Chayse

Members-

Posts

127 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chayse

-

Thanks! I am in the process of refurbing the table now, as whomever cut the end off the table. I plan to move the motor control pedal out from under the machine to a more practical location. As for the foot left pedal, it will be close by in a comfortable location. The tension assembly is like we put it together yesterday at the shop and will adjust accordingly when finally setting up the machine to sew. The owner handed me a couple different springs for the tension assembly, in different weights, to help in getting things dialed in...but that is a long way off. I still have to sand/stain the top and get it mounted. Then I will focus on designing the foot control bracketry...just time, steel, and a welder at that point. All of which I have, will just have to find the time in between the rest of my 'projects'! I appreciate all of the helpful advice that everyone has provided thus far...one of the reasons why I finally joined this group! V/r, Chayse

-

Thanks but I have a steep learning curve to overcome on this one...I think the fun and frustration, are just around the corner!

-

I figured I would start a new 'thread'...no pun intended! I am in need of some assistance with threading my machine. I do have the manual, although a bit confused. The manual covers the 104 and 105 series but what is confusing, the 104 looks to be a 2-needle machine. Do I follow the threading procedures for a 2-needle machine even though mine is only using one? Does it thread like the 205-64, looks as if they are roughly the same, although the 205 has a walking foot? I will revisit the manual and study it a bit harder...right now the coffee hasn't kicked in and am just a bit confused about it. Thanks in advance! V/r, Chayse

-

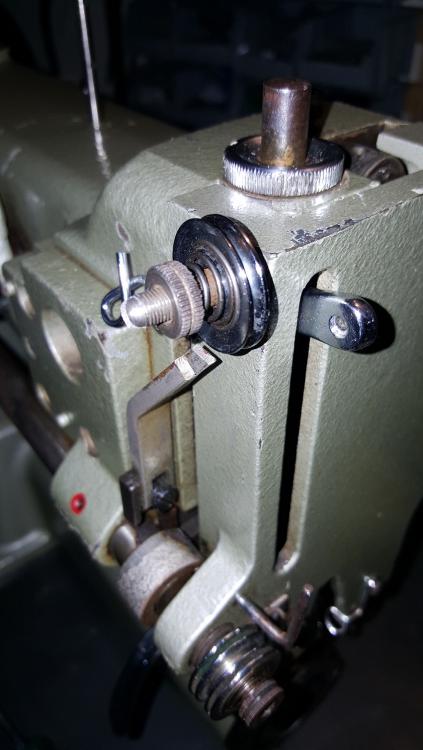

Here are a couple pics of the parts. I will continue to let the tension assembly cure before I utilize it...also, the tension release bar (I am sure not the proper name for it), works as designed.

-

Well, after about 3 hours at my friends sew repair shop, I was able to find a thread reel pin and tension assembly...plus other goodies for my 20U33. The thread reel pin was free and we dug through bins and parts drawers and were able to come up with a tension assembly that will work. However, we were unable to find the right thread pitch that would fit the 305. So, out came the micrometers and drill bits. Unfortunately, I had to use JB Weld to secure the new assembly in place (currently curing). On a good note, it didn't cost me but just a couple dollars. I spent a total of $83 dollars today....most of which went towards a binder attachment ,edge guide, and various parts for my 20U...as I sew a lot of 1000D Cordura Nylon. The actual money spent on the 305 was .....really...not much! We were able to find a roller guide for the 305, as well. Since I plan to make a removable tabletop for the 305, I will be able to mount the roller guide in an acceptable position....although not in the factory position...if that makes any sense. The roller guide is for an older Singer machine, so once the tabletop is in place, drilled and tapped, I can mount an use the roller guide....it costs me a whole $7.50! Also, I had to order some needles for the machine..the owner's supplier only sells the needles in lots of 100. So, to lessen the cost, he agreed to pay half of the cost...just so he could have some on hand if a potential customer should need them. So, I was able to procure 50 needles for my machine...should honestly last me a lifetime! This guy has parts galore...hanging on pegboard...in drawers....in nooks and crannies....geez...I really don't think there is a machine that he has not seen (within reason). He did pull out a shuttle assembly for a big cylinder arm machine....it was almost twice the size of the one for my 305...it actually made it look small! He then pointed to the door where the motor laid....was a 1.5hp factory motor for the machine! He said it was for a machine similar to mine but it had been so long that he couldn't recall the manufacturer. Absolutely love places like this....and to make things better...it is just right down the street from my house. It was a good day....well, until I came home to find the A/C was acting up....that is another story! V/r, Chayse

-

Ok, I was successful in removing the broken tension assembly stud...man what a P.I.A. that was.... Now just to locate the replacement parts. I searched on the Goldstar website, as JimTimber recommended but was unable to locate any parts....maybe I am not searching 'correctly'. If anyone has any words of wisdom on the website, let me know...I am on my way to a friends sew shop, as his father has been repairing for a couple of decades....maybe I can get lucky and find some parts in the junk drawer! Wish me luck!

