-

Posts

1,808 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by hidepounder

-

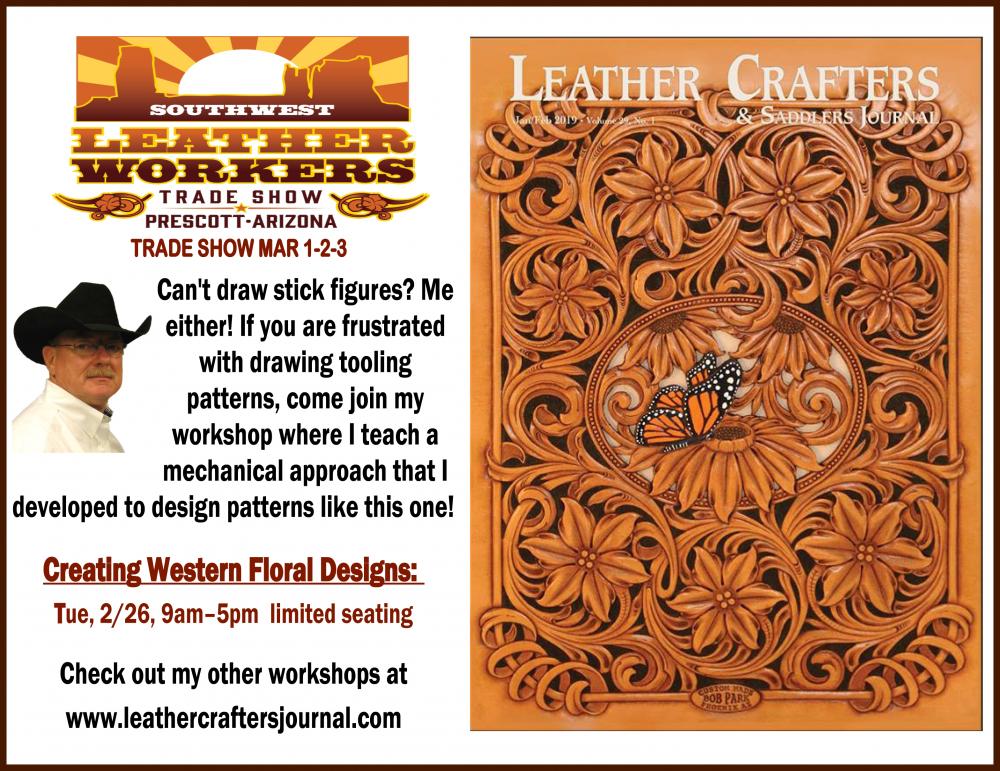

ADDITIONAL WORKSHOPS: Bindings & Turned Edges Demonstration: Tue 2/26, 7pm-10pm Western Floral Tooling: Wed 2/27, 9am-5pm Filligree Backgrounds & Inlays Demonstration: Wed 2/27, 7pm-10pm Antiquing, Dyeing & Finishing Demonstration: Thu 2/28, 9am-12pm Burnishing Edges Demonstration: Thu 2/28, 2pm-5pm Registration: www.leathercraftersjournal.com Bobby's contact info: hidepounder@gmail.com 602-999-3099

-

-

Art of the Cowboy Maker - Classes

hidepounder posted a topic in Special Events, Contests and Classes

-

-

It depends entirely on how wet it was when you put it in the plastic bag and the humidity in your environment. If it had turned partially back to it's natural color, then it should be toolable soon. But if it was very wet when it went into the bag, then you will have to wait and it won't be properly cased. To case properly, the leather has to breath a little but must remain in a super humid environment while it returns to color. Old ice chests make good casing boxes, especially if a couple of adjustable air vents are installed. Hope this helps! Bobby

-

Bob Park Workshops

hidepounder replied to hidepounder's topic in Special Events, Contests and Classes

Looking forward to a visit, Bruce! -

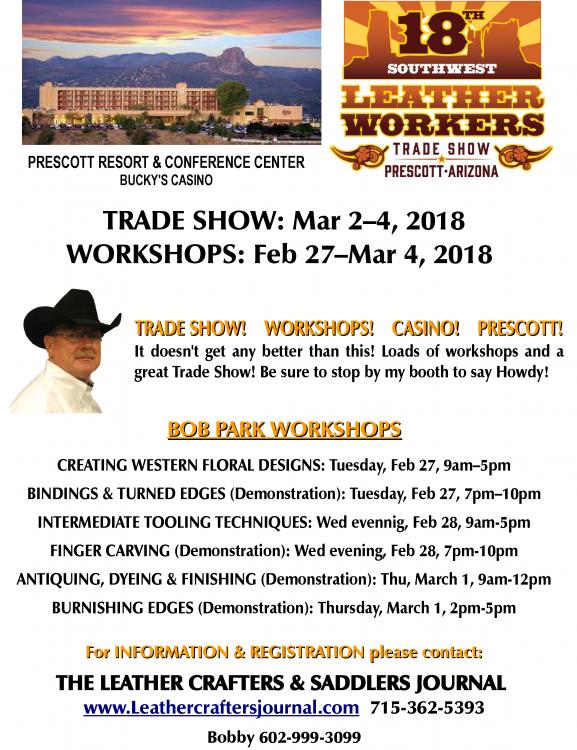

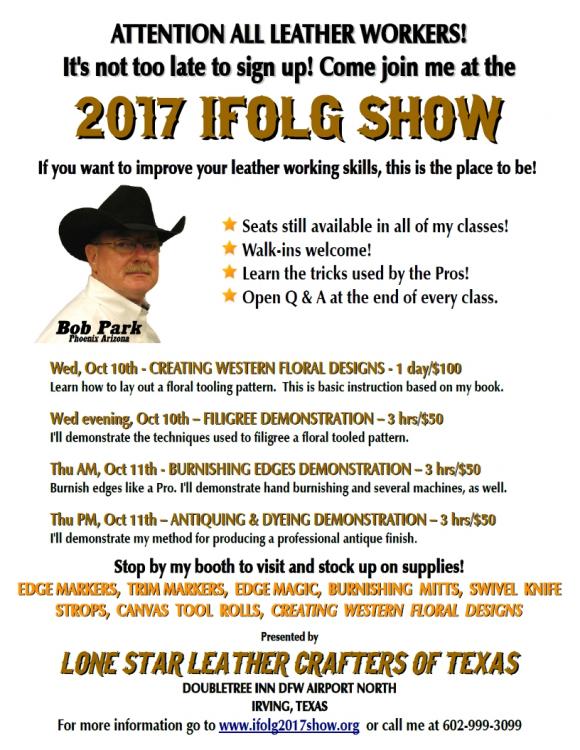

For anyone who might be interested, it's not too late sign up. I still have a few seats left in some of the workshops and I will be accepting walk-ins, first come first serve for any remaining seats. Contact the Leather Crafters & Saddlers Journal for more info (715) 362-5393. This is GREAT SHOW in a beautiful facility. Feb 21-26. Don't miss your chance to see a great variety of vendors under one roof. And be sure to stop by my booth, located in the foyer, and say hello! See you there!!! y

-

Saddle Stitching, Front/back Look Different?

