DavidRM

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Location

Beaverton, OR

-

Interests

leatherwork, tooling, pyrography, bags

LW Info

-

Interested in learning about

sewting

-

How did you find leatherworker.net?

searching for something about sewing

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

DavidRM's Achievements

Member (2/4)

-

I am interested in a Bell Skiver. Willing to drive 120 miles or there about (from Lehi Utah) to pickup.

-

I was looking through my old tools and comparing a few things and I noticed that Craftool reused the number 445. I have an old Craftool 445 marked Craftool Co 445. The current Craftool D445 is a serpentine stamp. The old Craftool 445 is like a large Craftool Co USA C 431 1 (not the same as a C 431). Did Craftool reuse many of their old numbers for new tools? Just curious.

-

Thanks all. Yes, the best solution is sunlight - but long days of summer are gone and I could not get much color change in one day of sunlight here in Northern Oregon. The airbrush solution I think would be best- another motivation for me to learn to use one! I like the Dieselpunk.ro suggestion but I didn't see this until after I was done - I tested this on a small piece of scrap using denim instead of felt - I may use this technique in a future project just for the color variation effect (although it leaves some wax on which would affect any finish application afterwards). I didn't want a worn look - just the color change so I didn't try the boiling water. I discovered I had some light brown leather dye in the back of my cabinet that I had forgotten about and I used that. I really appreciate all the suggestions! I made multiple attempts to upload a photo - I kept editing the photo to lower resolution After I got the file size down to 871KB and I kept getting complaints about 1.46MB being the maximum file size - I gave up. If I figure it out some day - I will upload to share.

-

I am making new handles for a bag/purse made from vegetable tanned leather. The bag is probably as old as me - so I will clean it and oil it. New veg tan handles will be much brighter than the older leather bag. The lady I am doing this for will be happy just to have handles that function again. However, I would like the handles to match a little bit better. I suppose I could attempt to dye it slightly darker to match - but that could take a long time to figure out the right thinning for the dye I currently have. Is there a particular dye someone could recommend or any trick to getting veg tan leather to naturally darken quicker? Thanks for any ideas

-

I have made a few knife sheaths that turned out well. These have been fitted without a significant guard on the knife. I am making my first knife sheath for a knife with a significant guard so I will need to add a fastening strap to the sheath. I am thinking about placing a snap above the bottom (blade edge) guard and running the strap over the handle to the snap. The image of Stohlman's sheath the strap begins where I would place the snap and ends at the center of the sheath over the knife blade. I know some folks don't like the snap end facing towards the front of the knife - easy for the strap to get caught during normal forward movement. I see many knives use a center snap - in the fashion that Stohlman recommends against so even though Stohlman recommends against this many knife sheaths are made this way. I don't see any sheaths with a snap above the back guard and a strap running to it - like I am thinking about doing. I am sure someone else considered this - Can someone explain the reason for this? Yes, I would have to extend the knife sheath back further to allow space for the snap - that should not be a problem though?

-

Tandy Neat Lac

DavidRM replied to cord1974's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

I tried the new neat lac the other week. I had the same experience. It reminded me of Resolene. I like it a little better than Resolene as I find Resolene bubbles or streaks too easily and works best if sprayed. I think the new Neat Lac applied better with an applicator than Resolene does - but the end result looked very similar to me. I am assuming that the new Neat Lac is an acrylic as it looks like one - but I don't find any documentation on Tandy site stating as much. In general I use Tan Kote most often and will probably continue to do so. When I want an acrylic finish though - I would consider the new Neat Lac over Resolene. I have some Angelus acrylic finish and I should compare it to that sometime. The new Neat Lac may have its place - but not as a replacement to the old Neat Lac. -

40W Chinese Laser - Engrave and Cut Leather - Discuss

DavidRM replied to Billy Hell's topic in 3D Printers and Lasers

I would very much like to hear what you ended up getting and how it has worked. Other than the small work area - were you pleased with the NEJE JZ-5? It has a low powered laser - so you must have been using it for engraving rather than cutting. Did it engrave well on vegetable tanned leather? Would you have been happy with it if it just had a larger work area? It seems most folks spend $4K - 12K for a good laser cutting/engraving system. My current interest is in engraving on vegetable tanned leather - I want a fairly large engraving mat size though. I am looking at other options with 500mw lasers - and wondered how well they would do at engraving on veg tanned leather. Someday I may find the funds to get a really nice system. -

Thanks for the suggestions. When I spray there is no problem - sparying seems to be quite popular. I watched the Don Gonzales video on antiqueing. When he goes over with the final coat of Tan Kote it lifts off some of the antiqueing - which he likes. So if I am going to apply a final coat by applying with a pad or dauber it seems I must be prepared for lifting some of the antiqueing. If antique is lifting antiqueing - there can be smearing - which was my problem. So I must be prepared for it and do it smoothly and rub appropriately. Tan Kote allows for more rubbing to get everything even (Resolene only allows for a couple of swipes) - so I will either switch to Tan Kote for finish over the antiqueing or go with spraying. Thanks. I will check out more of Don Gonzales videos - thanks for the suggestion. Not all youtube videos are worthwhile - his look good.

