-

Posts

68 -

Joined

-

Last visited

Profile Information

-

Location

Nowra, NSW, Australia

LW Info

-

Leatherwork Specialty

Beginers

-

Interested in learning about

All aspects of leather work

-

How did you find leatherworker.net?

Web Search

Recent Profile Visitors

3,290 profile views

LomaeArts's Achievements

Member (2/4)

-

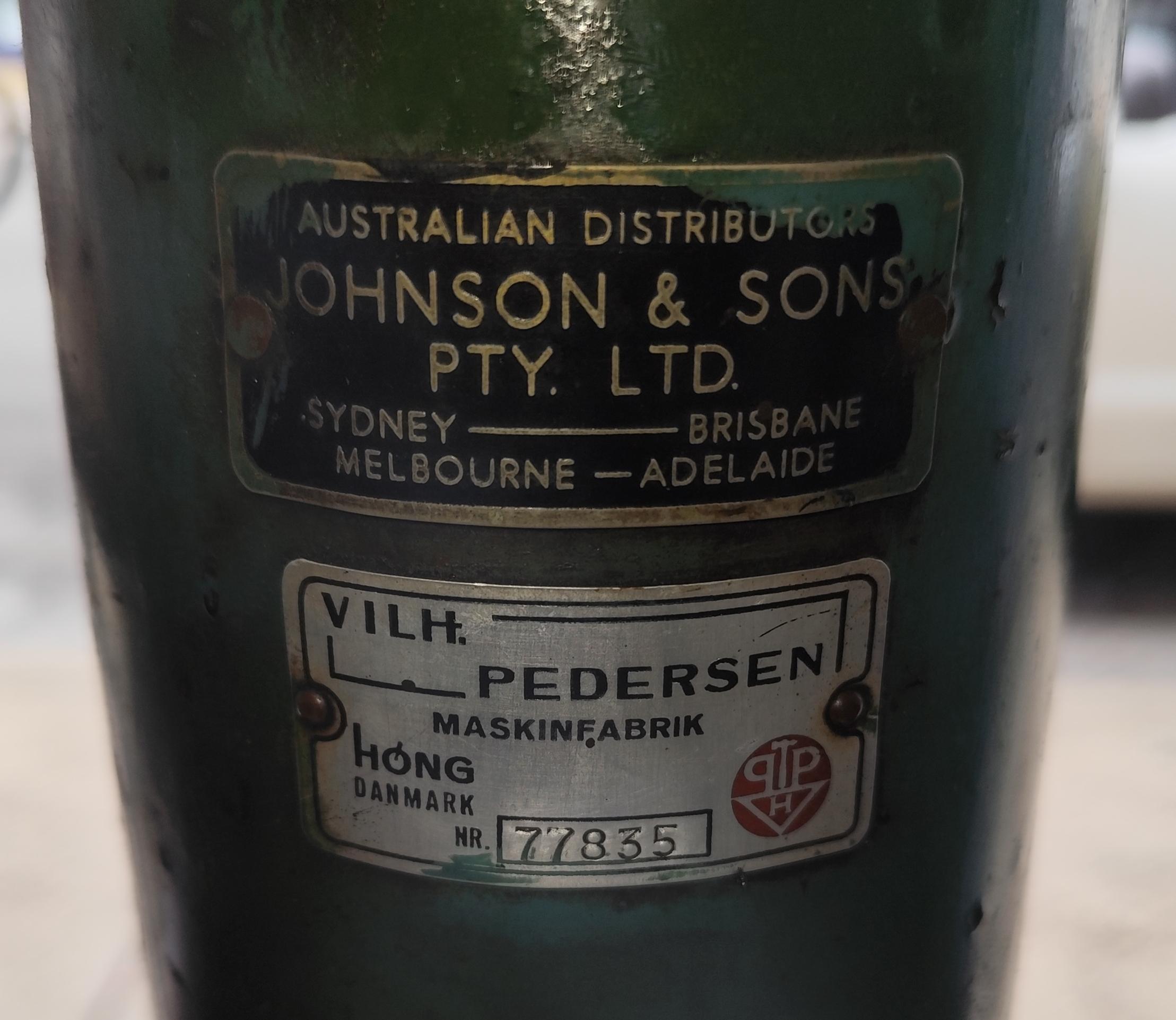

We have a Vilh Pedersen chain insole stitcher. We use it as bought 3 or 4 years ago. I would love to know if I can change the stitch length from about 6mm to 12 to 15mm. I would also love an operating manual if they exit. Thanks Matthew

-

Some of the youtubers we follow have neat toys to make processors better/quicker. One such item I drool over in the Campbell Randell Variable Speed Burning Machine. Chances of getting one in Australia are pretty minimal and if it was available, I would probably be hit with a 50% export Tariff ;). So I after some time on my CAD I came up with these. The sanding wheel is 89mm diameter and has a small flat area so the sand paper has a slight overlap and you don't feel a bump. I choose the diameter to suit strips cut from an standard sheet of wet and dry sand paper. Currently I am testing 180 grit and am extremely satisfied. The Dust collector is NOT my work. I blended a vaccy adaptor on Thingiverse (https://www.thingiverse.com/thing:2806410) to suit my needs. The burnisher works well. These are all printed in PETG and time will tell if the stand up to abuse. Both the sander and burnisher are driven by 1/2hp 3 phase motors with VFD to control speed. When I get this mounted in their (yet to be designed frames) I will share moer details. As always I am very open to comments and observations.

