-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Smooooth

-

Singer 29k171 "Another journey to the unknown"

Smooooth replied to jimi's topic in Leather Sewing Machines

Is there any possibility that a write up may exist on this mod? I've given it my typical 15 to 20 minutes of searching with no results. Is this also similar to the leather pouch / cup / thingy that slips onto the lift lever? I like the two positions concept. Any videos if this in action (Simple YouTube search, NADA) I'm fairly sure I can grasp the concept. Thank you - I truly appreciate all this information. Pics are WIP. Motor now has a 45mm pulley and most everything has been finished. Last piece will be the vertical support for the table that is currently being laser etched. Stephen -

Pfaff 138-6 Looking for price and parts help

Smooooth replied to Scoutmom103's topic in Leather Sewing Machines

I know this is an old post - but I am now dealing with a gummed up ZZ mechanism. If possible - would like to figure out a way to live chat (maybe with video) sometime. Thank you!!!!! Stephen Moderator, Vintage Industrial Sewing Machines -

Yeah.............. I started there - but this is a more mature crowd (LOL) Thank you very much............. Stephen

-

Singer 180W201 1953-54 I have some research to do........ Not much out there. Was offered 'First Refusal' Original owner, fully functional. Only thing I have found is a Parts Manual. Not even listed on Ismacs. It does appear that one major difference compared to the 51W is that the 180W is belt drive vs the 51W direct drive. Having a difficult time associating a dollar value.

-

Thank you............ I will start with #69 and go from there - seems like a safe path. Stephen

-

Soooo....... If I understand you correctly. The same old 69 thread, Bonded nylon or Poly(?) (I mostly use 92) and the DCx27 in 16 or 18 will do the trick? Is 69 the typical safe MAX thread? Thank you Wiz - Stephen

-

Greetings...................... Hoping you are still around. Today I am picking up a MO-6716S FF6-50H. My primary purpose will be mostly sewing Sunbrella marine canvas. Just curious if you have dialed in yours any further. Looking specifically for what Needles (Size and Point) and thread size you have selected. Thank you, Stephen

-

I am still having a problem finding good reference pictures to be able to answer your question. Arrrrrggggghhhhhhhhhhh..............................................

