Chayse

Members-

Posts

127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chayse

-

Contents of the drawer...I was mistaken..most of the needles are 29x3...sizes ranging from 120 to 180. Couple bobbins and odds and ends. I will identify the other needles...there are probably 25-30 that are loose. I have no idea if the little oil can is original...nothing that says Singer on it...only a patent date of 1885. Couple screwdrivers and an extra handle for the hand wheel....

-

Here is a thought...if you are unable to find a replacement, you mentioned machining a new one. Curious if you machined the same diameter hole in a piece of stock to a depth of let's say 2"...overall shaft diameter, heated the end that is bent and slowly placed/pressed the bent end into the machined hole. I think it would straighten it and re-align everything. That would be kind of a last ditch effort if a suitable replacement cannot be found. I think machining an overall replacement would be challenging to say the least. But, one must do what you have to do...but then again, you may luck up and find a replacement. Even then, I would machine a piece of stock on the mill and see if it couldn't be straightened...but I like a challenge! Good luck!

- 22 replies

-

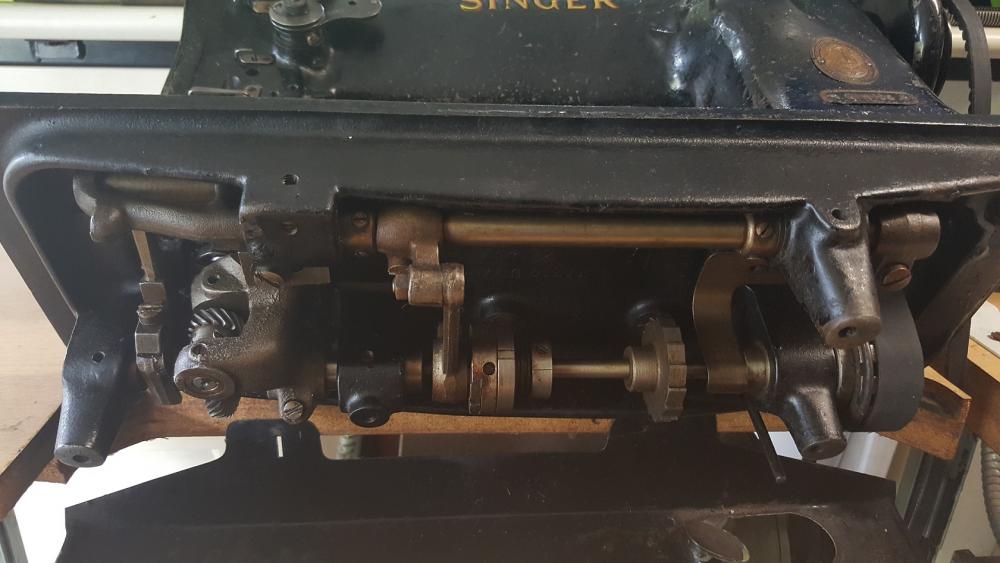

@dikman..thanks...seems in good condition overall, I would think normal use through the years...definitely not one of these we see that is just a pile of rust...missing half the parts. Seller relayed it was a family members machine...found in a shed! Oddly, the only rust is wear the leather belt sat on the pulleys for so long and a bit on the treadle..flat surface for things to settle. Overall, am pleased to own it! I was thinking of painting it but the more I look at it, the original paint is in good condition, so will keep it as is...

-

I have already downloaded the manual and parts lists, usually the first thing that I do and have read your resto thread on your machine...turned out very nice! I will look on the 'bay' but hard to know if any of the 'new' parts are going to fit without some sort of finaggling...might just be trial and error. I would have to check to see what shipping would be from across the pond...if it is reasonable, then may do it. Hopefully one of the vendors on here may have the parts. I will start with replacing the bell crank lever (part #82167), which is usually the culprit but understandably, it could be a combination of things leading to poor stitch length. Once I get it torn down, I will have a better understanding of what needs to be replaced. Thanks for the insight Constabulary!

-

Treadle...which I sewed with before removing the machine head from the stand. Love these old machines!!!

