DanishMan

Members-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DanishMan

-

-

-

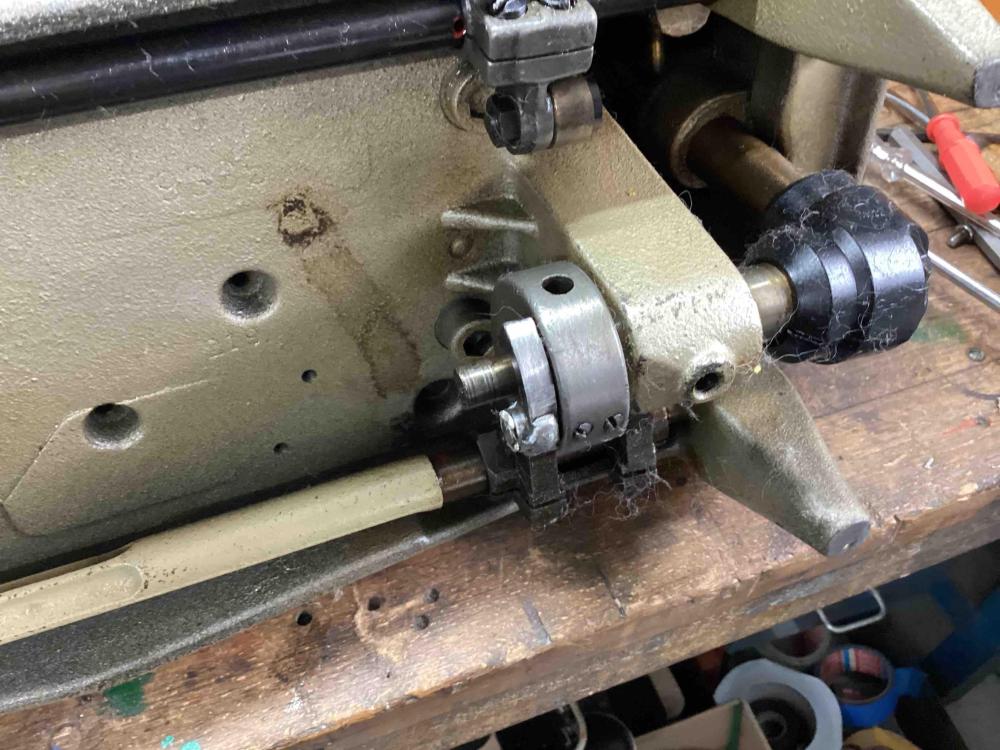

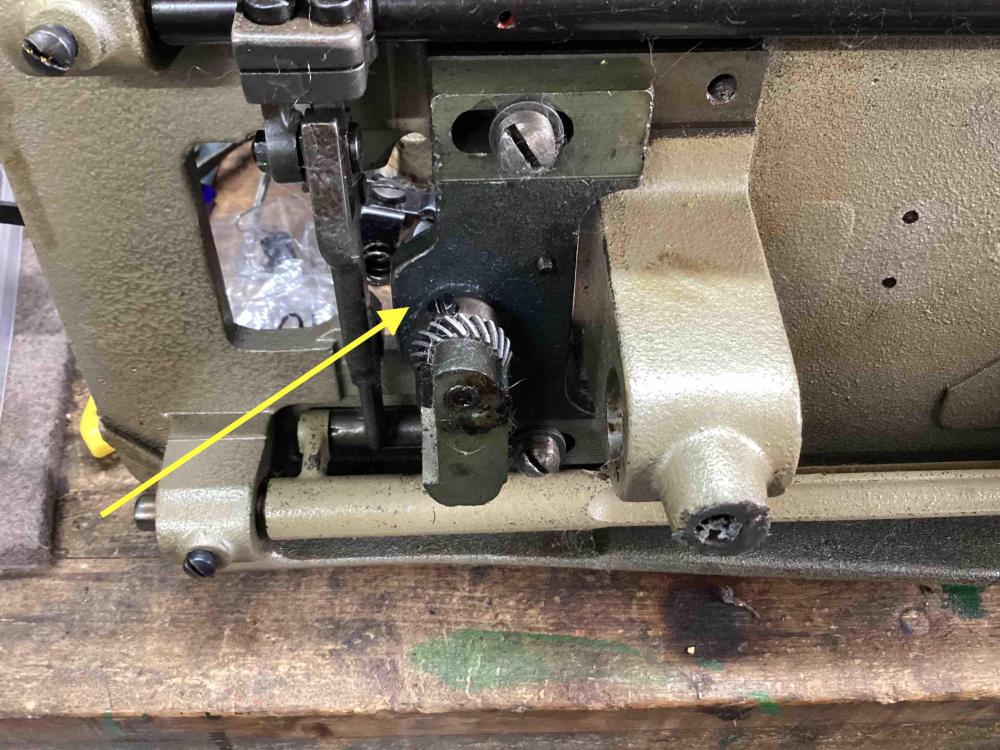

I will part of the 543 and use the following parts from the 543 The eccentric of the 543 including push rod. The hook saddle holding the bobbin case of the PFAFF 543

