DanishMan

Members-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DanishMan

-

Hi Jimi It is easier to find PFAFFs - especially machines that have been used in industry. Later today, I will drive to a smaller town in Denmark, where a couple bought a shoe factory four years ago. Everything stored in a barn. Might be some interesting stuff. From the pictures I can count four post bed machines, a PFAFF 353 (left hand), and a PFAFF 27. Supposedly there is also a skiving machine somewhere. Take care. Søren

-

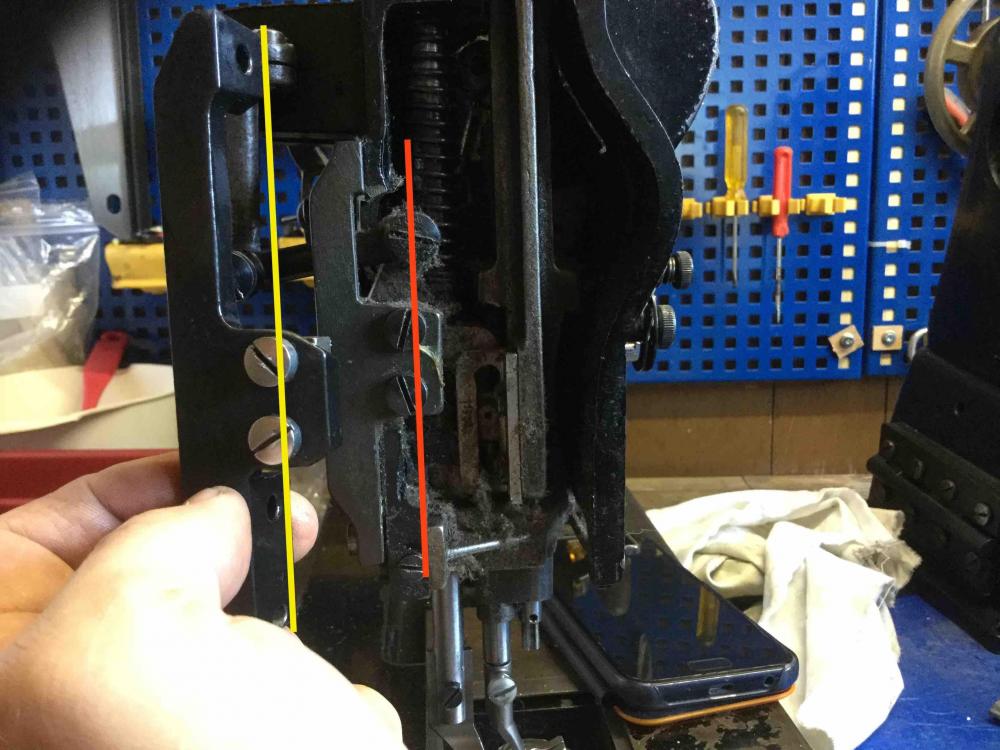

Next problem. When I bought the 335, it was incomplete. One of the things missing was the "Presser bar guide block bracket". As I had three from old machines, that I have scrapped, I did not expect this to be a problem - I painted one of the three brackets black. Now it turns out, that this bracket is shorter on old 145, 335, 345 machines. As can be seen on my old black 145, the bracket is shorter (9.9 cm versus 12.3 cm on newer machines). If anyone has the short bracket in stock, I am interested in buying it. Brgds DanishMan

-

No P model so far.

-

At the moment I have One 145 One 331 Two 335 One 595 One 143 One 543 Four skiving machines

