DanishMan

Members-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DanishMan

-

Searching for spare Parts Pfaff 335 H2 L

DanishMan replied to MacB's topic in Leather Sewing Machines

I am looking for the same part. To be used on a Pfaff 145. This can also be used on an older Pfaff 335. It might be possible to use the part from a two needle 146 or 546 and change the needle bar. Brgds Danish Man What is wrong with the existing one? -

-

I think, I can use the service manual of a PFAFF 1293, but I am a bit unsure, of the how far after BDC, the hook should meet the needle. It is 3 mm on a 1293. Probably the same on the 593.

-

Dear Friends I have gotten hold of a PFAFF 593. It is in very good condition, but I thing the feed dog timing is slighly off. I would be grateful, if anybody on this forum could tell me how to adjust it. Kind regards DanishMan

-

On the next 145, I will try to change the stitch length also. Should be pretty straight forward. However, I would also like to change it from a H2 to a H4 (maximum thickness from 7 to 14 mm). How is that done? It seems as if the material thickness limit, is that the needle bar hits the vibrating presser, when going through thick material. Cheers

-

Hi Pintodelux I changed the hook saddle and the bobbin case (including bobbin case opener). I have not had a motor on the machine yet, but it seems to be sewwing nicely. Cheers

-

Last year I did find a sorry looking PFAFF 145 in a barn. Now - it has been cleaned up, and it is working pefectly. I also converted it to PFAFF 545 with a bigger bobbin case. Fairly simple operation. Brgds Danish Man

-

I orderend som 1/16 balls for the bearing. I hope they are not too dificult to fit

-

I believe they are 1/16"

-

Sounds a bit expensive to me.

-

-

Servo motor running rough at low speed

DanishMan replied to DanishMan's topic in Leather Sewing Machines

I just ordered 4 x 40mm pulleys at College Sewing. Thank you all for your advise. Brgds DanishMan -

Servo motor running rough at low speed

DanishMan replied to DanishMan's topic in Leather Sewing Machines

When I measure the shaft diameter, it appears to be 15 mm. The pulley wheels, I have located seems to have a hole, that is 16 mm. I suppose, they will fit. -

Servo motor running rough at low speed

DanishMan replied to DanishMan's topic in Leather Sewing Machines

Thank you Dikman. I will try and see, what happens. -

Servo motor running rough at low speed

DanishMan replied to DanishMan's topic in Leather Sewing Machines

I do not think, that a different size pulley will disable the synchronizer. I use the same motor on a PFAFF 1245, which has a bigger pulley, and this one runs much more smooth - and the synchronizer works very well. Brgds DanishMan -

Servo motor running rough at low speed

DanishMan replied to DanishMan's topic in Leather Sewing Machines

Hi Matt and Dikman Thank you for your replies. They calm me down a bit. The Zoje motor is not cheap, but I will try to fit a smaller pulley. Brgds DanishMan -

Servo motor running rough at low speed

DanishMan replied to DanishMan's topic in Leather Sewing Machines

Hi Gymnast Thank you for your advise. My be an option to use a smaller pulley wheen and increase the start up speed. Brgds DanishMan -

Dear Friends I recently bought four Zoje 750W motors with synchronizers. I have fitted them on three sewing machines. One thing, that puzzles me is, that when set to low speed (100 RPM), the motors run rough. Is this normal. Also the needle down function appears to be kind of abrupt. May be all motors behave like this at low speed - or may be I am not setting up the motor properly. Any ideas? Brgds DanishMan

-

Hi Campbell Randall The center hole in this machine is too small for that. May be it needs some kind of plastic deflector. Brgds DanishMan

-

Hi Katit Great to look your project to move ahead. I am about to take an old skiving machine apart and repaint it. Last year I tried to remove the main shaft of another machine, and it ended in disaster. You mentioned earlier in this thread, that it was tricky to remove the main shaft. What was the tricky part for you? Cheers DanishMan

-

Dear Friends Two months ago I bought an old skiving machine. Typical old Fortuna like machine I am a bit puzzled, that the machine has no scrap deflector. There is a tiny hole (5-6 mm) in the knife shaft with no threads - I have several scrap deflectors of both the common types, but neither fit. Are there skiving machines, that were born with no scrap deflector? Brgds Danishman

-

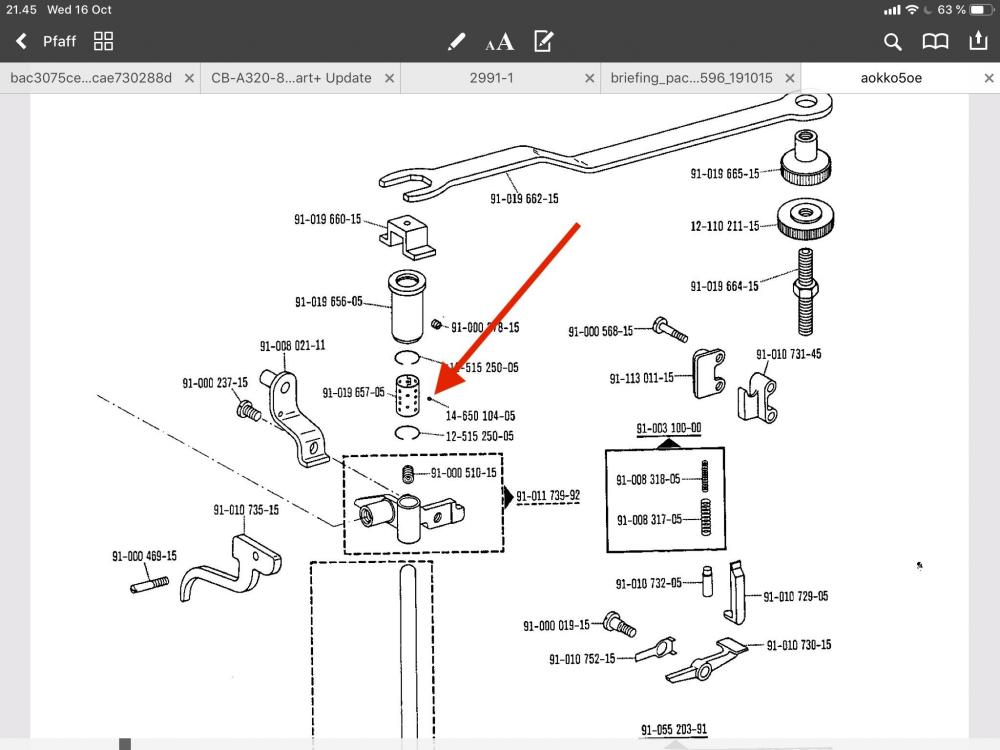

I think I solved the problem. The screw with the red arrow was extremely tight. Once released the shaft unjammed. Now my question is how to remove the knife shaft. Can I detach it (green arrow) and move the shaft all the way to the left and remove it? The last time I tried it on a similar machine, I completely destroyed it. Brgds Danishman

-

Hi Matt. The knife runs with no problem, but it is not possible to shift left/right. It is an old machine. Cheers Søren My other wreck project.

-

But will that cause the shaft to become completely jammed? Last year I wrecked a skiving machine by messing with the knife shaft (I wanted to take it out). I susptect that a rubber seal had jammed it.

-

Hi Matt and Scoutmom Thank you for your advices. I will try to do that. Brgds Danishman PS - I managed to move the knife shaft slightly more Yesterday evening