-

I am fairly new to antiqueing. I am using Fiebings Medium Brown Antique Finish. I am pleased with the results after I apply and wipe off the antique gel. I have problems when I apply a finish over it. The first time I used Fiebings Resoline and it smeared the antiquing around and ruined one piece of the project (I had to redo that piece). I completed that project by spraying the resolene on after antiqueing. I thought maybe I didn't let the antiqueing dry long enough so this time I let it dry a week - then I applied resoline to a test section and once again the antiqueing smears when applying resolene :(. Is the solution to always spray the finish coat over the antiqueing? (I don't really like spraying but if this is the solution ok, I can do it). Is the problem Resolene? Would tan kote or RTC smear the antiqueing the same as resolene (the Tan Kote bottle says it can be applied over antiqueing)? I picked up some RTC this last Friday and haven't tried it yet, but want to try it on a future project. Anyway is there any finish I can apply directly after antiqueing other than spraying? I wanted to ask before I test every possible combination myself Thanks

-

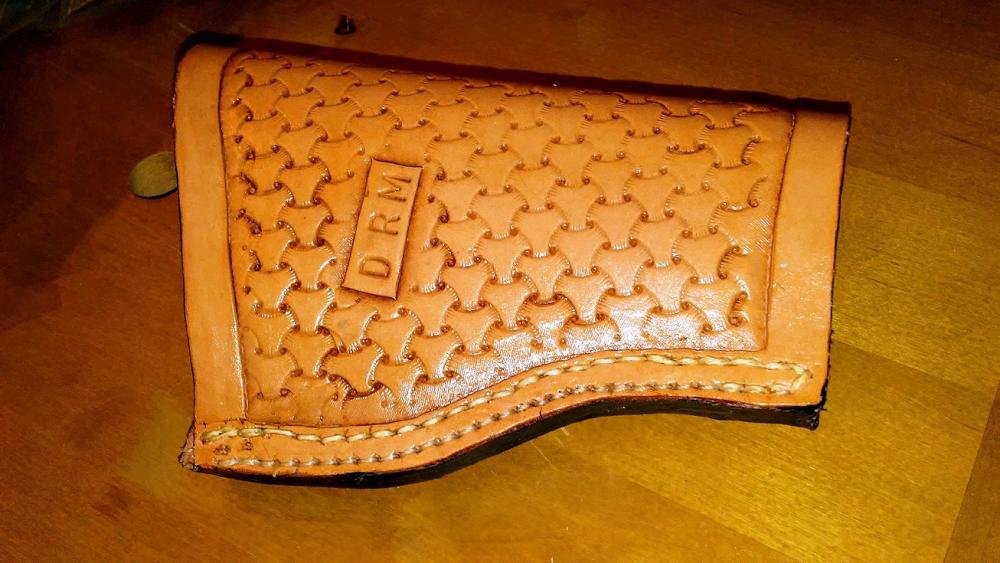

I completed my first holster. I look forward to the next one. Overall it fits pretty well. I made the mistake of attempting to sew this on my sewing machine - 3 layers of 9oz leather- that wasn't a good idea. After I mangled it up I finished sewing it by hand.

-

OK - these swing down edge guides look very nice to me. I am not going to drill and tap in my sewing machine. My sewing machine is not listed as one of those for which they are compatible. I looked at the back of my sewing machine (Consew 206RB) and there is a hole there -but it seems two holes are required to mount it and the holes on the back of my machine seem too far apart? The presser foot may hit it but there is slack there so maybe that wouldn't matter?

-

which to choose Consew 206RB or Chandler 67?

DavidRM replied to DavidRM's topic in Leather Sewing Machines

OK - I purchased the Consew 206RB-4. It sews nice even stitches and is well adjusted. I tried it with the original clutch motor. I didn't like the humming. I went for the new servo motor. Regardless of motors there will be a learning curve for me - so I will get to learn. I think I will learn faster with the servo motor. It should serve me well. I should post a photo of some projects I did before I got the machine and then in the future something I make with the machine. Oh yes and when we had to carry the table upstairs I was very glad to have the lighter servo motor on the table. Thanks for the input from all.- 7 replies

-

- sewingmachine

- consew

-

(and 1 more)

Tagged with:

-

which to choose Consew 206RB or Chandler 67?

DavidRM replied to DavidRM's topic in Leather Sewing Machines

The seller, a sewing machine mechanic, says the consew 206RB-4 it was built in Japan by seiko and that the current 206rb-5s are built in China. It is well used but either well maintained or refurbished. Sounds like the consew is a good way to go - and should be easier to get parts for it. It currently has the original low speed (1725RPM) clutch motor, but he would put in a new FESM-550C servo motor for a little more. I get the impression that many like servo motors (especially with speed reducing belt system), but it doesn't seem there is anything wrong with clutch motors if you have the right feel for it? My use will be veg tanned leather - often about 3/16" thick, but 5/16 will not be uncommon for me to sew - so I want something that can take it. I will not be running the machine several hours a day - will not be heavy usage. Dare I ask opinion on server vs. clutch motor? Or is that too controversial? The seller offered to let me try it first and swap out if I want the servo motor - what should I look for when I test it? Thanks all.- 7 replies

-

- sewingmachine

- consew

-

(and 1 more)

Tagged with:

-

I want a walking foot leather sewing machine. I found a couple of used machines available in my area - a Consew 206RB-4 and a Chandler (Adler) 67. I would use to sew veg tan leather - bags and other similar items. In general which would be a better machine? The used Consew is more expensive, but I am more interested in which one will be a better machine over time. If they are roughly equivalent I may go for the cheaper Chandler. What thickness of leather layers could I expect each of these machines to sew through? Will one sew through a thicker layer of leather than the other? Thanks for any comparative advice. The Chandler is fitted with a servo motor, not sure about the Consew.

- 7 replies

-

- sewingmachine

- consew

-

(and 1 more)

Tagged with: