Damas

Members-

Posts

105 -

Joined

-

Last visited

Profile Information

-

Location

France, Burgondy

-

Interests

Horse riding, photography, gardening and so many other things

LW Info

-

Leatherwork Specialty

I am a leatherworker

-

Interested in learning about

Design and make horse light tack (bridles, etc.)

-

How did you find leatherworker.net?

Googling

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Damas's Achievements

Member (2/4)

-

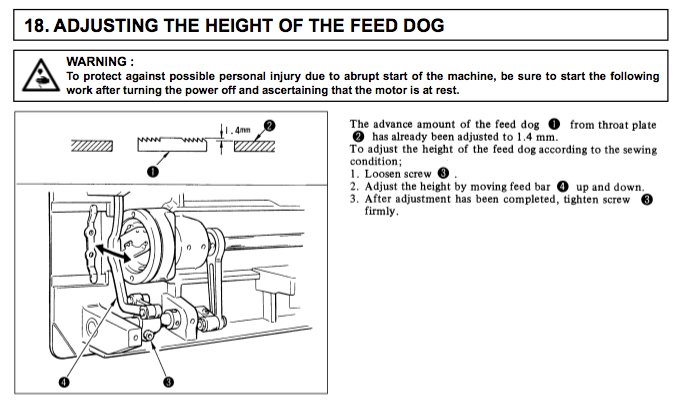

Just in case someone else is searching for a synchronised biding attachement for a 545 I found two more sources : AE : https://fr.aliexpress.com/item/1005004038229846.html? DIY made :

-

I'll try that too 👍

-

I believe not, according to user manual, but I can be wrong That makes sens. I intend to use 20 (tex 135) top and 30 (tex 90) bobbin, with a 120 needle. I suppose I'll have to get a new bobbin case for it... I'll give that a try !

-

Hello All, I recently had the opportunity to get a Pfaff 545 : And I am experiencing an issue with tension : There isn't any notch neither in bobbin case top, neither in bobbin case base as it normally should (circled in red below, sorry blurry pic). As a consequence, thread is pinched hard while sewing, and pulling the needle thread to the bottom of my work, no matter how I try to set upper tension or bobbin tension. Have any of you having this machine, a similar problem and how did you deal with it ?

-

My Pfaff 545 H2 also came with 134-35 needles, depiste the fact that is should use 134 needels according to Pfaff standards. It has probably been modified to run with with 134-35 needles at some point in it's previous life and I keep it this way

