DanishMan

Members-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DanishMan

-

It may also be horizontal oscillations, that requires two nuts at the end of the knife shaft to be tightened. Brgds Søren

-

Completed the machine today. Will bring it to a friend next week. He is a sewing machine mechanic with 55 years of experience. We will fine tune it together

-

Thank you Castle I have another skiving machine arriving from Poland on Tuesday. Cheers

-

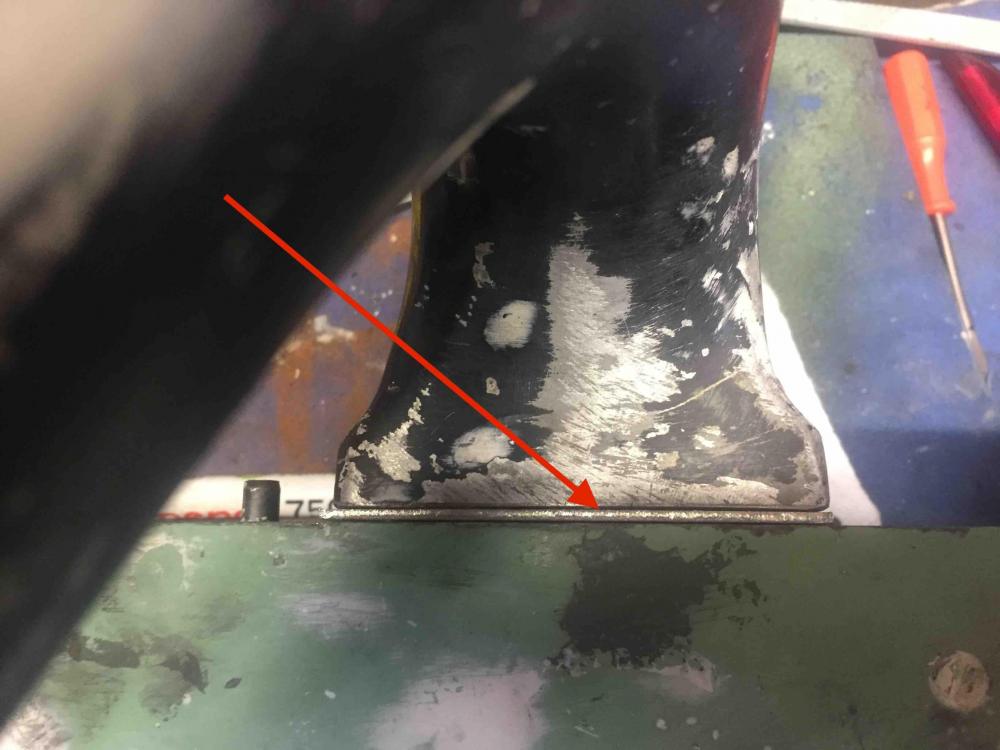

Today, I spend several hours grinding - to fit the new arm to the Fortuna 3S skiving machine. To be able to use the arm, I had to fit a 2 mm metal plate between the arm and the machine. For that reason I had to enlarge the hole to make the shaft going through the arm rund freely.

-

Good morning Falseyellow How did you adjust the position? The arm has alignment pins or? Cheers DanishMan