-

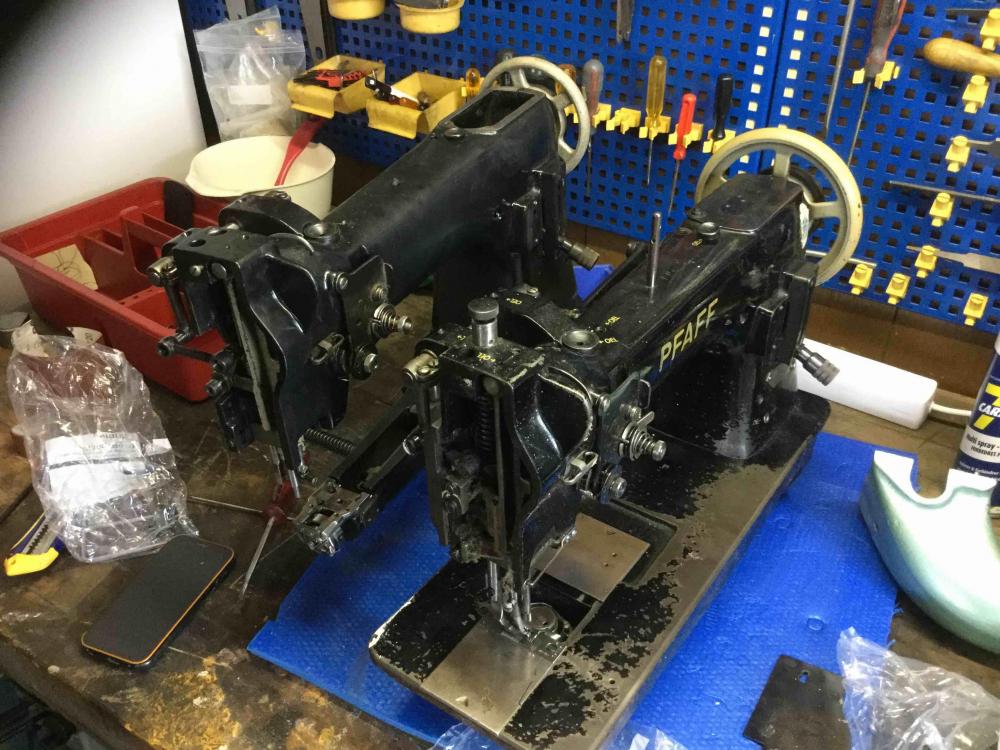

No much progress with the 335. The foot pressure regulating mechanism is broken. As it is a different size, than on later 335s, it is almost impossible to find. Now, I am talking with an instrument maker, and he can probably fix it. I am just waiting to see, if the price will be reasonable. Meanwhile, I received a PFAFF 145 from Germany today. For once, packing was excellent. This old 145 in fact has the same part, which is damaged on the 335. However, I am not going to part out the 145, which appears to be in perfect working order.

-

Ohh - very nice. I do not have a 3D printer, but it seems nice.

-

https://www.youtube.com/watch?v=a-wRn4DO-Nk I just fine tuned my 331. The only thing I am missing, is the hook cap, which is a different size than on the 335. Any idea, where to buy one of those. Kind regards Danishman

-

I will make a video in a couple of hours. The 331 has the extra eccentric, that allows for the oscillating movement

-

I have a PFAFF 331. While it does not have alternating feet, it has the oscillating feed dog. One can quickly swap between a normal foot and a roller foot, which makes the machine very versatile for smaller things.

-

Slowly putting things back together. Still missing the presser foot regulating mechanism. Also need to figure out if thread tension can be released via the foot lift.

-

-

The 335 project is slowly progressing. When I received the machine, the needle bar rocker was broken in two pieces. I wonder how that can happen? However I managed to find another needle bar rocker - one of the old ones with a thin needle bar. The next and bigger problem is the top screw mechanism, which regulates the foot pressure. It too had been broken (due to poor packing). I have searched everywhere, but this turns out to bee nearly impossible to find. It is much thinner and more fragile, than on newer models of the 335. I believe, I have seen it on early 145s, whereas almost all other PFAFF models features a screw which fits threads in the main structure. The problem with the take up lever is sorted out. The pin, which attaches the "pendular" to the main shaft in the front part of the machine was damaged. A replacement pin sorted that problem. So now, I will just keep looking for parts. As a matter of fact I bought a derelict 335 two days ago, but after cleaning this machine turned out to be in very good shape. This will not be used for spares.

