buko

Members-

Posts

23 -

Joined

-

Last visited

Profile Information

-

Location

Vancouver, WA

LW Info

-

Leatherwork Specialty

Bags, wallets, notebooks, sheaths

-

Interested in learning about

machine sewing

-

How did you find leatherworker.net?

google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

buko's Achievements

Member (2/4)

-

Jimmy, I made you a version of the logo you can send out for a stamp to be made. Its not perfect - just did it real quick but you can have them adjust it for you. PM me your email and I'll send you all the files if you can't download these here. md club logo.pdf md club logo.svg

-

It appears that adjustment worked. At first when I tried it the thread was still fraying so I took the plate off and noticed that the hook was splitting the thread. I replaced the needle and it started sewing fine. I guess I must have bent it at some point. The thread I have seems to fray very easily though. Its bonded nylon from Superior Threads but I'm not sure if I'm really a fan of it.

-

Ok, this sounds like what is happening. I see the thread go really slack as the needle makes contact. When you say "lengthen the stroke" do you mean adjust the tension or do you mean rotate the check spring counter clockwise? Or both?

-

Let me first start by saying that I know very little about sewing machines. This is the first one I've ever used. I've been researching for months and finally bought a used Consew 206rb-2 from a local sewing machine mechanic that restored it. To use it for leather, I replaced the motor with servo, put a 50mm pulley on the motor and replaced the wheel on the machine with a 145mm pulley which has slowed the machine enough that I can control it. Now the problem: any time I try to use a 135x16 size 22 needle the top thread comes unwound and breaks. I've tried both #138 thread and #92 thread with the same results. When I use a 135x17 regular needle it sews fine. I've checked the hook timing (after watching videos) and it appears to be ok. I've adjusted the tension and it doesn't seem to affect anything. I've attached a photo to show what I'm getting. The stitches on the brown leather are with the normal needle and the ones on the black leather are with the leather needle. The blue thread is #92 and the black is #138. What am I doing wrong?

-

Before the finish but I caution you that if you aren't going to use a natural finish like beeswax or carnuba wax you may not get good results. You are oiling the leather after all and most finishes won't adhere to oily leather. I would test the resolene on some scrap after the oil has "dried" for a couple of days. Kiwi neutral polish may be an option for you rather than resolene since it is designed to go over the top of waxy finishes. I don't use resolene so I can't really help you with that one honestly.

-

You can use neatsfoot oil anytime after tooling but if you are going to dye the piece use the oil after dying. The oil usually causes more of the dye to come off so be aware of that. I use a 50% beeswax 25% neatsfoot oil 25% beef tallow homemade balm to finish my pieces. I warm the leather before applying to help it soak in. It softens the leather and gives some water resistance to the piece. Best thing to do is test on some scraps and see what you like the best.

-

Onto the third bag....

buko replied to motocouture's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Gafer, what kind of bag do you want to make? I highly recommend you buy the build along patterns from either Ian Atkinson or Nigel Armitage both of which have good instructions and are only £10. Also, the book "The Leatherworking Handbook" has great ideas and techniques and is worth its weight in gold. -

Extra slick flexible finish

buko replied to bai's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

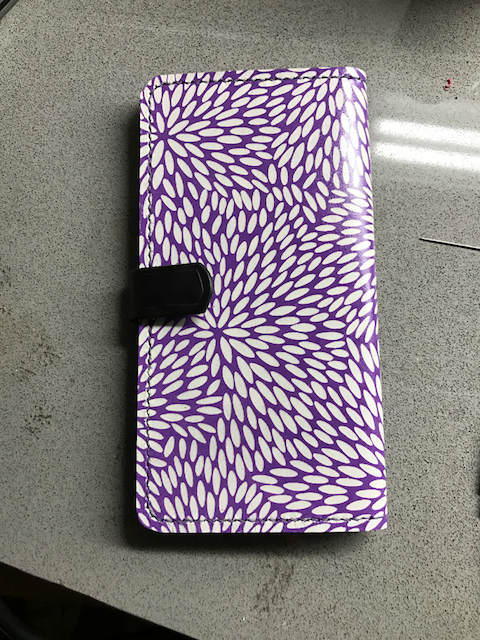

If by "slick" you mean glossy, you could try Kiwi Neutral polish. If you mean slick as in plastic coated you can try Mod Podge. I use it on some washi covered wallets and bags that I make and it will fold without cracking. Not sure what you mean by thousands of times though. Here is a picture of a leather wallet, coated with paper and Mod Podge -

Ken, if you want to take paypal all you have to do is send the buyer the email address you use to login to your paypal account. They use that email address as the recipient. You can also get their email address and send them a bill from paypal which is a little easier. Hope that helps!

-

First off, I know very little about sewing machines so take what I say with a grain of salt. But my first thought when I saw Uwe's post was maybe you could buy a spare spring and shorten it to reduce the pressure.

-

Thanks Wiz. I have plenty of needles in all sizes but I was specifically looking for the "LR" or "LL" needles that add a slant to the stitch as shown in this picture from the Groz Beckert brocure:

-

Perfect! I'll call and order tomorrow.

-

Thank you. May I ask where you special ordered from?

-

I just bought a Consew 206rb and I'm in the process of getting it ready for leatherwork. Studying all the great posts on this site it looks like I will mostly use size 138 thread for much of what I want to do. Looking at the Groz Beckert guide, it looks like I want the LR points to approximate the look of a saddle stitch but I can't seem to find the size 22 (for the 138 thread) in stock anywhere online. Searching this forum it appears to be a common problem. That said, can anyone recommend a different manufacturer that makes a similar slanted point in that size? Thanks!

-

what leather would you use for this project?

buko replied to rmr's topic in Leatherwork Conversation

Bridle or Latigo would work well for that. Ask your supplier to split it to the thickness you want.

.png.d07f5d7656144c4ec27f3ef77682e1ab.png)