-

Thought I'd give an update. the molds were an overkill. the outer mold is not needed.the Cutting and marking guides are useful as is the internal mold for gluing. using the angle gring to remove a portion of the grit can have variable results, particularly if I go a bit heavy hand ( as Ray says," I love my job I get to do it twice!"). I made 3 coves using the 80grit Diablo paper and have barely worn 1.

-

We needed some breaster cones for the finisher. Both local supplier here (Rihanna Footwear and Leffler) don't have our size. So I made some with a little math help and my 3D printer. The first one was glued with super glue, I will move to high temp epoxy if the glue fails. Yesterday I pushed about 20mm of 6mm sole leather into it. I need to work on the joint as I can feel the bump.

-

Female Hinges for a Singer 112w139 Sewing Machine

LomaeArts replied to tmitch's topic in Leather Sewing Machines

Super old thread however for those in Australia these can be sourced at https://marfar.com.au/ Hinge Plate: SIN-202259 | Singer Hinge Plate Hinge: SIN-210844 | Singer Machine Hinge 202258 -

I am abour to embark on cleaning up a couple of Frobana sole stitchers. The units are pretty dirty and I want to repaint them. Does any one know the pantone colour code of the red and text paints? I also need to update the power cabling.

-

- 6 replies

-

- singer

- double needle

-

(and 1 more)

Tagged with:

-

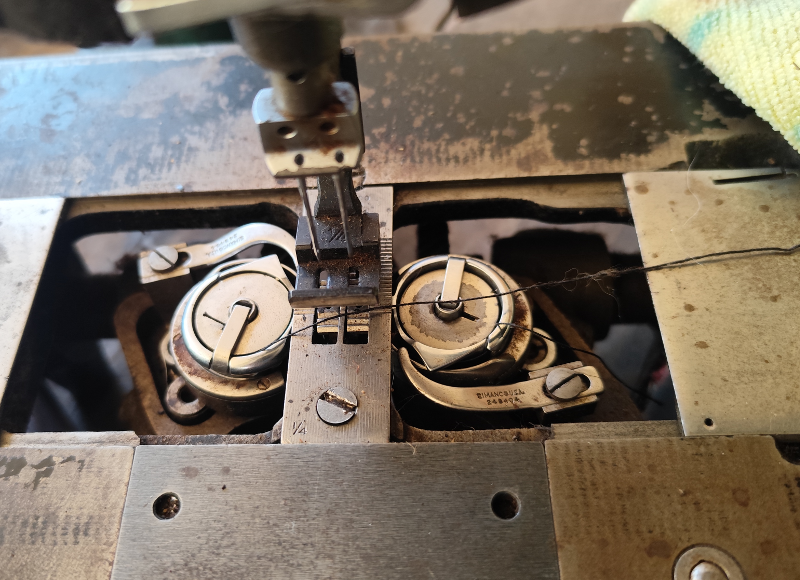

Being is a rural area, we get a reasonable number of requests to repair horse blankets. Most of the time our Singer 20U is sufficient. Recently I acquired a Singer double needle. It only has a serial number is the W913XXX range. ISMACS isn’t any help identifying the model number. A photo is attached. Can anyone identify the model?

- 6 replies

-

- singer

- double needle

-

(and 1 more)

Tagged with:

-

I spend most of last night searching for video I had seen. Well I came across this youtube this morning

-

I wonder if I can ask anyone with a working Model 308 could post some photos showing the position of the shuttle when the hand lever is fully extended up? Thanx in advance Matthew

-

A customer dropped this off today. he said he used to sew leather with it a while ago, but has been store in the barn for the last several years. I doubt it has been cleaned in a while and the cotton oil wicks were pretty dry. after oiling it, resetting the needle I got the needle to pick up the bobbin thread. is stitches OK but the tensions are shot. He applied paint in the wrong places. So if I decide to keep it, it will get a strip down and some TLC. a quick search on eBay shows parts availability is good. And I don't like the colour. Matthew

-

Ok finally got time to look at this again. The issue I bigger than I thought. I removed the feet and the needle hits the race case. I adjusted the race case so the needle doesn't hit it, but now the needle hits the needle foot. Man. I would love to know what they did! more reading and research is called for. Matthew

-

capturing a short video has raised multiple issues: the needle is be misaligned by the foot and also the hole. Tomorrow I will revert to the original binding feet and needle plate. https://youtu.be/Z4nBmquW2xg

-

RA, Will do. I also found the an adjustment manual for a Pfaff 335.

-

An employee recently acquired a good second hand, working a Golden Wheel CS 335BH, a binding cylinder Pfaff 335 copy. the binding attatchment has been replaced with a non binding kit. the shuttle timing has an issue, as the needle goes down into the shuttle race but jams preventing a full rotation of the mechanism. I have checked the shuttle and bobbin, there is nothing out of place. I haven't found a methodoly to verify the timing mechanism. Can anyone assit? I will grap a small video of the machine showing the issue today when I retrun to our shop.