-

@Constabulary-I think i am tracking now...will investigate a little further about the missing tension assembly @JimTimber-Thanks for that link, I will do some searching to see if I can locate it @shoepatcher-it is threaded, 10-32 threads actually, I was able to remove the broken stub..you can see it in the last picture, I screwed it in a couple threads to prevent from losing it Thanks for everyone's help, now i will search for these parts... V/r, Chayse

-

May I please be granted access as well? Thanks in advance.

-

First holster attempt

Chayse replied to ToddMaine's topic in Gun Holsters, Rifle Slings and Knife Sheathes

We are always our own worst critic...and always will be! That looks great, from a newbie like me, and would be proud if that was the end result of my first holster! I can only wish that my first project turns out as good...I am totally new to all things leather, I am a certified welder/CNC machinist...so I have quite a learning curve to overcome when it comes to all of this.... Hats off to you fine sir! -

This was a private seller...guess he got the machines from work. The very same way I picked up my vertical mill, fellow was told by the boss to make the machine disappear, due to a fallout with a former employee...so he took it home. I actually passed on 2 lockstitch machines today....a Chandler (Brother) DB2-763-5 and a Singer Professional..owner is moving and needs the funds...$300 for both. Wife would have killed me...and I currently do not have room!

-

I couldn't pass it up....ad had a horrible picture and took me a couple hours to identify it....once I found out what it was capable of...I bought it. He also had a Consew 206rb for the same price but I was too late on that one....

-

@MADMAX22.. I have no idea what they would have used it for, there was, what seemed to be, a stiff, wire-like thread on the bobbin. I lucked out and picked it up for $250. My original plan was to clean it up and flip it but figure I would dabble in a few projects that my Singer 20U can't handle. I mainly sew Cordura nylon and such...so this is entirely a new beast for me to learn on!

-

Constabulary, I think we may be talking about 2 totally different things here. I just re-read what I posted and your replies. Here is a pic of what I discovered that was broken...the $97 piece from Durkoff. I refuse to pay absorbent prices for simplistic things! I will fabricate a new thread reel pin on my lathe or mill before I pay that...maybe for a more important piece...yes...this...no. Here is the part in question...

-

I actually grew up in Orlando, my father retired out of NTC Orlando when it was still open...maybe '85-ish. I do remember Epcot just being an open scaffold.. I am ok with change but it it is just getting..too..peopley..if that makes any sense.. @ChriJ ..dim is an understatement,,it sickens me sometimes...but...all I can do is try to save just one at a time.. Here is my thought...I will start with dog collars , and hopefully my skills will continue to progress. If I can send them to their new home with a new collar, a little piece of me, then I have done my job....I digress....back to leather talk

-

Either way, hopefully it helps you or someone else solve an issue or potential issue, you might be surprised, even today, many rod eyelets are still porcelain or ceramic. V/r, Chayse

-

Looks good...and welcome to the forum!

-

I don't know when you left but yes, on 192 and I-95, there is a CC..LOL! I was stationed at Patrick from 02-08, then went directly overseas as a contractor for 4 years working dogs. It has changed quite a bit since we moved here in '02. It is frustrating sometimes with these rescues...very hard to know the history behind these pups, so unless you do something that triggers a bad memory....it is a learning process for the both of us. We have had both ends of the spectrum...submissive to aggressive. Just got to be patient and show them you mean nothing but good. Love and patience goes along ways for these pups...soon, trust follows! Here is our first failure....2 y/o owner surrender...just "because he wasn't a German Shepard"...got to wonder about people these days!

