-

Content Count

481 -

Joined

-

Last visited

Posts posted by cdthayer

-

-

Is your check spring releasing its tension when the needle tip gets close to the bed surface?

CD in Oklahoma

-

What a difference a correct hook can make. I put hook #37854 in, and the missing stitch problem is gone. I test-sewed a vinyl and woven “sandwich” with Tex90 thread and a size 18 needle, and it sewed just fine. Then, I test-sewed a quilting cotton and batting “sandwich” with Tex30 thread and a size 14 needle, and it sewed just fine with the thin thread.

I intend to use this machine as a straight-line quilting machine for my wife. I’m not sure if she’ll take to the treadle or to the machine, but she’s going to give it a try. If it turns out that she doesn’t “bond with it”, I can always set it back up for heavy work and put it back in my sewing area. I think it would be great for woven saddle blankets, dog beds, and that sort of thing.

CD in Oklahoma

-

“Singer 78-1 vs 111w155 - how these machines are different?”

Hi Yetibelle. They compare about like apples and oranges. I have both types, and while they’re not those exact machines (mine are Singer 111W153 & 78-3), I don’t see either one replacing the other. While they can both do some tasks about the same, neither one can do all of the tasks that the other does. If you have the chance to snag a 78-1, I don’t think that you’ll be stuck with two machines that do the same thing, if that is your concern.

CD in Oklahoma

-

I would check for two things: needle height and check spring operation.

Needle deflection can cause the needle tip to hit things it’s not supposed to hit, and could cause the marks on your bobbins.

If the thread tension check spring is not releasing to allow the thread to form a nice loop for the hook, but instead holding the loop snug to the back side of the needle, the hook tip can pierce the thread instead of going into the loop.

CD in Oklahoma

-

8 hours ago, Darren Brosowski said:doing about 180

Never have been anywhere close to that fast on a road, but I have done a few "one-eighties" on roads covered with black ice over the years....

CD in Oklahoma

-

3 hours ago, JLSleather said:Somebody jus offered me $38 for a holster

...and they will expect a "no questions asked return policy" for that kind of money too....

CD in Oklahoma

-

....not my favorite job, but the Singer 16-41 treadle makes replacing a front zipper in insulated overalls go as well as can be expected. (Tex90 thread top & bottom, size 18 regular point needle, #10 brass zipper.)

With manufacturer’s putting small zippers (size 7 maybe?) in new work clothes these days, I will probably get lots of practice in replacing zippers.....

CD in Oklahoma

-

Gotta love the old iron.

CD in Oklahoma

-

-

I’ve been setting up my 1950 Singer 78-3 needle-feed machine that I finally got hauled home from OKC. It was in an old H-leg power stand when I bought it. I gave the stand & clutch motor to my son-in-law and mounted the small 18”x42” slab top onto my household MUTT (Multi-Use Traveling Treadle) stand. I have multiple tops for my MUTT so that I can use it with a variety of machines. This is the first industrial machine top that I’ve fitted to it. The top was only drilled for a motor, so I had to drill a second hole for the treadle belt. I guess that by 1950, tops didn’t get drilled for both treadle and motor power. I’m also using a smaller 3/16” household leather treadle belt on it for now until I see how much slippage that I get. I’m not going to be sewing dense leather with it, so the small belt may work fine. I use a 2-piece belt on my MUTT, a long piece and a short piece, so that when I change tops and machines, I can just change the short piece.

I need to get a spool pin on it, a new hook, a second face plate screw, and do some more cleaning on it. I still need to mount the knee-lifter back onto the underside of the top too. It’s a Simanco #228360 lift that mounts on one side of the top, and is not the lift shown in the 78-3 parts list, so the top must not be original to the machine. The hook that was in it is for a 31-15, and without the big needle in it that it came with, a size 18 needle won’t pick up the Tex 90 thread that I’ve test-sewn with. Hopefully, the correct hook will solve that problem. I’m not sure what I’ll use the 3SPI for, but I like the long stitches. Even with a treadle, it doesn’t take long to get somewhere with that long of a stitch.

CD in Oklahoma

-

6 hours ago, TinkerTailor said:One thing i know is the white machines turn the opposite way singers do.

FYI - Be careful with that statement, my friend. White Rotary machines turn opposite Singers, but White VSIII (Vibrating Shuttle - third version) machines turn the same way as a Singer. Not trolling you, just letting you know....

CD in Oklahoma

-

If you haven’t already, remove the needle plate and check for a build-up of lint and gunk restricting the travel of the feed dog. Watch the feed dog while you hand wheel the machine, to see what kind of movement you’re getting. Make sure that the teeth of the feed dog comes up above the needle plate (about the thickness of a US dime) so that the teeth are gripping the work good.

I have a Singer 95-40, and the maximum stitch length on mine is 8 SPI, so mine won’t make very long stitches.

CD in Oklahoma

-

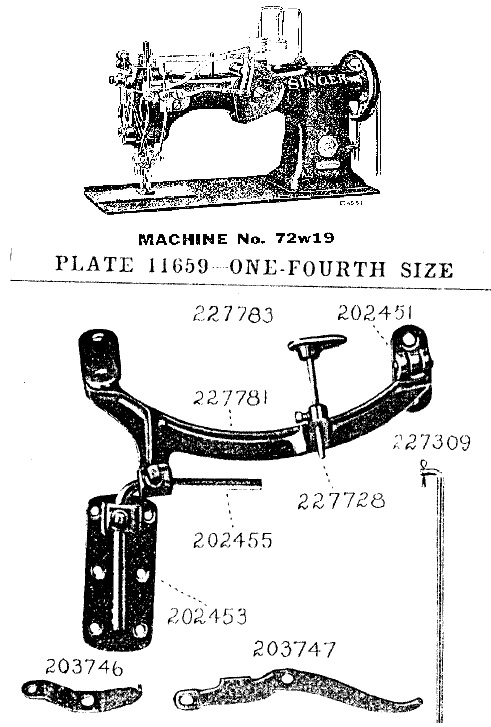

13 hours ago, Yetibelle said:I suspect if is from the 72W19 machine that is also early 1900's.

I’d say that’s fairly likely. I wonder if the lift with part number 227781 was a Wheeler and Wilson design that Singer got when it took over W&W in 1905?

CD in Oklahoma

-

You’re right machinehead! Thanks! You got me to looking through old parts books, and I finally found a reference to it in the parts manual for a Singer 72W19 hem-stitching machine. So I guess maybe it is a Singer lift after all. Maybe the part was made by Singer before it got into such a war with people trying to copy the Singer parts and started putting Simanco on nearly everything?

I don’t find a copyright year on the parts manual that I’m looking at, so I still don’t know when this style of lift may have been common.

CD in Oklahoma

-

On 12/6/2016 at 1:34 AM, Darren Brosowski said:I do not suggest old iron to new sewers in most cases as it takes some getting used to.

That is a beautiful machine. I have to say that I have never seen that type of knee lift and I am not even sure that it is Singer.

Does it say "Simanco"?

I understand why you don’t suggest old iron to new sewers much. I don’t recall ever getting one that I could set down to and sew as-is when I first got my hands on it. That can be a problem for new sewers, but for old iron collectors like me, it’s just part of the fun. Getting them to actually sew well again is even more fun. Being able to use them in my repair business is an added bonus.

Thanks for the compliment on the machine. I bought it as-is and untested at the Wichita Falls Texas Boot Show this past October. It came out of Colorado, but other than that, I don’t know any history about the machine. The more that I use it though, the more likely it is that it will replace my Singer 31-15 roller foot as my go-to light stitcher. I’m sure liking it so far.

The old knee-lift doesn’t have any text cast or stamped on it that I can find. It only has the number 227781 cast in large numbers as shown in one of the photos. Chances are, it’s probably not a Singer-made lift. Singer tended to put Simanco or some other identifying text on most of their stuff, especially parts as large as a lift. There is no number at all on the back of the knee pad, which is not like Singer at all. The lift came to me from that online auction site several years ago, along with another “unknown brand” unusual lift and a genuine typical Singer lift that I used on another treadle stand.

CD in Oklahoma

-

Yea, I think he's right, a hollow rivet. What's it look like on the other side? Do you know?

CD in Oklahoma

-

My 1917 Singer 16-41 is approaching its 100th birthday at the end of August of next year (probably made sometime during September or October), and I guess it will then officially become an “antique”. I’m running Tex90 thread in it with a size 18 needle, and it clicks right along. The outer foot clicks every time that it takes a stitch, and I like that. The sound reminds me of my Singer 29s.

I had a small alterations job come in last week that it handled just fine. I had to move the leg zippers over to snug-up the fit around the thigh in a pair of old shotgun chaps. The small foot on the 16-41 let me stitch closer to the zipper slide than any of my other walking foot machines would have allowed. Everything went fine except that I was reminded right away that I hadn’t gotten around to mounting a presser foot knee-lift lever on the treadle that it’s in, so I got busy this morning and mounted one on it. I selected an old knee-lift that may be of about the same vintage as the machine, and one that I don’t see very often. Its part number is 227781 if anyone has any information on the time period that the style may have been used. I figured that this application was a good place to use the less-adjustable light-duty rigid style of lifter.