-

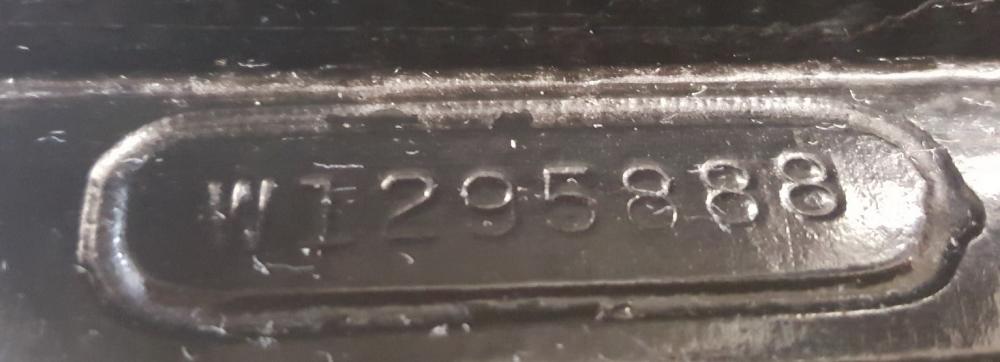

The title says it all and I couldn't resist! Overall it is in good cosmetic condition and seems to have been looked after properly. It is worn, like so many these days, only gets 8 SPI...oh well, I mainly bought it to save it and to one day use it for it's intended purpose. Nothing time and money can't fix, right!!! Plans are to disassemble, clean, oil, order parts to get the SPI back to as close to normal as I can...then use it ...within it's limits. The only part I see missing is the spring for the darning tension disk...I just may have and extra that might work! I do have a pair of boots that I need to fix, so that might be it's first project! Might touch up the treadle a bit to make it look better and fab up a flatbed table for it. Overall, just keep it looking as it does now...given that this one dates to 1962, it isn't THAT old! I will post a picture later of the contents of the drawer...I should never run out of needles!! Just a quick glance, I counted over 60 29-4 needles, new in their little envelopes...and even more in other packaging. Just thought I would share!

-

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

Oh yes, the dreaded clutch motor...a bit to much for me. I find that a small foam ball under the pedal usually will give me the control that I am after when it comes to my 111. I have redesigned the table for my 105-64 and after I finish my DC motor, I will adapt it to the 105 for it's trial run. I think it will work just fine, with a dial control to limit the speed on the cylinder arm machine without the use of a reducer. And not to mention, the ease of using a modern electric pedal to keep both hands free for sewing! I will post an update as things progress..although slowly due to work, school, and other pressing projects! V/r, Chayse -

@Davidmadd..is it possible for you to expand on the DC motor a bit more. I have finished up my plans and had my circuits double checked by an electrical engineer just to get another point of view, now I am just waiting on one part to arrive! I know it is easy to just buy a new servo motor and do the swap but I like a challenge and I am only into it for $25.... Thanks in advance! V/r, Chayse

-

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

@mixmkr..Thanks! The pups need a place to run, so I must get this fence done...and summer is just around the corner! -

Just phenomenal support on this forum! That is the main reason I joined, everyone is willing to help!