-

Thank You Thank you

-

-

-

-

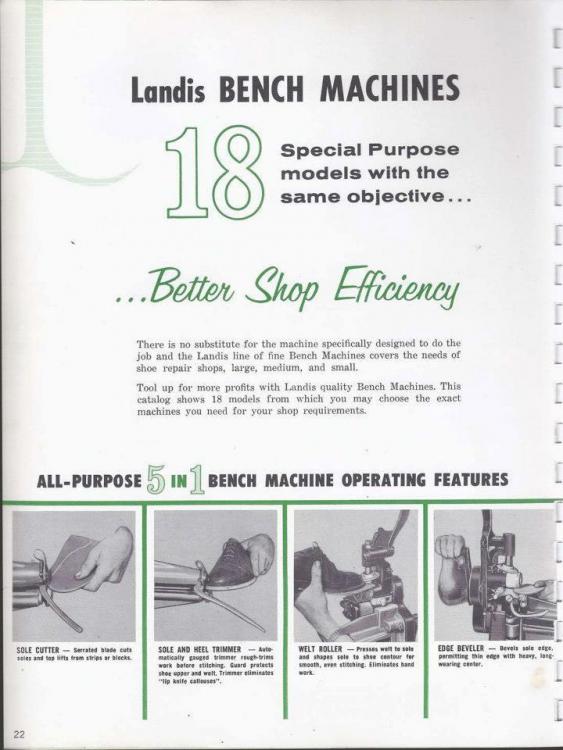

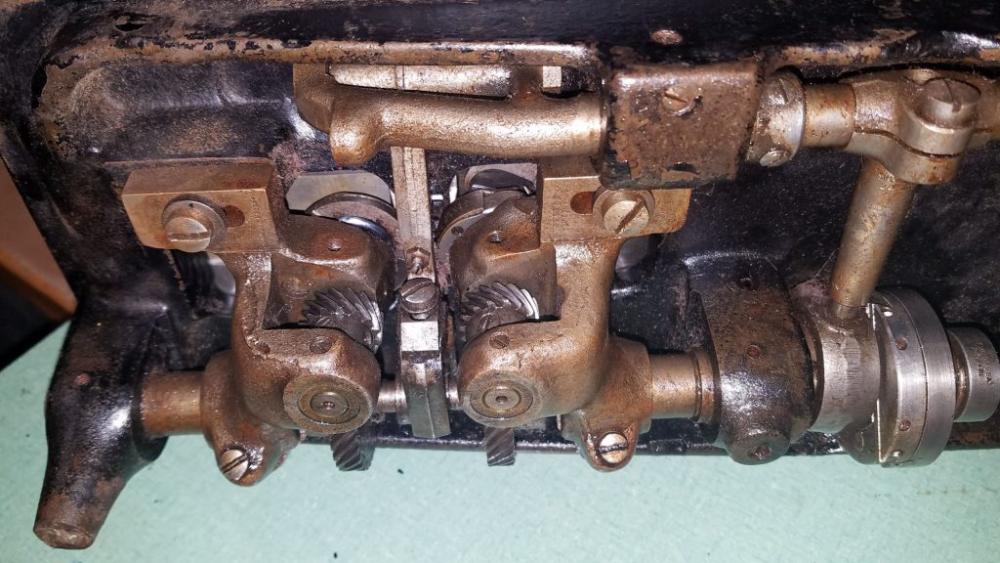

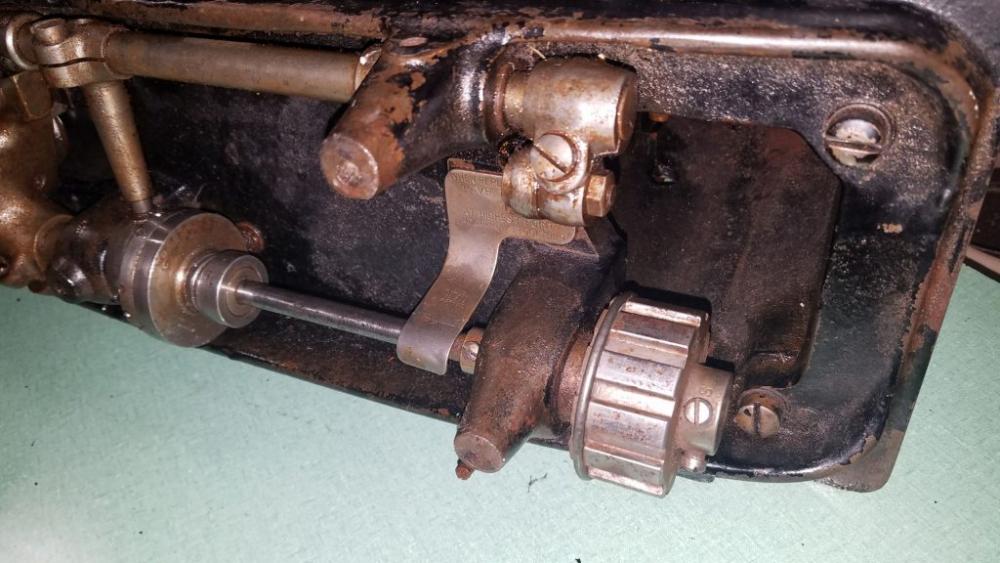

Acquired the following 4 pieces of equipment - right place, right time, good network of friends and informants............ Landis 5 in 1 Landis 3 in 1 Landis Model 30 (not sure) Splitter and the Champion Model 11 Splitter. Cannot seem to find much on the Model 11 - just mainly the Model 10. The picture shows it with the knife removed. Appears to be complete with no visible damage. I am seriously considering doing a tear down deep clean, etc. Anytime the words Champion and Splitter are in the same sentence all I seem to get are Log Splitters. Does anyone have any documentation hidden away somewhere?? My biggest concern, other than trial and error, is setting the knife properly after I get it sharpened. Not looking to do any painting...... It's got very nice patina. Will most likely be selling this one after I look more closely at the Landis 30. Also probably keep the Landis 3 in 1 and sell off the 5 in 1. Thank you for your time - truly appreciated. Stephen

-

This item has been sold.

-

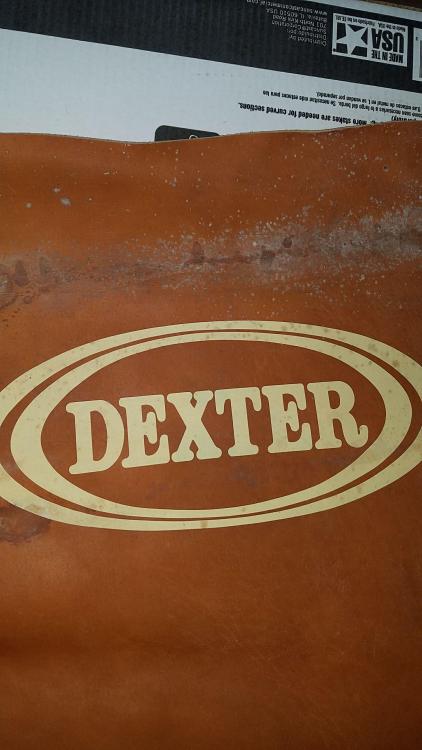

Greetings...................... I have no history on this piece. Was given to me by a co-worker that came from his parents estate. Google search comes back with nothing, nanda, zero.......... Would love to learn more about it. I would love to do my best to restore (rejuvenate) this piece and hang it in the shop. At first glance it appears to be mold (maybe). The leather is rather soft and supple. I am not going to attempt anything until the masses have had a chance to chime in. Thank you, Stephen

-

Looking for info on machine I recently purchased?