-

Hi suzelle, I couldn't find anything in the owner/maintenance manual for weight of the machine. Without physically removing my 20U33 from the table, I would guess the head alone weighs approximately 20-25lbs. If you would like, I can remove the head and actually weigh it if need be? V/r, Chayse

-

Welcome to the forum! From one new member to another, this forum is filled with respectful and knowledgeable folks! I am sure they will help you solve any issues that you may encounter. V/r, Chayse

-

Just an idea, should the brass/bronze start to wear, you could probably modify an eye from a fishing pole to work...being a diehard Bass fisherman, I have some vintage rods from the 70's (my father's) that I still use today. They show no signs of wear and I strictly use PowerPro braided line. Just my .02 V/r, Chayse

-

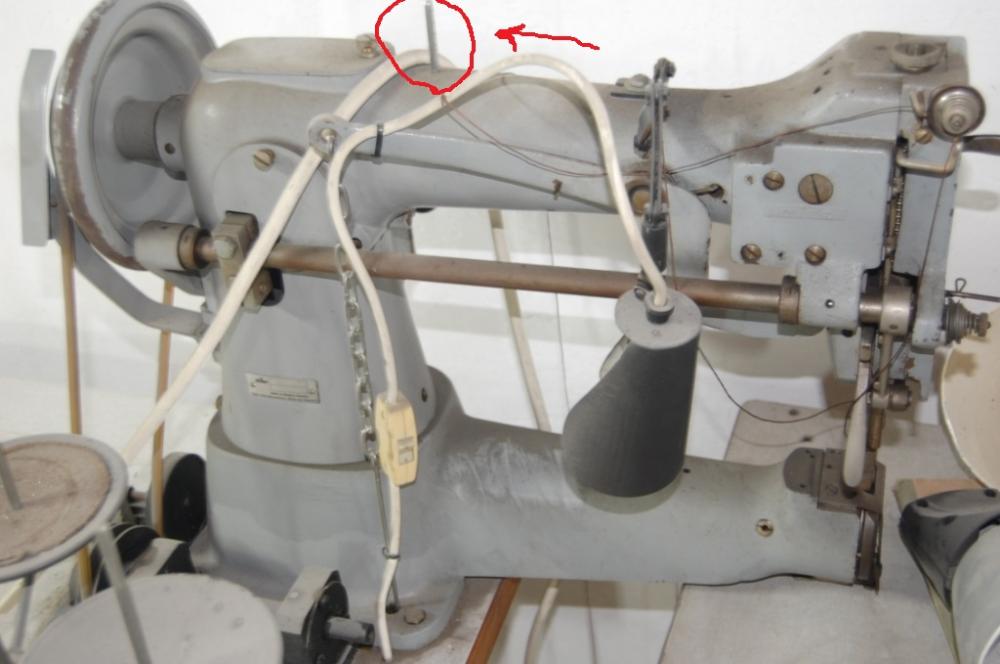

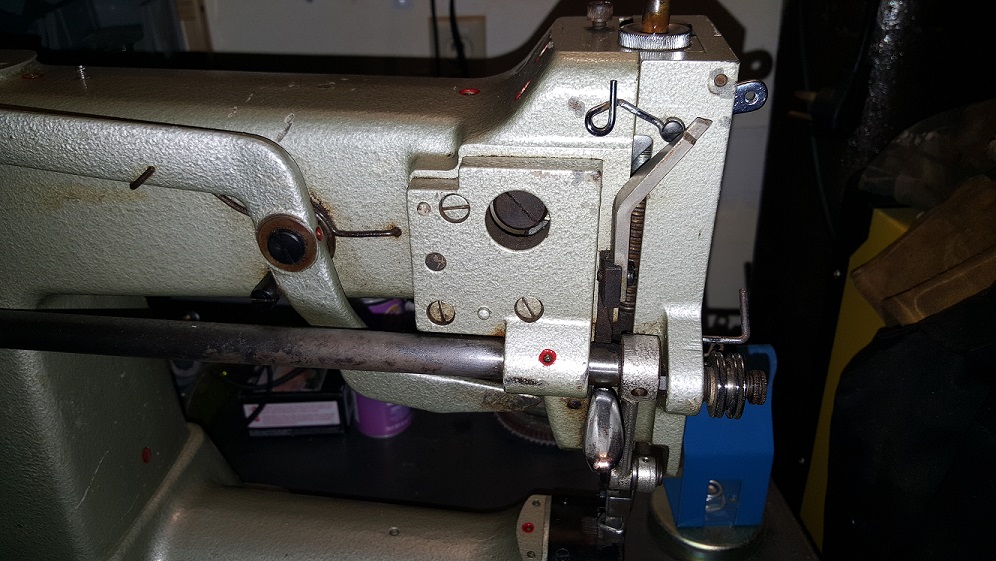

Looks like you are correct Constabulary, looks as if there are minor differences between the Adler 105-64 and my Chandler 'Clone'. The first picture is of an Adler, the second is my Chandler...looks as if the Adler has one more thread tension assembly than my Chandler. My machine is a needle feed machine, with reverse...the stitch length adjusted by the lever...which I think is similar to the Adler.