-

Dear Friends On a Facebook forum about industrial sewing machine mechanics somebody recently asked, if it was possible to change the bobbin case of a PFAFF 145 to the larger bobbin case of a PFAFF 545. I have done this on two 145s a few years ago, and it is a fairly simple process. I have decided to replace the bobbin case of an old PFAFF 145 with the bobbin case of a PFAFF 543, which is also used on the PFAFF 545. At the same time, I will use the extra eccentric of the 543, which enables the four-motion feed of the feed dog. The PFAFF 545 does not have this movement, but machines like the PFAFF 1245, 1445, 1525 etc have this feed dog motion. PFAFF 145 and PFAFF 543

-

Dear Friends For the past 5 years, I have restored 15+ skiving machines. Most have been Fortunas, but there have also been Danias, Vilhelm Pedersens, KAEVs etc. Right now, I am working on an older Fortuna, which I found in Poland. The machine was complete, but one part was not original. I am looking for the arm, that direct the belt for the grinding wheel. I have enclosed two photos. They are not of my machine, but of another Fortuna machine, which shows the missing part. If anyone has this part as a spare, I would like to buy it. Kind regards Danish Man

-

Dear Friends I am looking to buy a PFAFF 1445, but I find it difficult to interpret the number plate. On the first line it says 1445 706/07-900/56 Below it says 901-1445 02/015 I am pretty sure, that the "901" refers to the trimming function. Does anyone here know the maximum stitch length and how much material can you put under the foot. Kind regards Danish Man

-

Hi Keegan I have taken 15 skiving machines apart over the last couple of years. I am not quite sure, what you mean. Do you mean, how to remove the scrap ejector? Cheers Søren

-

It should be fairly easy to replace this spring.

-

When I started working with skiving machines, I sometimes used leather straps. Now I use a 6 mm polyethylene belt. Much easier - you can weld the strap together, once fitted and it does not get longer with use - as is the case with a leather strap. Brgds Danishman

-

It looks like a Sagitta

-

It is actually a Durkopp 1767 - my mistake.

-

Hi Volker But when the hand wheel gets stuck she can just touch the foot pedal, and the machine sews. Probably something in the hand wheel. Cheers Danishman

-

Dear Forum A friend of mine has a Durkopp 176 sewing machine. A machine I know nothing about. Se has a problem with the hand wheel. The machine works perfectly well, using the foot pedal, but when turning the hand wheel manually, she can rotate it just a few centimeters before it gets stuck. Any idea og what the problem might be? We do not live in the same city, and I have not had a chance to check the machine for real. Brgds Danishman

-

Thank you Glenn I will try to contact him. Cheers Soren

-

Dear Friends I have a question about how to adjust a Quick Rotan motor. It is not for a leather machine, but for a Union Special 34700. However the Quick Rotan is also used on many leather sewing machines. When I got it, the thread trimmer and foot lift did not function (powered by a magneto). After replacing the carbon brushes, the foot lift magneto is back to life. However, the sequencing is off: When pushing the threadle, the presser foot goes down, and the machine starts to sew. When releasing the threadle, the needles stop in down posistion, but the presser foot goes up. When healing, the threadle, the needles go up, the presser foot goes down, and the trimmer activates. Then the presser foot goes up again. Anyone here, that have experienced a similar problem - or anyone that has a Quick Rotan instruction manual covering adjustment og the magnetos? Kind regards Danishman

-

Pfaff 145 h3 reverse stitch length shorter than forward

DanishMan replied to ThomasBH's topic in Leather Sewing Machines

I made this video two years ago. At that time I used bottom dead center as reference for the feed dog not moving. Now I changed it to 1 mm up again. Regarding the piping feet. Are they original? -

Pfaff 145 h3 reverse stitch length shorter than forward

DanishMan replied to ThomasBH's topic in Leather Sewing Machines

Hi Thomas The mismatch between forward and reverse stich length is most likely due to the lower transport not set correctly. Set the stich length to zero Rotate the hand wheel in the normal sewing direction and take the needle to bottom dead center (all the way down). Now continue rotating the handwheel and raise the needle slightly less than one millimeter. When moving the stitch length lever up and down, the feed dog should not move (or just very little). If is does move, adjust the eccentric on the main shaft (close to the handwheen). If this does not solve the problem entirely, you can play a bit with the eccentric. Regarding the two additional questions, I am not sure about the size of the screws going into the metal cover.. May be it is easier to find new screws than a different cover. I am not sure, what you mean with the second question. Could you possible take a few photos? Brgds Danishman -

Hi Amando It is pretty much a Fortuna 801 clone. If you find the manual for a Sunstar skiving machine, it should work. I would only paint it, if it is really ugly. On the other hand, if it is a project, why not. I have painted a few skiving machines. Rather than grinding it all the way down, I have used filler and sanded them. The original paint is much stronger, than what I can achieve. Therefor I find this to be a better solution. Brgds Danishman

