Chayse

Members-

Posts

127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chayse

-

@dikman...my lathe is the only thing that I changed the color on....ALL the rest of my machinery....yep,,,Machine Gray! I completely disassembled and stripped the lathe, hence why I changed the color. My other tools are far too complex and would be very time consuming to strip and repaint! I like your idea of an old singer painted a non-factory color...add a little chrome....I think it would be beautiful (as well as functional). Maybe one day once I catch up on all my projects!

-

@jimi..thanks for the info...I think this satisfied my curiosity.. More often than not, I get squirreled off on something like this...old iron with no model numbers, etc, guess it is the thrill to try and identify things. I am not in the market for another machine at the moment, so just wanted to see what the consensus of the experienced members on this board had to say. Personally, if I did have it, although probably sacrilegious, I would strip the machine and paint it a 'unique' color. I do like the black and although not a purist, sometimes I think it is a bit boring. Have a couple bits re-chromed and I think it would be a beautiful, unique machine. At the minimum...a definite conversation piece. Here is an example, although some may not agree...my 1946 Atlas Metal Lathe (Resto-mod project)...it was a complete basket case when I bought it. It is now almost complete, lacking the DC motor conversion and a few other bits. When manufactured, most..if not all, were painted 'Machine Gray'....I thought it was a bit boring. I digress.....

-

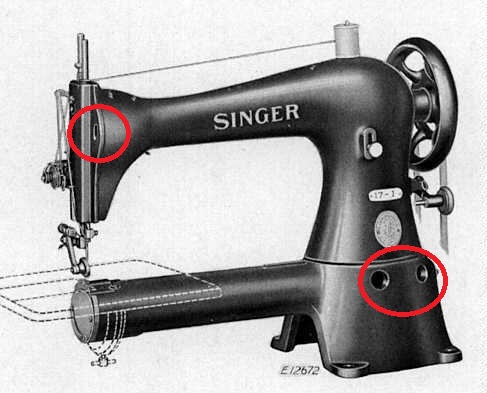

@Constabulary..thanks for the info....looking through the 17 Class machines...this is the class that closely resembles the machine in the pics. I knew the treadle table was wrong in the pics...seeming that the machine is not even bolted down and the mounting holes do not line up. @jimi..I cannot find a pic of the model of machines you listed.... I surmise that it is most likely a 17-1 due to matching things I found in the pic... 1. The oval hole on the left of the machine....on most of the other 17 Class machines, this hole is round. 2. The shape of the actual cylinder arm also is somewhat different on some of the 17 Class machines 3. On most of the 17 Class machines, there is a round whole on the front of the machine head...where this is one of the only 17 Class machines without a hole on the head. This is the link ( http://www.industrialsewmachine.com/webdoc1/used/used-singers/17.htm ) where I compared the pics of what I found against what is listed. I understand that this is only one reference and actually one of the very few that actually showed pictures of the different models. This is mainly out of sheer curiosity at this point, as the machine is listed on the local CL. If I wanted to get the machine...out of pure curiosity sake, I can pick it up for about $225. I mainly like the look of the machine and table....that 'old iron' look that so many things lack these days. Thanks for the info!! V/r, Chayse

-

-

-

Enlisting the help of the folks here on identifying this machine. I have looked via google....but mainly focusing on the 2 holes adjacent the arm itself....it sorta resembles a 17-23 but I am not for sure. What say ye wise ones of LW?

-

@gottaknow- Thanks for the info...still on the fence about this machine...

-

@gottaknow..can the cam be swapped out to make this machine a 42 stitch machine? If so, how expensive is the cam and presser feet? Thanks in advance.

-

@patria--thanks for the insight...I just happen to know a fellow down the street with a shop that has been in business for 40 years! He works on them all...from home to industrials ...but hopefully I will not need him. I may go see the machine this weekend but must go and celebrate my father's 75th birthday first....I owe it to both my mother (for teaching me how to sew) and my father (for teaching me to work with my hands at a young age) for what I am able to do today! Thanks again for all of the info provided. If I pick up the machine, I will surely keep everyone updated. V/r, Chayse

-

@Dirtscraper-I am in the same boat as you and thus far this forum is absolutely a great place....filled with a whole bunch of knowledgeable folks that are willing to help. Don't be afraid to ask questions, to me, that is the first step in learning something new. Welcome to the forum! V/r, Chayse

-

@gottaknow...I am skeptical as well, I figure I would go look at the machine and see if it functions as it should and the stitches are tight. I appreciate all of the input...I definitely know more than I did when I started! I have a few questions for the seller and he has not replied, as of yet, so will see what he/she has to say. I would more than likely use it for sewing nylon strapping and such...leashes, dog collars, etc. or anything else that i feel compelled to tack....

