is picking up the loop when the needle goes up, turning the handwheel further so that that the hook comes around a second time the thread still has the loop formed at the bottom of the thread plate this the thread has not been tensioned by the tensioner while the needle goes up, I have adjusted the spring so that its very tight but still not working, I might have to struggle a while before I would get it to work again. Any tips as this was used 3 years ago....

-

Got it fixed but then I adjusted the pressure foot height as I was working with thick leather, then it did sticth anymore doesnot pick up the stitches, so I guess i did not tighten the gear screws enough..at least I know where to fiddle now

-

Also checking on the parts list for the hook pinion gear, I noticed that there is thrust washer present 224022, that is the part that is missing where I have lifted up the lower bush to take up the free play.

-

I will check out the case opener as that is the only thing I have not really checked, just eye balled it, I can also confirm that there is no up or down movement in the hook and this cannot be adjusted on the 166 As for the statement: Be Sure Hook Driving Gears are Correctly Set with relation to the face of the hook saddle. Use .008" Shim". I'm imagining we use a .008" shim between the gear and the saddle to set end-play? It's not clear from the manual. I am not understanding this .... Edit...got a more english version of the manual and it's more clear now, checking the distance I can confirm it's much more than 1mm I will need to fix this...

-

Some setting on my timing is not correct , I struggle a bit finding what might be wrong when turning the wheel by hand I got about 3 stitches then it is slicing/separating the thread when the hook passes the scarf of the needle, watching it from the bottom during the upward motion the thread is creating a little loop on the bottom of the material where the hook catches it again when turning past it thus creating tremendous strain and breaks the thread, As the needle bar does not have marks on it I have set it up as described in the manual, with the needle to hook timing, Might it be the tension mechanism that does not take up the slack of the thread, ,,,Oh well it's patience that keeps playing a big roll here to get what the problem might be I do have one question though regarding the upward free play of the little gear below the hook , the hook pushes through a gear (the small one) then it runs on a driving gear (the big one), Referring to the fitment of the small gear it pushes through a brass bush that gets hold with a little screw , how far must that brass bush be pressed in the housing as i have noticed that the small gear have some upward free play of 1mm if you turn the handwheel forwards or backwards, thus it's causing a delay in the point of the hook timing to the needle to be in the centre line of the needle. I have loosened up this lock screw and lifted that brass bush upwards until there is no upward or downward freeplay for the small gear _ did I do the correct thing here or are there supposed to be any shims inserted on the top or bottom of the small gear to take up the freeplay, or must that bush be fully pressed down with the free play applicable Referring to gear - point nr 5

-

Resurrecting an old thread, Yep this was the last time I have used the machine, and in the mean time we have moved to another house and so the machine was neglected and stowed in the garage on the floor deep under the dust and the metal parts got some surface rust again, and sadly the tension mechanism got damaged, cant remember if I left it still working or not, So I have to work through this thread again to get the old girl operational again, setting the timing checking everything...

-

post some images of tubular straps done

- 11 replies

-

- shoemaking

- leather

-

(and 1 more)

Tagged with:

-

I would also guess there is too much friction/stiffness on the thread at the needle hole as Constabulary suggested... I had similar experience when I used that sticky double sided tape when preparing to sew the material together.. when I sewed I had endless trouble with the thread not been pulled up back quick enough by the regulator spring no matter how I adjusted it...that double sided tape was just to sticky for the thread to be pulled back quick enough....after I removed that tape I had no issues... With your experience you should be able to figure it out....

-

Horween bifold

Coeta replied to thefanninator's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

F#$@n nice!! -

wow this is looking very nice...keep it up very nice to some fellow's got skills

-

Uwe...what motor is set up with this Juki? This looks like a very nice compact portable system.

-

Examine the attached pic f=forward r= reverse stitches,,,the holes are not uniformly round they are longish,,this indicates to me that the feed are not correctly set as the needle is cutting the paper. will use your advise on lowering the feeddogs. on the reverse SPI - this is not close what supposed to be still struggle with the settings The front and rear gap at the feeddog in the throatplate on max SPI must the feeddog have the same size gap for forward and rear stitch or do they differ?