Smooooth replied to Rpatterson86's topic in Leather Sewing Machines

Looks very familiar. I have a 'Family' servo and a speed reducer. This is also somewhat new to me and still trying to figure out all the adjustment points. Stephen -

Consew 756R (Seiko CH-8B) - Going back to 794H Needles???

Smooooth replied to Smooooth's topic in Leather Sewing Machines

Thank you!!!!! Conversion today was successful. Only Issue I am working around now is Forward and Reverse stitch lengths using the stops. Had to slide the small bracket up on the stitch length selector to limit forward and balance it with reverse. No big deal. Did everything you mentioned and watched a Uwe video for a 441. Good time for an in-depth cleaning. Added the Speed Reduction today, big difference. Used some JB Weld to fill in the grooves on the Throat Plate and Feed Dog (extra set) to minimize markings, something I had been fighting with on some of the harness work. This machine came out of the LL Bean R&D Lab. Never used for production. All in all it has been a very good day. Thank you, Stephen -

Mechanics Question!!!! My Consew 756R (Seiko CH-8B) originally came from the factory set up to use 794H (DYx3) needles which are 69.0 to 69.3mm in length. The machine had been modified (adjusted) to use 328 (DDx2) needles which are 60.6 to 61.2mm in length. Unsure of the reasoning why. Trying very hard no to overthink this, I should be able to raise the needle bar to its proper height for the 794H and that should be it, other than a full timing verification. I am doing harness work and would really like to gain back that additional height. Other than the availability of certain needle point styles - What might I be missing? Thank you, Stephen

-

Would someone please be kind enough to move this to the correct category? Accidentally placed in it 'Sewing' - Thank you - Stephen

-

Landis Model 25, 5 in 1 Sole Cutter, Sole and Heel Trimmer, Welt Roller, Edge Beveler, Skiver Came from the estate of a small shoe repair shop owner. From what the family told me, he was the original purchaser. Took very good care of his equipment. I spent just a little bit of time doing some basic cleaning. New Spring - One of the bolts on top in the back is not original. All the photos can be seen here: Landis 25, 5 in 1 $750.00 will include shipping to the lower 48.

-

Thank you for the comments, and the Manual. I agree that it is not rust. The flash actually makes it look worse. The top and bottom movement is actually quite free. Starting to look for parts. Today I acquired a beautiful Brother LS2-B837 to play with. Once again, Thank you!!! Stephen

-

Greetings all............... First I want to thank everyone here. Every time I search for any information, a link to leatherworker.net pops up. So yes, I have been lurking for a while as I search for my first Industrial machine. Please understand that I know nothing!!! Just a dry sponge in search of knowledge. Hours upon hours of reading, and watching YouTube. I have pretty much narrowed my search down the the Brother LS2-B837, Consew 226, and the Singer 221G156. I am in no hurry and one of these will find me when the time is right. I started working with Marine Vinyl, creating a couple of motorcycle seats. That is just about the upper limit of my Singer 301. (PS - I have over 35 Vintage Singers in varying states of rejuvenation). Sooooooooo, how did I get here? Below are pictures of a 112WSV110 (Date Unknown) found in my neighbors shed. I have started the tear down and rebuild process. I have learned quite a bit, and yet still feel that I need to learn more. Motor aside (which is new), I would like to learn as much as possible regarding recommended updates / upgrades. While I am in that deep, let's just go for it. The biggie seems to be the Needle Bar Upgrade to a threaded unit. I am all ears........... P A R T S ? ? ? ? - This model really isn't listed anywhere, so finding the correct manuals, parts list, etc. has been fun. I am looking a supplier besides (in addition to) eBay!! My preference is to find a supplier where knowledge is abundant. I know I need to order a bunch of parts. I have been sewing with #92 Polyester using a 110/18 leather needle. So I now need to figure out what to order for this machine. Enjoy the pictures of my SV. I probably should start another thread somewhere regarding this journey, but for now........... Thank you, Stephen