drumminor2nd

Members-

Posts

13 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

WNY, USA

LW Info

-

Leatherwork Specialty

Holsters and other small items

-

Interested in learning about

Belts and sewing

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

drumminor2nd's Achievements

Member (2/4)

-

What's the patent number?

-

I promise, nowhere near done yet -- just did the stitching and was excited that it worked so well. Willow appears to be half muted calico and half dog (chases her tail, plays fetch, sits and stays, begs for table scraps, etc.).

-

Hey, all. I scrimped and saved to get a leather sewing machine that could handle thick holsters and the like, but also not cost $3,000 for the thickness I plan to sew and the accessories I desired. I went with the Weaver Cub for a couple of reasons -- I like the hand crank over the lever (personal preference, I guess), after adding a material guide and shipping it was only $150-ish more than a Cowboy Outlaw -- and made in the USA. Unfortunately, it's been chronically out of stock for at least a month since I set my sights on it. Fortunately, it popped up in stock for about 30 seconds last week, so I ordered it. It came yesterday in a big box ready to go. I clamped the board it came on to my work table, hit the oil points, and tried out a piece of scrap or two. I figured out a stitch groover gives the best result, and I learned how to use the stitch size adjustment. After about 10 minutes, I felt ready enough to attack my first project -- a simple holster for an 1860 Army I own that I was putting off sewing up by hand. I think I'm getting the hang of this. Also, with very little fiddling, I worked just as I hoped (for $1,900 after tax, it better work out of the box...). I need a hammer to flatten out the stitching a bit afterward, but I'll get one this weekend. A cheap LED light will also come in handy. I think it's pretty easy to just keep cranking in a straight line on it. I think I need a new belt next... Attached are the first project, and the machine (with cat for scale). Quick question: I know the needles are the same as the Tippmann and Cowboy machines, but what about the bobbins? Also, where's everyone's favorite place to pick up thread? It came with half a pound of white 207, and I want some brown 277 next.

-

Tippmann Boss or Cowboy Outlaw packages?

drumminor2nd replied to drumminor2nd's topic in Leather Sewing Machines

Hmm... that would make it much easier to make belts... hmm... -

Tippmann Boss or Cowboy Outlaw packages?

drumminor2nd replied to drumminor2nd's topic in Leather Sewing Machines

I like where your head is at. I'd be interested if Weaver had them in stock. The price is $300-$500 more than the others, too, but I wouldn't be opposed. -

Hey, all. I'm looking for a machine for sewing holsters and knife sheaths, maybe the occasional belt. The wife and I agree that I can't spend $3,000 on a sewing machine for a hobby -- so no motorized machines unless I find one for a steal -- but I can handle $1,500. So that has me looking squarely at the Tippmann Boss and the Cowboy Outlaw. I know hand cranking a belt is going to suck, but any more than doing it by hand? (did that once, not planning to repeat it). I figure if I ever get going making things for money I can sell/trade in whatever I buy toward an electric later on. It looks like they both sew about the same thicknesses, use similar thread sizes, etc. The Outlaw has more throat distance that's more "square" and useable, while the Boss weighs half as much (good because I have a bad back). It's going to mostly live in one place for now, but it may end up being mobile later on. Tippmann offers a setup on their website with a material guide, stirrup attachment, left and right pressor feet, center and fleece feet, six extra bobbins, as well as all the normal stuff for $1,209. https://tippmannindustrial.com/tippmann-boss-leather-sewing-machine-deluxe-package/. That's looking like a winner for me unless there's a similar setup for the Outlaw. Anybody know of one? I see this one has some of the things I'd actually use in it, wondering if this is a good seller or if there are alternatives: https://brodbeckironworks.com/products/cowboy-outlaw-hand-operated-leather-sewing-machine

-

I'm not going to lie -- I swiped a bunch of the patterns when you had them up. Including one for a Smith & Wesson J-frame. Did I own a J-frame? No, I'm just a packrat. I even made one for an LCP, even though I haven't ever held one, much less owned one. Fast forward to last week, and I bought a J-frame (Model 37 Chief's Special Airweight). I designed a pancake holster and made that -- I think it sat too low, though, and I was so off on my measurements that after wet molding it I threw in another stitch line along the trigger side by a 3/8 to half an inch to compensate. The next day, I found your pattern again on my computer and decided to knock one out with some stamping, dark dye and contrasting stitching. Still need to do some finishing work on it, but the pattern was sound. I just wanted to say "Thank you!" for your hard work on these patterns.