hidepounder replied to bigtree's topic in Sewing Leather

Great post Michelle and very informative! And beautiful sewing, BTW!!! In case you haven't run across them, the best stitch groovers that I have ever found are manufactured by Bob Douglas in Sheridan, WY. He makes the Versa Groover which is a guided groover and he makes two sizes of hand groovers. All come incredibly sharp and ready to use. The tip provided on the Versa Groover is the best I've ever found. The hand groovers are also great to use as gouges in light leather to create fold lines. These are in a class of their own with regard to groovers. I also like to use the Horse Shoe brand groover which is a caliper style groover like the C.S. Osborn groover and I use a Versa Groover tip in it as well. For me the down side of using a groover is that your are cutting the strongest surface on the leather which in principle is creating something of a weak point. And maybe even more important is that you are creating a track for dirt and sweat to catch in which is pretty tough on thread. So IF thread can be recessed into the leather by embossing a groove which does not cut the leather (you use a creaser for this), but helps to drop the stitch below the surface plain of the leather, that is probably a better alternative. This can also accomplished with a pair of dividers with tips that have not been sharpened. On western gear, the strength issue is a non-starter because we're talking about 15 oz leather. I do groove belts, however, because I have seen so many with the stitching worn completely off! In this instance I'm using 6-7 oz or 7-8 oz veg tanned leather with a lining which brings the belt up to around 12 oz total weight. Has anyone ever wondered why stitching groovers were invented in the first place? There is a reason why creasers, skirt channelers, straight channelers, edge channelers and gum tools were developed in the first place. The were developed by companies like Dixon, HF Osborn, CS Osborne, Blanchard, Gomph and probably other companies that I'm not even aware of for use in the HARNESS industry! Gomph and Osborne were making them in the mid 1800's. During WW1, British and American saddlers boxes included both groovers and channelers. I'm sure they were included because it was unnecessary to use them, right? And for the record, Martyn, Americans used horses to perform all those same tasks both here at home and in the Military and in Europe! Before I go any farther I want to make something very clear to everyone following this thread. I am NOT an expert of any kind on hand sewing. I hate to sew and there is no one in the leather industry who is worse at sewing than I am! I use a sewing machines and only hand sew when there is simply no other alternative. And my hand sewing always looks bad! I only wish I could sew as well as Martyn or Michelle! So I just want that on the record before I go any farther. And for those of you who are tired of reading the bickering between Martyn and me, I promise this will be my last post on the subject! Martyn can have the last word. Martyn, I resent you putting words in my mouth! I NEVER said nor inferred that English saddlery is inferior to western saddlery! It is not inferior, and I sure as hell don't need you to clarify that for me! I have the greatest respect for the quality of craftsmanship which goes into English saddlery. English saddles are for more refined than western saddles. However, English saddlery is NOT as robust as western saddlery and it's ignorant to suggest that it is! That comment is in no way a criticism of English Saddlery, Martyn and I suggest that YOU are the one being defensive!!! An English saddle is not designed to the same job that a western saddle is. A western saddle cannot preform the same tasks as an English saddle. I believe most people would opt to use the right tool for the job. Why would anyone use their family car when the job requires a tractor? It's not a difficult concept! ? I simply cannot understand why anyone would suggest that an English saddle could withstand the abuse expected from a western saddle! It is simply preposterous to compare the performance of the two. They just couldn't be farther apart when it comes to design or use! There is simply no reason for an English saddle to be constructed that way. Saddles are constructed differently for different types of work. It sure as hell doesn't mean that one is superior to the other! Who in their right mind would tackle a cross country jumping course in a western saddle? Where European style saddles are made of lightweight leather and are primarily used for pleasure riding and sport such as jumping, hunting and racing. Not working and roping cattle! Western gear was developed for the working cowboys who spend entire days in the saddle while working cattle in a harsh environment. The reason cowboys ride the much heavier western saddle is because the job cannot be accomplished with English style equipment!. Cattle ranches can span hundreds of square miles. Some are larger than our northeastern states. The cattle on these ranches are not domesticated animals which can be managed on foot with staffs as they primarily are in Europe. We are talking about ranches which are tens of thousands to hundreds of thousands of acres in size and have thousands of head of cattle. The point being that the difference in cattle management on a European farm is dramatically different than that of an American cattle ranch. You will NEVER see and English rider and horse cut or turn back cattle! You will NEVER see an English rider turn a steer running full out. NO rider could remain in the saddle performing those moves in an English saddle. The western saddle was designed to withstand the rigors of riding day in and day out and withstand roping functions in order to perform tasks like capturing wild cattle, branding and doctoring out on the range. If you think an English saddle could stay together when connected to an 800-1000 lb steer strying it's best to escape, you delusional! It's the reason western saddles are constructed of 15 oz veg tanned skirting leather on heavy wooden bullhide covered trees instead of 6-7 oz. leather and very light trees found on European style saddles. Cowboys often travel many miles a day horseback while working cattle. In many parts of the western U.S. the geography is very rugged and one man may need to ride more than one horse in a day, in order to complete their job. The manner in which western saddles are constructed is also worlds apart from the European saddle! Western saddles have layers ofheavy leather that overlap and move against each other. European saddles are not made that way! There are more moving parts in a single western saddle fender and stirrup leather than in an entire English saddle! I'm not an expert in any of these fields, but having been involved with cattle ranching, I feel very comfortable in saying that there are no similarities for comparison between European and Western equipment! So my hackles go up, Martyn, when someone with no knowledge of the demands placed on western style gear, suggests that English style equipment is proof that unprotected thread will outlast the leather it's in or the individual who's using that equipment. That's just silly! Remember, Martyn, that this little squabble came about when you so blatantly professed that there is just no need to recess stitching on ANY gear because the thread will simply outlast it! You put words in my mouth again when you professed that I said all stitching should be placed in a stitching groove! That's not true! You made assumptions beyond my intent! Oh and by the way, Martyn, it is generally accepted that horses were first domesticated in Eurasia, not England! And what the hell does that have to do with this discussion anyway? Is your point that harness work, which isn't used for western work, is somehow tougher? I suggest you visit a working cattle ranch where hundreds of head of UNDOMESTICATED cattle are being roped, branded, tagged, vaccinated, de-horned and castrated, while tied to the saddle horn and explain to me how well an English saddle would done the job! I consider hand sewing to be a real art all in itself and I have tremendous admiration for all of you have been determined and dedicated enough to become good at it because I am not! I love my Adler and my Cobra and would be in serious trouble without them, LOL! Anyway, as promised I'm done bickering and arguing about this, LOL! I hope everyone reading this thread has been entertained, but I'm really weary of this discussion. I've tried to make a simple point and if I've failed I apologize for wasting time. Lets argue about something else, like maybe, which tool is better for beveling? A modeling tool or a beveler!!! Bobby -

Saddle Stitching, Front/back Look Different?