-

Searching for spare Parts Pfaff 335 H2 L

DanishMan replied to MacB's topic in Leather Sewing Machines

Hi Mac Did you find a needle bar rocker for your 335? I am looking for two - one for a 145 and one for a 335. I am thinking of ordering in China - when they open up. However, I would like to hear about the quality of the China parts. Kind regards DanishMan -

By the way - it is not a bolt going into the take up lever - it is a pin.

-

Hi Shoepatcher I recently bought an old machine in Germany. It was supposed to be an old 145, but it turned out to be a 142 - (there was only photo, that did not show the entire machine). Now it turns out, that I can use many parts from this machine. Today I salvaged the main screws, which are a fraction smaller than on later machines. Also the screws attaching the stitch length mechanism, are of different size, than on later machines. I was puzzled, as my machine was originally green - but probably an early one. The ones from the black 142 also fitted my machine. I encountered another problem, that I was not able to solve.. The original main shaft was bend, and I replaced it with the main shaft from a newer 142, that I bought last year (for only 15 USD). Everything went fine, until trying to fit the take up lever. The machine rotates smoothly until inserting the bolt into the take up lever. Then something goes wrong, and the take up lever causes too much friction. I tried to replace the bolt, the take up lever and even the main shaft. Same result every time. Any suggestions to the nature of the problem? Kind regards DanishMan D

-

I am putting the newly painted 335 together again. However, I encountered a problem. When taking the machine apart, I had to ruin the four main screws, as the were rediculously tight. When try to use main screws - from a PFAFF 146, they do not fit. Are there different main screws - with different threads? Kind regards DanishMan

-

Yesterday, I spent the entire day on the PFAFF 335 I have never painted a sewing machine before, so I am still in the learning phase. After grinding down the machine a couple of weeks ago, I primed it with Hammorite primer. The result was pretty good, and after sanding it with fine sandpaper the machine was smooth. I then decided to use silver metal hammorite using a brush. The result was not good, as the layer became too thick. I sanded the machine, and then sprayed it with black smooth Hammorite. The result was very good - or so I thought. After leaving the machine for two weeks, I started working on it three days ago. I had to remove a two screws, that had accidentally been painted over, and the surrounding paint came off in small flakes. When I sanded the machine before the black paint, I also partly removed the primer. Now what to do??? I saw no other way, than to start all over again. It too almost three hours to remove all the pain - using a bench grinder, a drilling machine with a steel brush, and a dremel with a milling drill. Before priming it i used a gas burner to remove water in the cast metal. Condensation is also a likely reason for paint not sticking properly. Then priming it two times, and now ready for applying black paint again.

-

Hi Jimi Yes I did

-

I had second thought about the painting, so I started all over again. The paint tended to flake off. Using my bench grinder.

-

Hi Jimi I had a similar 335 with only one hole to attach the side cover. I drilled two more holes and fitted the lifting device with the power exchange. I am not sure though, that I will do the same on this one. I will take a look into the JB Weld. I have never heard about it. I will post a few more pictures tomorrow. I am happy with the outcome of the painting. Take care Soren BattleAx and Iron1951 Thank you for your inputs

-

Today I have been working on a PFAFF 145, which I am converting into a 545. I still need some parts from Germany, but the should arrive soon. Secondly I have been looking at the 335, which I painted about three weeks ago. The painting was overall very good. As mentioned in the beginning, the machine has a small damage. It is an old machine, and the side cover is attached by only one screw, whereas most newer machines has three. As can be seen on the photo, the structure has been damaged around the screw hole. Is it possible to repair this at all? Brgds DanishMan

-

I have come across a PFAFF 305 for sale. Anyone here, who knows if parts are mostly the same as on older PFAFF 335s? Brgds DanishMan

-

Servo motor suited for pneumatic foot lift.

DanishMan replied to DanishMan's topic in Leather Sewing Machines

What is the quality of Ho Hsing? Brgds DanishMan -

Servo motor suited for pneumatic foot lift.

DanishMan replied to DanishMan's topic in Leather Sewing Machines

Thank you Shoepatcher -

Dear Friends Do any of you have experience in fitting a servo motor to a sewing machine, that has pneumatic foot lift. If yes, do you have any suggestions for which motor to choose. Kind regards DanishMan