-

Need part for Chinese patcher

drumminor2nd replied to drumminor2nd's topic in Leather Sewing Machines

Thanks, all. Seller said they would ship it (I may or may not have asked for some more bobbins and needles to make up for the delay and shipping method, no point getting greedy). But I think I'll give making one a go anyway. Got a piece of scrap handy and everything... -

Need part for Chinese patcher

drumminor2nd replied to drumminor2nd's topic in Leather Sewing Machines

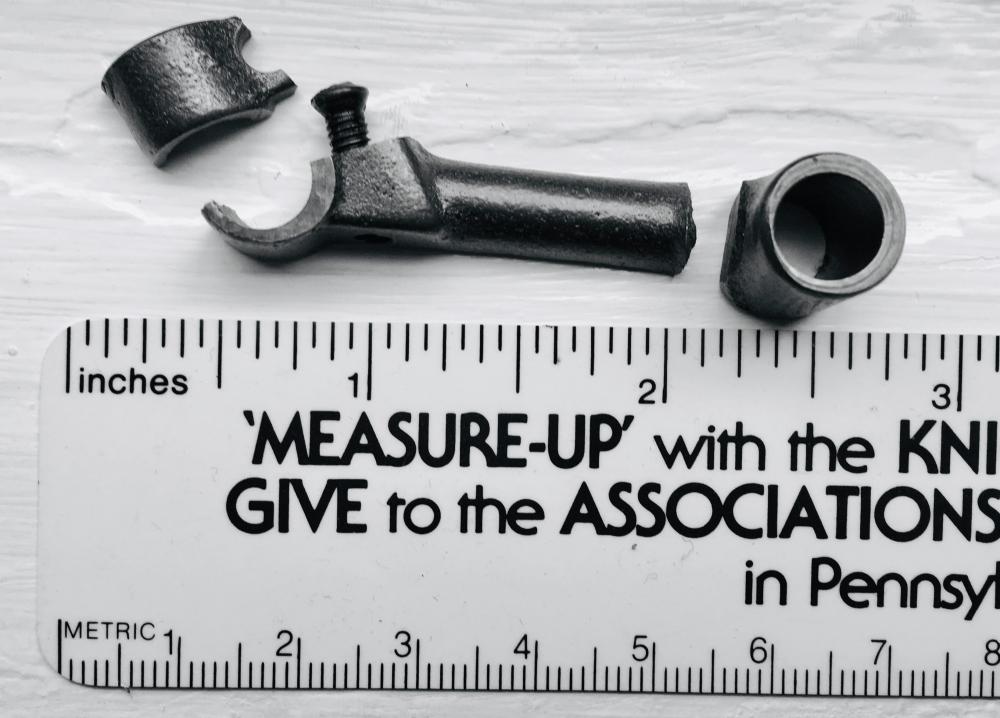

Well, the seller said this morning to send pics of the part and where it goes (attached), so I'm expecting a new part at this point -- if I don't get it, I'll have to escalate things with eBay. I really don't want to ship it back across the country just to take a lottery spin on another one -- this one works relatively smoothly minus the one broken part (and I don't want them to send this one back out with the broken part . Except for fear of the clamping force, I bet I could get that to JB weld back together and be temporarily up and running... -

Need part for Chinese patcher

drumminor2nd replied to drumminor2nd's topic in Leather Sewing Machines

You're welcome. I was in a bit of a rush to get the emailed pic (with a webcam) off to the seller. Had a chance to find a ruler and my iPhone. Sorry about that! I figured I'd give this bad boy a try -- I've been looking for an old Singer 29 patcher because I have an amazing local shop owner on the main street of town who can work on anything (my mother, a former seamstress, swears by him and won't let anyone else touch her machines), but I haven't found one cheap enough to bite on yet. This will hopefully get me through for a while, help me stitch up some stuff to sell and eventually pay for a better machine. -

Need part for Chinese patcher

drumminor2nd replied to drumminor2nd's topic in Leather Sewing Machines

I'll try -- bought it on eBay from a US-based seller. The product description said 3-day, but it was shipped ground. Figure between the two I may have some leverage. Other than the one part, it appears to work just fine. Bit rough finish (to be expected) and I can't get the smell of the grease off my hands now, haha, but it seems to be overall pretty smooth in operation. I was looking for something to do short runs, and I think this will work if I can ever get the darned part... I can see why people say to ditch the included tripod, though. My goodness what a piece of junk! -

So I just received a Chinese patcher (two weeks after ordering despite "UPS 3 Day Select" as the shipping option), but the part identified in the manual as "Needle Bar Connecting Link" arrived in four pieces. Not wanting to screw with a return, I'm going to see what all needs to be replaced on it (and ask the seller to chip in). It appears to be the part that connects the upper arm to the needle shaft (thus making the needle go up and down). Is this the right replacement part? http://www.bantamsaddletack.com/Linker-Arm-for-Patcher-Sewing-Machine_p_62.html Also, anything else I should look for to make sure this thing is otherwise functional?