CD in Oklahoma

-

If you’re talking about the cone bearings in each side of the foot plate, they have a straight screwdriver slot in the outer end that you screw them in and out with to adjust the bearing. The nut on it is a jam nut that has a normal right-hand thread.

Lift the head out of the stand, tip the stand forward or backward, loosen the jam nut with a wrench, and unscrew the stud.

CD in Oklahoma

-

On 11/10/2016 at 5:30 PM, TinkerTailor said:Also, I think we need to keep the last 100 years of US foreign policy and the problems and solutions created out of this conversation. The US is not going to get great by messing with other countries. They need to clean up their own house before looking at the neighbours.This is a whole additional topic.

I’m thinking that you have said that your country, Canada, has a VAT tax. It also seems to come up from time to time in other threads talking about folks in other countries than the United States when talking about buying sewing machine parts and other things from the US.

How is a VAT tax different from a tariff?

CD on Oklahoma

-

1 hour ago, JLSleather said:ther's some "wiggle room" in the pricing around here

A motorcycle-riding acquaintance of mine had brought me some sewing business from time to time, sewing embroidered patches on his vest, repairing a side seam in his chaps, and one thing and another. One day he brought in a pair of slip-on work boots that both had the back side ripped open right above the heel (a crease had finally failed in old fatigued and rotting leather when he used his bootjack to pull them off). He just wanted me to overlap the rip and sew it back together to get just a little bit more use out of his boots. I could do that on my boot patcher. He was razing me about not charging him more than the boots were worth. I didn’t think that the boots were worth very much, but understood him wanting to get by for a payday or two until he could buy a new pair. I think my shop labor rate at the time was $18/hour for sewing repairs. So, in an effort to avoid insulting him, I told him to just pay me what he thought my sewing was worth to him. He paid me a dollar a boot and went on his way. I didn’t say a word.

It was a fairly long while before he brought anything in for me to work on after that, and then one day he dropped off one of his motorcycle semi-rigid saddle bags at the shop to have sewn back together where some stitching had failed. To make a long story short, it took me the longest time to decide the best way to repair that saddle bag, and I didn’t ask him how much he thought it was worth to him. I already knew the answer to that, so I charged him what it was worth to me for my careful planning and excellent sewing services. He paid it, and didn’t say a word.

CD in Oklahoma

-

Weak presser foot down-pressure can let your work lift up along with the needle, keeping the loop from forming large enough, but I don't see how dropping a needle would change your presser foot pressure....

CD in Oklahoma

ETA: I just thought of something else. I know that you said that it is threaded right, but check close to make sure that your thread isn't looped behind something that is hampering smooth feed of the upper thread. Dropping a needle could cause a quick jerk on your upper thread during the commotion, causing slack in the thread that can get out of place and foul somewhere along the line...

-

We haven’t heard from the American sewing machine sellers that are selling machines made somewhere other than in the USA. Is there much concern that possible Trump changes in Trade Agreements and his tariff comments might make things rough on sewing machine sales?

CD in Oklahoma

-

Before we get too far away from the original thread label of "Make America Great Again" and the leather trade, I have a question for the production people (I’m not in production, just repair and mending).

I read an article the other day that suggested that the Baby Boomer retirees are causing the luxury item industry to branch out into travel and amenities. It seems that the current retirees aren’t spending as much of their money to buy items, but more for services these days. If so, I’ve wondered if the custom leathercraft community has seen a real decline in “retirement spending” for their high quality leather items?

On a side note, I had a police officer come into the shop the other day to get some minor repairs done to his duty rig, and I remember commenting to him at the time that there wasn’t one bit of leather on the entire rig. Everything that used to be leather on a rig was a man-made material of one kind or another on his. He said it’s what officers are mostly using now. The increased non-use of leather for traditional applications has got to be hurting the leather industry.CD in Oklahoma

-

Check your upper threading again. Better yet, take the upper thread completely out and re-thread it. Something as simple as missing the check spring when threading can cause missed stitches.

CD in Oklahoma

Cast Iron Again - Pearson & Bennion / BUSMC A1

in Leather Sewing Machines

Posted · Report reply

I use a handcrank bobbin winder with a leather belt on it to wind the bobbins for my Singer 31-15, Singer 16-41, and Adler 205-64 machines. It has a tapered shaft to mount the bobbin on, so it would work for some of my other machines too, but they’ve all got their own surface mount winders. The 205-64 bobbin goes onto a piece of rubber tubing forced onto the smaller of the two tapered shafts. I set the cone of thread on the floor or in a portable cone stand, crank with my right hand, and feed thread with my left hand.

CD in Oklahoma