-

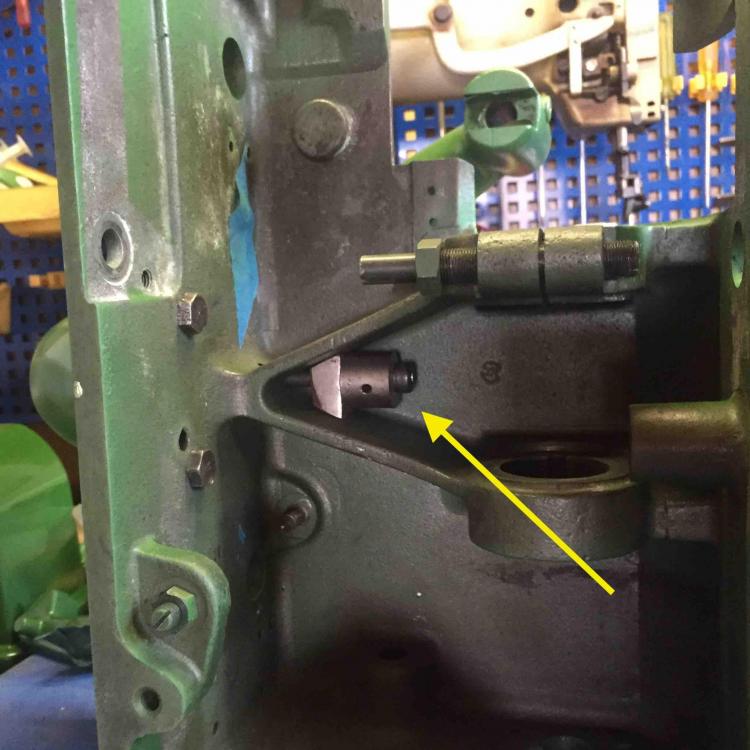

Starting to put the machine together today. As mentioned earlier, I had taken the huge 3S arm off the machine. The plan is to fit an arm from a older Fortuna machine, that I bought last year. The 3S arm was attached to the machine with four big bolts, whereas the normal arm is fitted with three bolts. For that reason, I had to drill three new holes. One of the holes went through the structure holding the knife shaft. I had to make a wedge with a hole through it. For that I used metal from the big 3S arm. To make the bolt fit, I also used a piece of of metal from an old skiving machine handle. The transport wheel shaft goes through the arm. I had to make this hole slightly bigger by using a dreamed tool. Tomorrow, I will keep putting the machine together.

-

Hi Cumberland Considering the amount of time going into this, it is not worth the money - compared to having a job. But right now, I am not working due to corona, so it fills out my day. Besides, very few people in Denmark know anything about skiving machines, so maybe within time I can build knowledge, that could turn into a small business. Kind regards Danishman

-

Hi Jimi I will just have to let the paint harden for a few weeks. Then I will start assembling the machine again. I had to fit a 2 mm metal plate between the arm the machine. I also had to drill new holes, as the arm is attached with three bolts, whereas the 3S arm had four bolts - but I think, it will work out. Cheers Søren

-

-

I paid 1000 dkr - which is about 150 USD. Cheers

-

Hi Jonas I grew up in Aalborg, but now live close to Copenhagen. Cheers

-

Durkopp 241-5 needle bar centering

DanishMan replied to DanishMan's topic in Leather Sewing Machines

Thank you Folker. It makes sense. Cheers DanishMan -

Durkopp 241-5 needle bar centering

DanishMan replied to DanishMan's topic in Leather Sewing Machines

The needle is 0.5 - 1 mm off (it's a machine of a friend of mine) I will ask her to change needle before trouble shooting further. Is it possible to move the needle bar frame sideways? I have not found any guidance on that in manuals for Durkopp, Singer 111, Consew 225. Kind regards Danishman -

Dear Friends Could anyone here help me with adjusting the needle bar frame - in order to center the needle in the feed dog? Kind regards DanishMan

-

Hi Jonas The Thyregod color is very nice, but in fact the original colour is even darker. I see that you are Danish. Where do you live? Cheers Søren

-

-

Before painting the machine, I have to make sure, that the black arm fits this machine. I realised, that I had to mount a to mm plate between the base of the arm the the main machine. I do not have this peace of metal, but I will try to get in on Monday. Next I have to make sure, that with the black arm, the presser foot will be situated properly over the feed wheel. It turns out, that the presser foot will sit 1 mm back compared to my wifes Fortuna. I believe it will work. The original 3S machine had a 34 mm roller wheel, and I want to use a 50 mm wheel instead. This requires only minor adjustments it appears.