hidepounder replied to bigtree's topic in Sewing Leather

Didn't say there was one. It either has an embossed groove (developed with a creaser) or is just pulled down tight enough so that the stitches are below the plain of the surface. To my way of thinking, that's superior workmanship. -

-

-

-

Saddle Stitching, Front/back Look Different?

hidepounder replied to bigtree's topic in Sewing Leather

Martyn, I'm sorry, but I just can't accept your full statement! In my opinion you are still painting with too broad a brush. And by the way, who said Stohlman's methods or the western style was the only way? I certainly did not! Just for the record, the adaption of a stitching groove had absolutely nothing to do with Stohlman. The application was used throughout the harness industry and the western saddle industry LONG before Stohlman's time! That's not a particularly important point, but there it is none the less. I don't understand why you are insisting to presume that the conditions and standards which you prefer are applicable everywhere. In fact, I would submit to you that the finest English saddler in the E.U. sews everything by hand and uses a relatively small thread with a high stitch count which is all recessed! Don't take my word for it, though! I invite you to visit the site of Jean-Luc Parisot in France. Here is an example of his work and a link to his site: http://parisotsellier.com. I have no bones to pick with anyone who wants to stitch everything by hand or use thread which is over-sized for the job. There is a market for that particular look, especially among the hand stitching purists. If the craftsman does a good job of it, they have my admiration, such as I expressed to you in my first post. However, I will continue to utilize the finer recessed stitches on my products. I believe it makes for superior construction with a more refined appearance. And please, don't tell me that large unprotected stitches will outlast both the leather and the user! I hear you selling, but, I'm just not buying it, LOL! Have a great weekend! Bobby -

-

-

-

Saddle Stitching, Front/back Look Different?

hidepounder replied to bigtree's topic in Sewing Leather

OK, I'll bite! Where did you read that I said stitching HAD to be recessed? I simply stated a reason for recessing thread. Also, I don't recall making ANY statement regarding the durability of a linen saddle stitch! The backpack is really cool and obviously very well taken care of. The straps are only stitched where the leather is turned on the hardware, which is not an area that receives any abrasion. And what about the turned edge at the top of your photo where the stitching has definitely been recessed into the leather by pulling it down tight?.With regard to the backpack's possible 70 year longevity, I hope you're not suggesting that it has been in constant rigorous use for the last 70 years! I do take exception with your comment about English saddlery! The stitching on any quality English or Hunt Seat saddles that I've seen, look nothing like the stitching in your photos. I am in no way criticizing your sewing! It is very nice and far superior to mine, I assure you. Nor am I any kind of authority on English saddles. But I've been around a lot of them and the three that are in my barn all have refined stitching at 10 or more stitches per inch with a much lighter thread, that is most certainly pulled down into the leather! Your comment "....but for general surface stitching, even on items that are destined for extremely hard use, it's absolutely not necessary." may be appropriate in Great Britain, but I think you're painting with too broad a brush. Western gear construction and materials are much more robust than English gear because western gear is required to take a lot more abuse. It is not uncommon for saddle seats and fenders made of 15 oz leather, to be worn paper thin after just a few years of constant use. Anyway it has become somewhat traditional to place stitches in a groove to help protect them. It has become part of the western "look" which people are accustomed to seeing. So grooving is often performed as much for it's look as for necessity. Generally, the thickness of the leather used on western gear will usually tolerate grooving where it would be detrimental on the lighter, more refined leather used on English gear. I personally like to see a stitching groove (cut or embossed) as long as it doesn't create weakness. And with the amazing contact adhesives we have these days, sewing is often only a back-up for the glue anyway. So I guess we'll just have to disagree about the durability and appearance of exposed or unprotected stitches. I think it would be fair to say it all hinges on the application. Just my humble unqualified opinion..... Bobby -

-

-

-

-

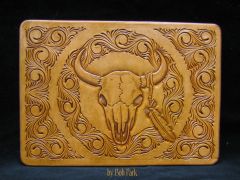

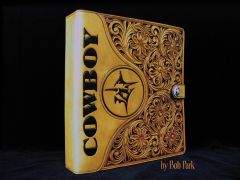

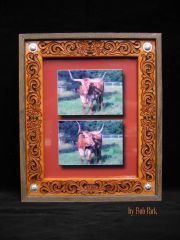

From the album: Bob Park

-

-

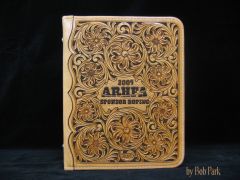

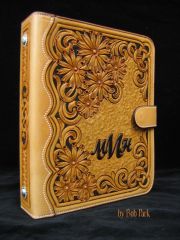

From the album: Bob Park