-

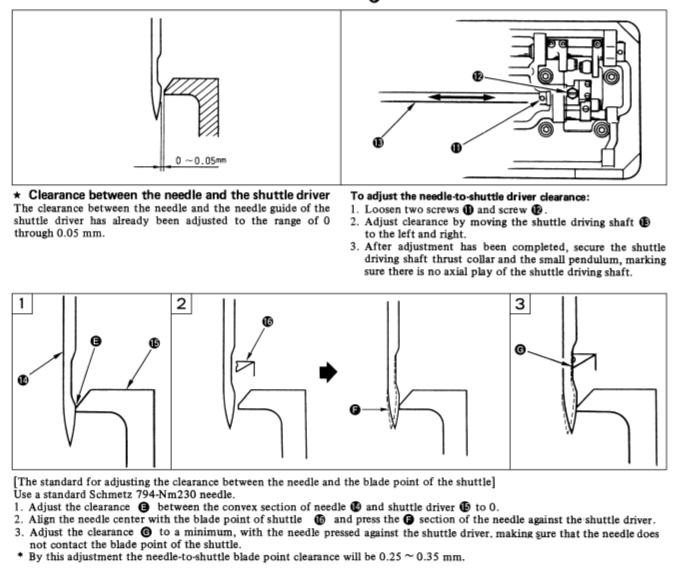

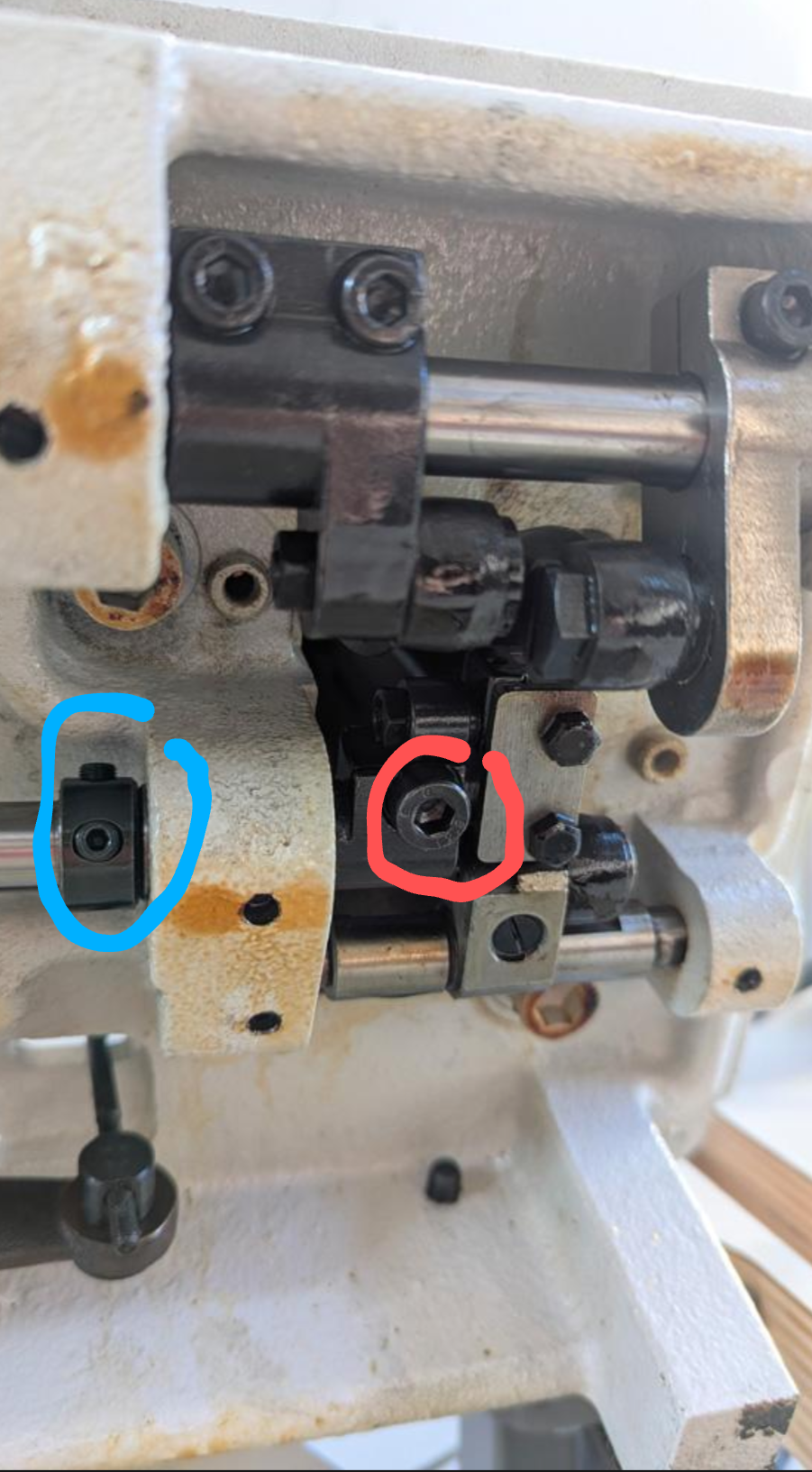

@AlZilla I tried this already, no lateral movement... @friquant yes, I used a brand new 230 needle as recommanded in engineer's manual and then my usual 160 to check every modification Thank you both of you for your kind words and help through this journey 😅 it helps ! I feel less alone 😆

-

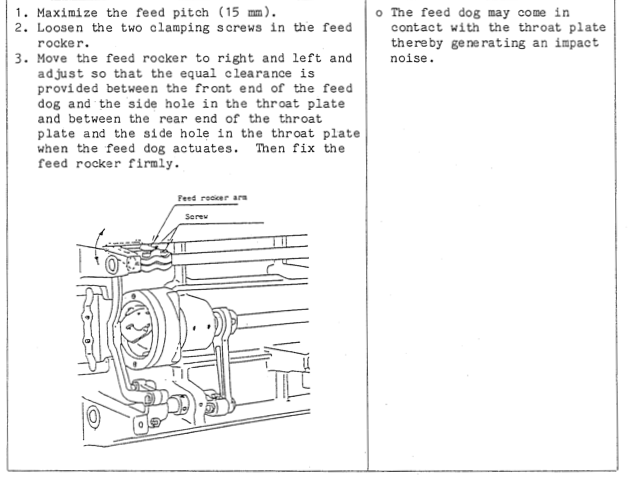

Yes, it is still all the way to the right, as it was in the begining. I messed up eveything trying to do what @Constabulary was suggesting. It's been the hard way to learn that these screws/settings will only allow me to move feed dog original position from : - Up or down - Back and forth The procedure I should now try is the one suggested by @friquant and it should allow me to move the needle bar block in order to center the needle. This is why I am reluctant. It's clearly the feed dog which should be moved but there is no way to do that. My last option is now to move the whole needle bar block

-

Thank you to all your advices, I finally succeeded to unfroze that screw. I tryed to move the shuttle race accordingly to manual but the shuttle itself was then rubbing on the other side of the race so I revert to initial position... to realized that I messed timing up and had to resync everything... I then decided to see if I could move the feeddog, and messed up everything again... It took me another hour to understand what to do and fix that issue So I am now back to the start point. I am considering doing the procedure below as suggested by @friquant but i am messing up so much that I feel a bit scared... My situation is number II so it won't be an easy fix procedure

-

Yes, allen wrench and nothing stronger than wd40 It's the red circle, the blue ones are ok. I am supposed to free all three in order to move the all shuttle part according to engineer's manual As shown here :

-

@AlZilla working on it 😅 @friquant I have the chapman set, it cost me much more here in Europe but it's so far one of my best buy, no regrets ! The screw is hexa type and above in size of the ones included in the set. I put some wd40 yesterday, I'll try again today...

-

Hi, well I guess I will have to make discussed adjustments first, and then post feedback here once done... So far my issue is a reluctant screw that I am still trying to free in order to proceed I also post extra pics as requested by @Constabulary and @AlZilla

-

There is the local album link

-

I'll do that today, sorry

-

To All, thank you so much for your help. I asked a manual from Hightex EU and they sent me the attached leaflet (CB7243 is the other name of CB243)... Also, I took pictures and made videos of my machine, I hope it will cover all the pics you asked for, but in case not, I will take some more ! In order to ease overview of the machine, I did an album : Here is the local album link 7243.pdf