KennethM

Members-

Posts

150 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by KennethM

-

Need advice on sewing across transitions

KennethM replied to KennethM's topic in Leather Sewing Machines

Thank you for the reply.I understand what you are saying.However I think its more a issuie with different leather thickness.Its the "step down" -

Hey everyone!I need advice on how to handle transitions and keep the stitch spacing consistent on those transitions..I sewed up a roper wallet.The wallet back is 5oz and the card pocket panels are 4oz.

-

Is this still for sale?

-

Hey everybody.I'm sure this has been done before.I remember reading a tutorial on it somewhere however for the life of me cant find it. I have a leather burning soldering iron with the temp control.I have been experimenting with diff heats on how to finish my edges more proficient.I am getting close but not right where I want to be. Has anyone used one of these tools for heatable edge paint?I am using vernis.If you have used it ,I would love your protocol and method.

-

I am about to get some barge for the first time.Switching from tandy leatherweld I think is what its called. I was curious do any of you guys use squeeze bottle for barge or do you prefer gluepot?Also if I use a squeeze bottle do you think it needs to be thinned?

-

Review TD-801D The king leather skiving machine

KennethM replied to shantiandd's topic in Leather Machinery

Man that's cheap!- 11 replies

-

- skiving machine

- splitting machine

- (and 4 more)

-

Review TD-801D The king leather skiving machine

KennethM replied to shantiandd's topic in Leather Machinery

Oh man thats a sweet machine..how much are they? Ps dont buy a techsew- 11 replies

-

- skiving machine

- splitting machine

- (and 4 more)

-

Thats a good idea off .didn't think of that.Thank you

-

I was using #69 thread with size 18 needle on my wallets. The outside panel is oz.The Knott always centered however I always had issues with corners and needles bending,etc So as of late I switched to #92 thread with size 20 needle.Now on 3oz naturally it seems impossible to center the knott however when all the panels of the wallet are together it works great.However on most of my bi fold wallets.the upper outside panel has a decorative stitch.So if you were me what would you do since the Knott doesnt really center. Would you just make the outside look great and let the Knott rest on the bottom side?. In the future I may switch to 4-5oz for the otter panel and lighter oz for the inner however right now I cant do that.

-

https://www.dropbox.com/s/sthq279elkx3wa8/0114191453.mp4?dl=0

-

Here's another issuie I am having https://www.dropbox.com/s/sthq279elkx3wa8/0114191453.mp4?dl=0

-

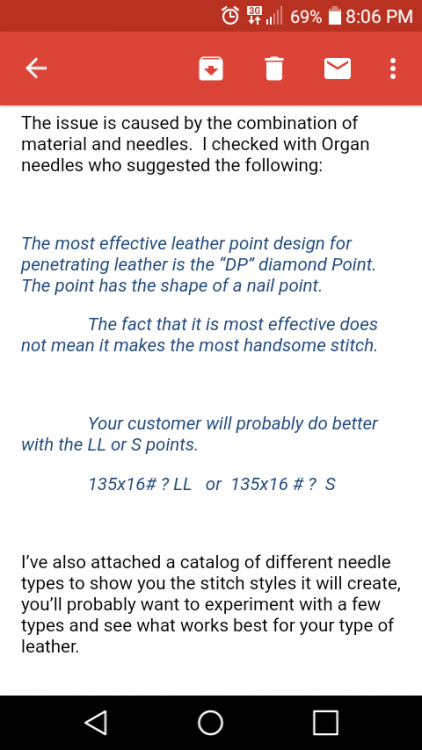

So far techsew has not been the greatest help per say.. I sent them photos of the wallet asking for advice on what went wrong and how can I fix the issue or avoid the issue .As I am having the ssme problem on every wallet regardless of needle. Mind you my needle stitch lenght is not accurate either..this is what they email me.

-

Update: So I had some free time today.Trying to figure some things out.Techsew techsupport is looking into my emails I started following the sailright sewing machinw manual to try to figure some things out I first at trying to proplery balance the pressure feet alternating height So I set the otter pressure goot to lift 4mm and the inner to lift 2-3mm per the sailright manual. Then by hand I did a stitch per inch test. I noticed going forward I am now more consistent of about 7 Mm but the last puncture looks to be closer to 8 mm. Then when I go in reverse and pray that I go through the same holes ..well I dont I make new stitching holes..check out this photo.. All and any help is welcomend

-

Yes thought I fixed it..guess I didnt do it properly

-

I did a paper test.I used the hand wheel to check my stitching spacing and its off.I'm not getting correct stitch spacing. 1)why is the happening? 2)how do I fix this?

-

Got a questions for everybody since I'm new and still learning about sewing machines. Shouldn't the needle and middle foot touch the material your sewing/feed dog together in sync?Becuase mine do not .

-

Ah that makes sense.Thank you

-

Ill have to keep this in mind and double check.I was using #69 with a 18 needle but just bought some bigger needles for #92 thread Can you explain what you mean when referring to consistency and sewn face up?

-

Thanks man.I thought I was doing this but perhaps I did bring the needle up enough

-

Thank you I will keep this in mind..not sure my needle point type.I just bought some new bigger needles. How do you turn corners with no tension realse Thanks Ron.The pressure foot would stick before I switched them out,they still stick matter of fact but will give them a email.

-

Hey Matt I am using leather spefic needles.But thank you. I am glueing my leather.Using E600..I was using leather cement from tandy but I wanted to try something different. I have the pressure feet as lose as possible when this was sewed.I suppose I should have practiced on a scrap for 3 layers.I did a practice run for 2 layers and it was perfect.Thank you for the tips I will try this out.I'm confident its fine tho!

-

Hmmm..maybe I'm not sure lol.Need someone smarter then me to confirm

-

I been having this issue on every wallet I try.I recently bought my first sewing machine.A techsew 1460..When I see my wallets the top side looks great.However the bottom side is horrible.Especial the corner look bad on the bottom side.When I approach a corner I hand wheel it untill I get to the turning point.Leave the needle in then use the knee clutch and then rotate my work. I am using tandy leather.2-3 oz..I didnt skive this leather.Using #69 thread with a size 18 needle 135x16 needle system...please help..burned about 10 wallets.I have tried different pressure feet pressure combo.New needles..nothing has helped..its always the corner and the back side of my wallets. https://www.dropbox.com/s/iq6fiyji5uwcfdu/0109191541a.jpg?dl=0 https://www.dropbox.com/s/ysifjlgakmb9s8w/0109191541b.jpg?dl=0 https://www.dropbox.com/s/ku0bafeeqmplao1/0109191541.jpg?dl=0

-

Hello everyone.Hope everyone is having a great new years.My nephew got his first riffle for Christmas.A Remington 770 308.I want to make him a Ammon butt stock carrier. I think I have a idea on how to do it but could use some advice.Here is what I was going to do. Use 6 oz veg tan ,that's the total is..2 ,3 oz panels. Trace the stock on some paper for my pattern.Tool the top layer.Add my eyelets.Then glue that layer on to another layer so the eyelets wont scratch the stock. I was going to cut a strap and some slots out .Then weave the strap in and out the slots for the Ammon belt. Some questions.. How do I figure out how far apart to add the slots for the ammo. Do you guys add extra room on the pattern for the leather thickness?