-

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

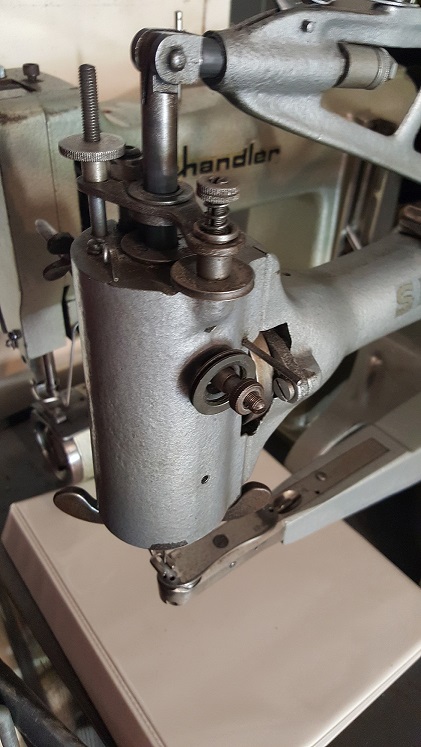

First and foremost, I would like to thank those that have given advice and insight to my latest machine! It is still in the garage and am sure it feels at home with the rest of the machinery but soon, I will move it inside to it's new location. I am not even going to attempt to learn on the machine with the current motor setup...I think it would be a wasted effort. I might as well wait until I buy a couple servo motors...one for the Chandler and one for the Singer 111W to even start the learning process. Not to mention it is a few steps back in the current 'To-Do' list that I have at the moment. In the meantime, I will source some new feet for the machine and stockpile them, as after my current project leaves, I can then concentrate on getting the machines setup and ready for my next project. Ahead of the machines is sitting in the garage, a 1996 Ford full size Bronco, my boss's truck from work. It was in dire straits and am almost complete before it heads of to get the interior lined and paint/body. That should buy me enough time to get room setup for the machines. On another note, my wife is ecstatic that I have finally completed my sewing machine inventory, thus focusing on her 'honey-do' list for me! I won't mention the fact that we just bought a house,I work a full-time job, and am a full-time college student...so in reality, I have Friday (after work), Saturday, and Sunday to try and slowly chip away at the things I need to get done! Needless to say, it keeps me busy but I wouldn't have it any other way! Thanks again and I will update as things progress!! V/r, Chayse -

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

Thanks @gottaknow, @CowboyBob, and @dikman...I am truly excited! If I would have had the funds and space...I would have bought them both! I can't wait to get started with these machines. Unfortunately, seeming that we just bought a house....certain 'honey-do's take precedence over my hobby. The biggest is getting the fence up for my rescue dogs....right now they have a 40ft x 100ft area to run. I have roughly 400 linear feet of fence to put up....and I am really not looking forward to it! But, they deserve the room and space to run...I will kindly take a backseat to them..just due to the fact that with their history, they deserve it. V/r, Chayse -