-

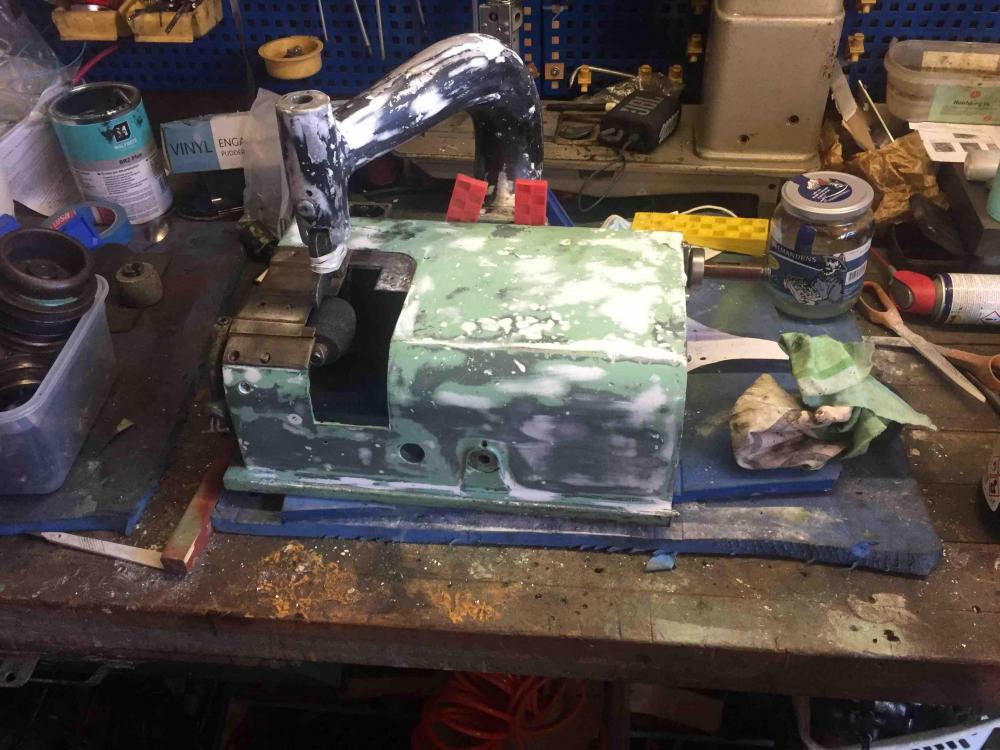

Resada green is too light (I used that before). Instead I ordered Thyregod green, which is darker. And you are right - preparing for painting is a pain.

-

-

I have ordered Esbjerg machine paint today. They have a green, that is very close to the original paint. Regarding hammerite paint, it takes practice, and one has to use a thinner - otherwise the paint becomes a powder.

-

I painted two of them with hammerite paint.. It takes a bit of practice to get a good result. And still, it is not as strong as the original paint. I suspect, that the machines are "baked" somehow after being painted..

-

I finished this machine a week ago. An old Danish machine. I fitted it with two motors - one big constant speed motor for the knife, and a servo motor for the roller wheel. It works really well, as the skiving speed is from 1cm/sec and up.

-

By the way - I have worked on several skiving machines during the past half year (due to corona) - all of them have been produced in Denmark by Vilhelm Pedersen

-

I have taken the machine completely apart. Normally I only do this, if I have to paint the machine. This one has been brush painted with a light green, so I will definitely have to paint it on the outside. The inside is very smooth. My experience with painting an old machine is, that the original paint is usually very sticky and more durable than new paint, so the plan is to putty fill the machine and then sand paper it. Tomorrow, I will also measure, how to fit the black arm from an older machine.

-

Fortunately I do not have to drill treads in the three holes. I could probably make them a fraction bigger, than the bolts, and then use a pin to make sure, that the alignment gets right. I will post more photos later