-

Yes, Belgians are not your average house pet... I brought home my partner from Iraq after working together for 4 years. I was used to the breed from my years in the military. He passed unexpectedly last year, it was devastating to my family, as my wife had grown very close to him. Instead of 'buying' another Mal, we both decided to foster and rescue...we have failed twice(adopted 2) but have since had the pleasure of placing 3 to new homes. They are challenging to say the least and takes a bit of patience and determination to handle them. That is probably the reason they end up on the street or in a shelter in the first place, sad! We just moved from Melbourne, picked up a nice parcel south with plenty of room for the dogs to run.

-

Thanks for the warm welcome and insight, once the Chandler is operational and properly sewing, I will definitely take my time. Thanks again!

-

Second post, so far I have learned a lot, just by lurking before I joined. So here is the scoop, I came across a Chandler 305-64, understandably just a re-badged Adler 105-64 ( I researched here before purchase). The machine is in great shape for being roughly 30 years old and I am the second owner of this machine in this time. The previous owner, the U.S. Navy, purchased the machine brand new in 1987 at a tune of $3721.00 (it has a brass placard on the back with all the information). As with all military hardware, it had a functional 'Hour Meter' attached to the table...showing only 465 hours....so 15.5 hours a year (average use) is not bad in my book. It is complete with table and the dreaded clutch motor. The only damage I found was that the thread reel pin on top of the machine was sheared off. It took me a few minutes with a small drill bit and an easy-out to remove the threaded stub. I contacted Durkopp Adler about a replacement...needless to say they are 'proud' of their parts!! At a cost of $97.00, I think I can fashion one up on my lathe and mill and have some change in my pocket afterwards! I am currently refurbishing the table, as it was stored in a warehouse and had not been taken care of at all. After a good cleaning and a bit of oil, it turned smooth as silk. I didn't have any sewing machine specific oil on hand, so I oiled it with some oil that I use on my vertical mill, oil that is used for the precision ground matched bearings in the mill. I figured if it was good enough for precision bearings, it ought to be good enough for a German-engineered machine....please correct me if I am wrong? I will pick up some oil specifically made for sewing machines. I came with only one foot, looks like a right cording foot and have contacted Bob at Toledo Indust. Sewing Machines for replacements...at least he has a regular foot in stock and should get me started in the right direction.I have a line on a servo motor to replace the clutch motor but will wait until I finish the table refurb until I purchase it. Being new to leather, I have a few projects lined up, mainly dog collars, as we foster and rescue Belgian Malinois. I would like to be able to send them to their new home with a piece of me...a new collar as they settle in to their new homes. I may dabble in a holster here or there if my skills progress to the point I am not wasting material. So, experienced members, if you could possibly shed any light on the pros and cons of this machine,it would be greatly appreciated. Seeming that I mainly use my Singer 20U for most of my projects, the fan-dangled cylinder arm machines are all a new beast to me! Any help, words of wisdom, or criticism is greatly appreciated. Here are a few pics after moving it into the sewing room. Thanks in advance. V/r, Chayse Another angle

-

Hello all, thought I would introduce myself..I am a newbie to the world of leather but not to sewing. My mother taught all of us children how to sew at an early age...I just stuck with it. My main hobbies include everything metal...I am a certified welder and I am graduating from CNC Machinist school next month. although I am just a desk jockey through the week. I currently own two machines...a singer 20U33 and the new addition, a Chandler 305-64. I am interested in leather and the art of leathercraft...I am one who enjoys working with my hands and seeing the fruits of my labor when finished. I do have a couple of projects lined up once the rehab of the Chandler table is complete. I will mainly meddle in a few holsters and concentrate on dog collars, as we currently foster and rescue Belgian Malinois dogs...I was a former dog trainer in the military and carried it through to my civilian job for a few years. I have already learned a lot here on this forum when I lurked...it simply amazes me what one can do with leather. I am looking forward to learning and expanding my knowledge base in this craft! V/r, Chayse