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

-

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

-

It followed me home....New to me Singer 111w

Chayse replied to Chayse's topic in Leather Sewing Machines

-

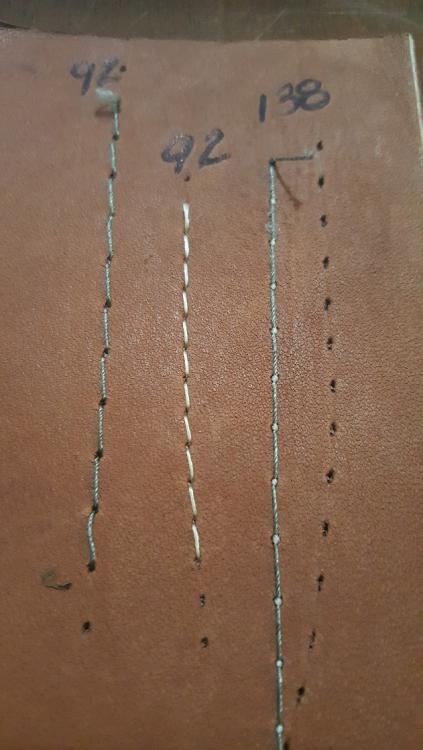

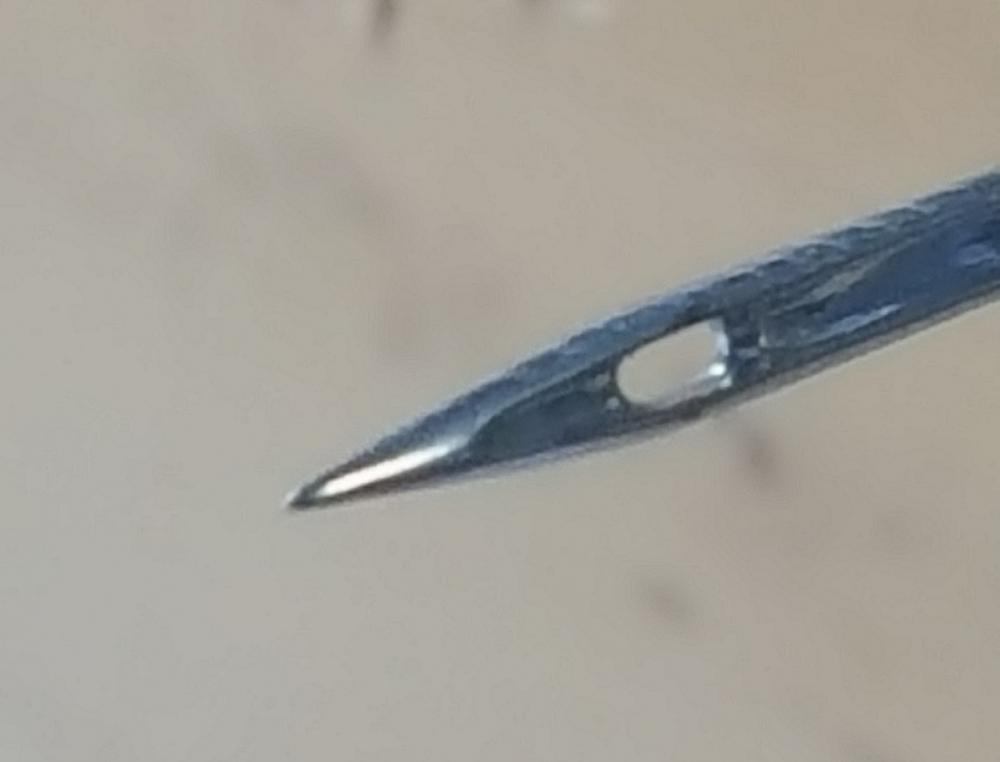

I took a short trip to go and 'test drive' the 2 Singers I had mentioned in my earlier thread. The owner of these machines was maybe 25 and had very little knowledge of either of the Singers. Story has it that the upholstery guy at their shop up and moved, leaving the 2 machines behind. The boss told him to get rid of them...so like any smart person, he took them home. And there they sat in the living room. I brought a couple of scraps with me from home...the only 3 scraps I had...some 1000D Cordura and some leather. Maybe you all can identify the leather, just a bag of cutoffs that you can buy at your local hobby store. I do not know the differences in leather yet...vegtan, etc. One of the machines was already threaded...not by the owner but the upholstery guy. The 211 had some #92, so I started there. The 211 sewed very nice on both the Cordura and the leather. I will admit that I had a hard time with controlling the clutch motor...a HUGE factory Singer clutch motor! I didn't bother to look at what HP or rpm that thing was ...all I know is that it was FAST!! Everything operated just fine with no issues noted. So then I moved on to the 111...it was not threaded! I tried my best to remember how to thread this thing...I probably watched 30 videos last night on both of the machines. The 2 threads available on the stand were #92 and # 138, both UVR thread. I started with the 92 and had no issues...except for proper control of the clutch motor!. I forgot to bring one of my dogs squishy balls with me to put under the pedal...ugh! I then removed the 92 and threaded the 138...again..probably wrong! I did notice the tension was off and you can see in the below pics, the top tension is to tight. Overall, other than the tension, the machine had no issues. I will add that I have no idea what thread was on the bobbin of either machine. I scoured the machine for flaws, wiggled things, moved the needlebar, rocked the handwheel for play...you name it. To a total novice like myself, it seemed fine. I paid the man our agreed price, $280, and he helped me load it. I will include some pictures below...and I am excited to have this machine! It did come with 62 new needles (i counted them..LOL), and 4 bobbins. Looking at the needles, they are marked "Indor 110", I believe they are size 18? For that matter, I do not even know if they a for leather or marine canvas...haven't researched them yet. As of now, the machine is in the garage until I can make a bit of room in the spare bedroom..... Thanks to everyone for their advice and insight on the two machines, I think I made a good choice but only time will tell. V/r, Chayse Some more pics...

-

Well, I will be getting up bright and early to make the 2 hour trip to test drive the 2 Singers! I have been reading and trying to educate myself on both machines, as the seller has no idea on either of them. Oddly enough, a Consew 206rb popped up today...has been listed for quite sometime and the seller lowered the price today...$400...head only. I have messaged the seller for pics and to see if the machine can be demo'd before purchase. Should either of these machines have faults or not sew, I might have a back up...but all in all, I know it is a crap shoot these days. Understandably, I know the Consew is the same machine....but with reverse and different stitch length adjustment. I will update should one of these machines follow me home.... I would like to thank all of the members of this forum for the advice I have received thus far, not only on this topic, but each and every time I post. I sat today and read probably 50 pages of threads while the repairman was working on my microwave..helped pass the time and I am continuing to learn about all of these wonderful machines. V/r, Chayse

-

I am not opposed to not having reverse.....I sorta compare that to my lathe...bare with me here for a moment...I have many hobbies, one of which is metal working. I currently own a lathe that dates back to the 40's...bare bones, no frills! I specifically bought the machine to learn, thinking if I can learn and create my projects on a dinosaur like that, the possibilities are endless if I move on to the new fandangled lathes that are produced today. I am, by no means, an expert when it comes to sewing. My mother taught us all to sew, on home sewing machines...which I do own. I am comfortable with hand/eye/foot coordination...as I have to do when tig welding. I would agree a servo motor would be in-store but think I can make do for the time being...sorta like tig welding...more pressure=more power/heat into the work piece. On another note, the Pfaff seems outta reach, seller has other plans. So, guess it comes down to the Singers! the 111W being older, of course, but both walking foot...AND I can demo both, as it is the same seller. I will add that I appreciate the clarification from Uwe about the Pfaff parts being affordable, guess it is really not a consideration now that the seller has changed plans. I greatly appreciate the info thus far, the more I can learn, the better! Please keep the info coming. I have downloaded both manuals and am comparing the 2...guess it comes down to what Uwe previously stated....it is what I feel comfortable with...a very true statement! V/r, Chayse