-

@gottaknow...thanks for the indepth info on the machine! If i go look at the machine, anything special i should pay attention to...besides the machine stitching properly/stitch quality?

-

-

Those cams can get expensive to change things up....I guess these would be considered a 'niche' type machine....Thanks JT for your input

-

i have researched the limitations of the machine....it is designed to do one thing and one stitch. I guess if I wanted to produce some nylon dog collars and leashes pretty quick, it would work like a champ. Understandably, I know this has nothing to do with leather or leather working...I am just looking for opinions solely based on the machine, I guess. I know Juki is a reputable brand in the business, however, I think I would tend to lean toward the older...all metal versions compared to the mass produced machines they make today....there is just something about metal parts that scream longevity! I know this thread will get more views than responses but I was just inquiring with all of the knowledgeable folks on here, as I lack the sufficient knowledge when it comes to this....this is just one of those occasions where the collective knowledge base of this forum applies. Thanks Chayse

-

Thanks patria...it is intriguing because I do work with nylon, not only leather. Hmm...it is tempting, just solely on the price point alone. With talking with the owner, he bought the machine for a project...now he is moving on...at $400, compared to the price of a new machine, if it works as advertised, it may be worth the purchase. The machine is only 8 months old....all this info is solely provided by the owner, as I can not verify.... The price includes factory table and motor also....which is 110v, which is also an added benefit for me.

-

I Know that this may not be a 'Leather Sewing' machine and may not belong in this section...mods, feel free to move...just looking for honest info..... Here is question....would it sew leather...it can run 92 thread...? If so, what possible ounce or what possible function would it have on a leather project, if any? Thanks!! V/r, Chayse

-

Need some advice and opinions please...I have a chance to pick up a one owner Juki LK 1852, 28 stitch bar tacker for a VERY good price....what say you ole wise ones of this forum? I know that it is designed to sew one stitch and it has one purpose....I am intrigued? Thoughts, opinions, criticism welcome... V/r, Chayse

-

Suzelle, I have a gold original singer industrial that is made in Japan. I haven't really researched the serial number to find when it was manufactured at all. I mainly use v69 when sewing my cordura...I believe I watched a video somewhere that showed whomever sewing with 92. I will see if I can dig up some more information on thread use...I am curious myself...

-

@dikman...yes, I would agree, it is fun and I do enjoy a good challenge! This isn't new to me....I have rebuilt my 1946 Atlas lathe, 1938 Atlas drill press....and although it took me 5 years, a frame off resto-mod of my 1978 Toyota Land Cruiser. Currently, I am redoing a '96 Ford Bronco for a friend...in the wings is my '80 1st generation Toyota pickup. All in do time...as we have plenty of it... I do like seeing the end result...a functional machine that you have helped to rebuild, giving it yet another breathe of life. I am sure my boys will probably hate me when it comes to getting rid of things when I can no longer do what I love to do. But until then, I will continue to do what gives me peace and joy...working on such things that hopefully, will give some one else joy...and...of importance, saving a vintage machine from being recycled into things we know today....junk! Nothing is built like it was in times past. If I can save just one from the scrap heap...then I have done my job... Thanks again to all that have provided information and insight...without one another...well...we would be clueless I think! V,r Chayse

-

Here is my .02.....if you want to keep the old time look, at least do a re-wire...bring it up-to-date. You can still keep the motor, but for safety sake, just update the wiring to what we use today. There is nothing wrong with using the old motor...I have a period-age motor on my 1938 Atlas Drill Press....but I did use new wire for the motor..I was able to keep the 'look' of a vintage machine without losing sleep if you happen to leave it plugged in by mistake. V/r, Chayse

-

Suzelle, It is definitely manageable to remove out of the table! I use mine for sewing 500D and 1000D Cordura nylon for projects...I am actually going to use this machine to sew up a replacement interior for my truck, as the cloth is starting to get thin. I will be using the Cordura with v69 thread and size 18 needle. V/r, Chayse

-

That sounds about right...I watched the video Uwe posted on threading the Adler 205-370...I 'believe' they may be similar. And yes, it would be 1.5 times around. I love his videos....mesmerizing to say the least!

-

Thanks Constabulary! I just dug through the manual, a 5 language version that was available on the Durkhoff Blog... I 'think' I may have figured it out..what was confusing me was the dual tension assembly on the machine....I am just using one set of the discs, instead of both... You were pretty spot on in your post above, however, I did read that the thread should wrap twice around the thread tensioner.... I wish I could copy and paste and apologize if this is confusing....but all I have is just a scanned copy. I will attach to see if they are able to be opened.. Threading.oxps