-

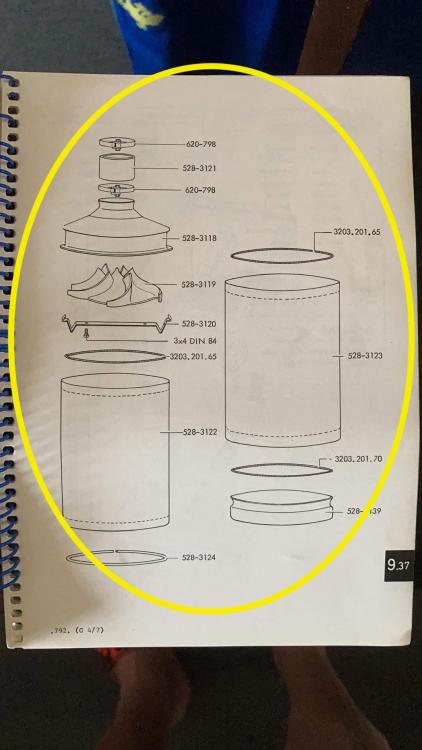

Dear Friends I am restoring three Fortuna skiving machines.. One is completely missing the vaste bag (Staubsack) assembly. Anyone here, that has this for sale (complete). Brgds DanishMan

-

Hi John I have painted a PFAFF 335 and four skiving machines. It is not easy................................................................... The 335 and the first two skiving machines were grinded down completely - then primed before using hammerite paint. The result was okay, but the paint is not as strong as the old paint. On the two last skiving machines, I did not remove the original paint. Instead I used putty filling and then sanded the machine, before painting. I did find the result to be better, and the paint is stronger. I have taken several PFAFF 145s apart. It is fairly simple. It can be a major challenge to remove the main shaft. Be very observant of any burrs a the hand wheel. You have to remove any burrs - otherwise, it can be almost impossible to take the shaft through the machine. Also you have to be carefull, when removing the pick up lever - It can only be removed from one position. Kind regards DanishMan

-

Probably better to take it the other way. And fit the new one, while removing the old one. Cheers

-

Pfaff 545 bobbin case opener jams the catch hook

DanishMan replied to John D's topic in Leather Sewing Machines

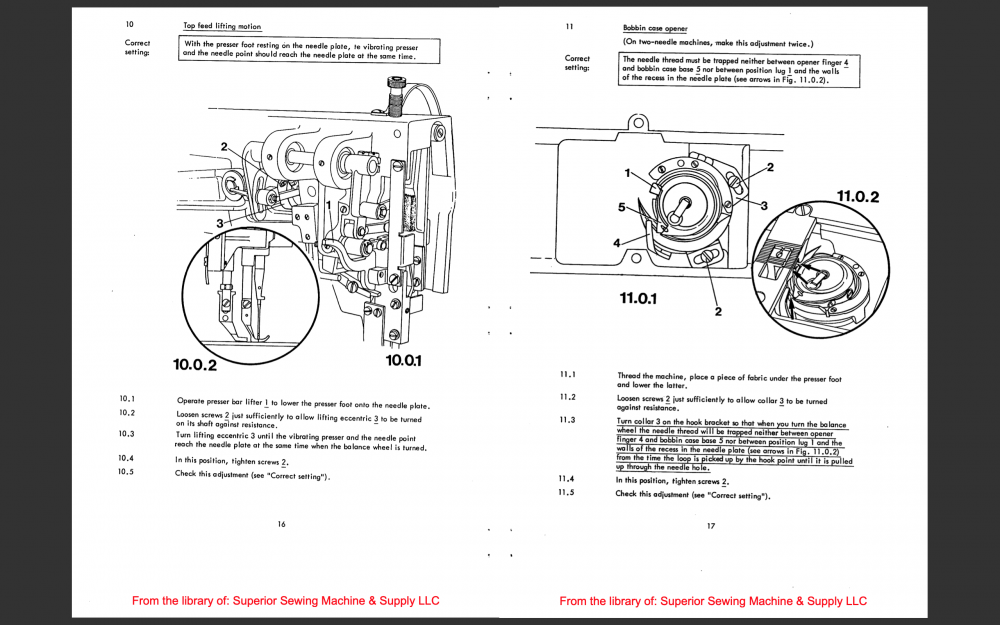

The 145/545 only has one screw to adjust the bobbin case opener. The 1245 has two, but the principle is the same. This is from the 245/1245 service manual. -

Pfaff 545 bobbin case opener jams the catch hook

DanishMan replied to John D's topic in Leather Sewing Machines

I guess you have to adjust the bobbin case opener. -

Hi Hugocraft Sorry for my late response. If you just remove the presser bar, the metal balls will fall out. 91-019 657-05 is housed inside 91-019 656-05. It has been a long time since I did change the metal balls of a machine, but I am going to pick up a 145 on Monday. As I remember the ball size is 1/16 inch. You can probably retain the metal balls inside the ball bearing part, if you insert a temporary piece of the same dimension as the presser bar. Cheers Søren

-

Fortuna model 10 skiver parts availability

DanishMan replied to AlizabethThomas's topic in Leather Machinery

Could you possibly take a photo from underneath. It is difficult to assess, what is missing. Kind regards Soren