-

Thanks @dikman & @Uwe for the advice....I think either of the machines would fill the 'gap' that I have....Currently I have a Singer 20U33( for light/non-leather stuff) and at the opposite end of the spectrum is my Chandler 305-64 (Heavier stuff..highly doubt I will ever test the limits of this machine). Just in the back of my mind I feel a bit 'uneasy' about the Pfaff...used in a shop for canvas and auto upholstery. Either way, here are some pics....

-

Since missing out on the Pfaff 545H4, i have been looking for something within my budget...again! I have stumbled across the 2 machines...well 3 actually. 2 Singers and another Pfaff. Here are the models.. Singer 211G165 Singer 111W155 Pfaff 145H3 I have read plenty on here and imagine either would work for my needs (light/med. leather sewing). Singer parts seem somewhat available and reasonably priced, should something go wrong. What scares me about the Pfaff is the high $$$ for proprietary Pfaff parts. I am leaning towards the Singer 211G but honestly...i am unsure. All 3 machines are the same price, individually($300), just need some guidance of the experienced folks here! V/,r Chayse

-

Well... I am going to try and be reserved here....seller ended up selling the machine while i was driving to go see it....all for a 'mere $25 difference in price! Needless to say...I hate greedy people! Strong I know, but really...for $25! Ugh....oh well, I have 2 others at home that do what I want to do... I guess I just need to stay off the local for sale boards...CL...Letgo...etc.. The search will continue...I am hooked....we shall see how many machines I can acquire (or how many machines my wife will let me have)..........

-

@shoepatcher..thanks for the info...I searched again last night and found some more information. I am going to look at the machine tonight, it is in a home setting and the woman can no longer use due to her age. I just wanted some preliminary information before I go to see if this will work for me. I am taking some samples to sew and check to see if there is any excess play in the machine. We shall see...the price is right, so wish me luck! I will update if it happens to follow me home.

-

I think Yetibelle was referring to having a machine with potential to do much more that what you are currently using it for...in this case, your wallets. I will throw my $.02 in here, understandably you are sewing wallets now and are looking for a capable machine. If you buy a machine that will sew your wallets and maybe not much more (thicker leather), and you then decide to take on another project that requires you to sew that thicker leather, you are now not able to take on the project due to the limitations of your current machine. I am sure others will lend you their expert advice when it comes to all of the different machines and their capabilities. I personally have two...one for light to medium weight leather and one for the thicker, heavier weight leather. I digress.... Good luck and am sure someone here will help clear things up for you! Chayse

-

I have a quick query for those of you that are familiar with the Pfaff 545-H4-06/01-CLPMN.....what are the sewing limitations with this machine when it comes to leather? I did search the forum but after about 20 or so pages of threads with "Pfaff 545"...I folded! Just looking for min/max ounce of leather that this machine will be happy sewing. I am not looking at anything too thick, as I could just use my Chandler 305 for anything else. I will sit down and figure out min-max thread size and needle sizes later. Thanks in advance!! V/r, Chayse

-

For a first, that is excellent....I actually thought it was a reverse of your avatar! We are our own worst critic, able to pick apart every minor flaw...reason being...we just spent countless hours over the project until completion. I think it looks great and from a novice like myself, I am in no position to 'critique' your work. Standing as a 'third-party' I see it as intricately detailed.... Point being...I am a welder...although not by trade, and every weld bead I lay down is my signature...I am able to pick out every flaw that may be present because I just spent countless hours prepping, grinding, and welding. To the 'layperson' they see it as a job well done....something that they have come to YOU to get finished or to purchase. We all are learning, even if we are considered a pro at what we do. I, myself, would be glad to own something like this if this is something that I like....why....because it is very nicely done! Be proud of what you have accomplished and if you happen to notice a flaw...learn from it! V/r Chayse

.thumb.jpg.5af4d123333409eb6d51c4415d8fc781.jpg)