-

Lol.good luck with the young one...the material is called cordura 500g/cm we use it here to make schoolbags..very durable and weatherproof the 300g/cm is just to thin then a schoolbag only last 6 months..keen to see your note's

-

Well I stuff it up again..need to start from scratch settings...as I wanted to fix the reverse stitching length to be exact as forward. I realised after a week of oiling that does not sweat next to shaft entry points where they rotate on the super oilite bearings .....the oil channels were clogged up...I had to remove the shaft where the feeddog are attached thus lessons learned....if you stripp do it propperly...:-) See stitch lengths...I cant seem to figure out to correct it for revers

-

well finally I got the 211 to sew though I am no mechanic, had to learn how to use the thread tension system finally got it correct and I had a few threads onto the material...some minor settings might need to be tweaked as it will only do max 5 STI when adjusting the stitch length only one notch back the stitch is very small...so I suspect it must be the bottom cam that is not 100 % lined up also when reversing the needle hits the feeddog, when tested with paper it did not hit it tough maybe some screw is not fastened enough and got out of its position but I am getting there..then after about 20 stitches the thread breaks..... the thread is close to the hook point when it is under the throatplate,,cant see properly what is going on down there but I will get it fixed

-

The red circle in previous post...that shaft.....when the machine marks are lined up in the sync position what is the zero position that shaft must be on as there is pinned block for the reverse feeding.... With that red incircled screw loose so that the shaft can rotate I loosend the lock nut and bearing nut and set it so that there is no forward or rearward movement from the needlebar rocking frame

-

The pressure foot is makeing a deep pressure on the paper as if it is pulling it in the groove plate...what do i need to set to keep it from pressing it to far down

-

I really need some advice/assistance now...I have worked on this machine non stop for 12 hours for 2 days now,,reading paragraph for paragraph and apply it step for step as I read it but stil I did not succeed.I also got the clip from Uwe Grosse on how to setup the Consew hook timing. So thats why I put in another request for some help..maybe maybe I will get it correct: I have set the belt for propper sync. Stitch lenght to zero and corrected the needle bar hight for 2.4mm on the upwards movement,,got the hook as close as possible to the needle, in the centre line/thread and 1.5mm above the eye , set the needle guard as per the book So the timing is perfect. I set the machine up for synchronous feed so I kept it at 0 SPI , loosened up the reverse feeding mechanism and moved the crank to the centre. Needlebar rock frame - Adjusted the needlbar distance from the vibrating pressure bar to be 7.5mm. Then I set the stitches to max: Set the feeddog so that the valley are pointing out as much as possible and let the needle enter a little bit in the front of the middle of the needlehole. Then I loosend up the bottom set screw to adjust the forward stitch lenght to be 5 stitches per inch.then the reverse feeding mechanism for it to be the same length as for forward sticth and this is where my problems start I dont get the reverse sticth length to be the same as the forward length forward is 5 stitches per inch and reversed it stays at about 11 or 12 even after I have locked the screw on the bottom crank. When I turn the bearing pin to rest against the bearing block the stitch length does not change. Then I realised when i turn the handwheel the reverse feeding lever drops about 5mm and stops every time the needlebar reaches a downward stroke. So then from me been tired I mistakenly loosend the wrong screw instead of the blue I loosend the red one there was one cluck sound from something that was under tension and now its nomore... I dont get any further, cant get the machine to feed, although it is on the max stitch length it only stitch about 2mm,,,when I use the reverse feed the needle point get stuck on the feeddog....so basically the whole thing is no screwed after I loosend up the wrong screw on that top shaft.

-

Can you line up the B mark on the pulley with the cut out line on the casing Take then a pic of the shaft where you can see at least two of the cut out grooves in order so that I can confirm if the feed driving eccentric is correctly timed (in order to rule out if the shaft grooves is in the incorrect position) ...Eric I have checked the screws and some of them were in the incorrect position (flat headed ones on the groove and they did not lock the part on the shaft).. I changed them and are all correct now...thanx

-

Eric thank you very much for your input and the honesty from your side as mechanical expert and your inputs already given, much appreciated. One more and maybe or definitely not the last question .... The only shaft that were in fact removed was the hook driving shaft and I did take pictures during the removal of the parts but during the cleaning there were supposed to be a line/mark on the shaft to indicate the timing mark so as it is now there is no line visible .... in order to line it up again with the B letter on the belt pulley from the pic before disassembly it appears that the groove in the shaft for the screw's were at the bottom side. pic 25 I have used the groove on the inside edge of the shaft where the pulley slide over as the timing line(pic 22).......would this be correct before I continue with the rest of the timing... found the link to the rebirth of a singer ...currently reading and will reply again...thanx to all

-

Ok I got that correct the upper timing and lower timing,,,, mark B on the belt pully is in line with the cut out line on the casting and the the take up lever is in the upper most position the I slipped the fan belt over gave it a few turns checked it again and they are still lined up... ok the next step?

.jpeg.fd913572d771d994d73675ce698bcbd3.jpeg)