327fed

-

Content Count

527 -

Joined

-

Last visited

Posts posted by 327fed

-

-

-

I saw a similar Kydex boot holster for a small auto. Thought I would try it out for a Bond Arms derringer. Second try, both have problems. Should be sturdy as it is glued, sewed and riveted. Finished with EVOO that I am not that impressed with. Also my first shell loops. Too far apart I am sure although I measured cartridge plus 2x leather thickness. Main problem is gun won’t extract when on boot. Extracts fine off boot. Carries well, comfortable. Wondering if it needs some kind of stiffener behind pouch.

-

I would say I want it if I knew how to PM.

-

Mostly I need some project time as I am working full time plus. Probably get one leather project out a month.

-

I need all the help I can get.

-

I’m just across the line in Tennessee.

-

I am putting up a building for my leather working stuff and some other rec items. It will be a pole building and have plank floor and metal roof and walls. No heat unless I am working in here. My leather is in the living room floor now. Thinking of using an upright metal cabinet to store leather rolls. All veg tanned. Could add a gun safe humidifier or light bulb for a little heat. Just want to avoid green leather mold,and mildew smell. Any ideas?

-

# 6 for sure spindle off the Head of a cotton picker. Twists and pulls cotton out of bolls. I use them as a stamp and punches.

-

-

I did the clutch lever extension. Helped quite a bit. I think the motor/clutch was new and is wearing in and working a bit smoother.

-

Thanks.

-

Found the original pulley on Amazon. 1/2 inch for this one and Singer 111.

-

8 minutes ago, Wizcrafts said:So, feather the damn clutch!

Yes, I do. And the belt slips. I can manage. But back to the original question, anybody know the shaft size on a Consew 225 pulley?

-

Yes it had a 2 1/2 or 3 inch pulley when I got it. Now has a 2 inch pulley. Really not that much too fast - just would be nice to run a bit slower. Hate to invest too much in the setup - no income from hobby, machine really is marginal for what I use it for. One of these days I will journey to Tractor Supply and get pulleys, make a jackshaft, etc. to slow it down. I think a pulley under 2 inch would not have enough area and slip more than it does now.

-

In-law is 3 hours away. Just wanted bigger pulley to slow it down a bit.

-

I guess you can have too much retention. Just made a Rhodesian style holster for 1911. Wet molded it and boned it all I could and set it in front of heater vent last night. This morning gun would not come out of holster. Ripped a couple of stitches and got it out. Added a rivet at top to patch my stitches. Good thing I don’t make my living with leather.

-

I have a Consew 225 that is in good shape with clutch motor. Got it through an in-law who services sewing machines and It works ok and will barely do my one use on holsters. He showed me how-where to lube it. When I do a holster it might sew 2 minutes, then sit in my shop for a month or 2. How often to oil it? Unlikely I will live long enough to put 8 hours on it.

Also, does anybody know the shaft size to upsize to a larger pulley on the machine?

-

Thanks. Very educational site.

-

That’s neat. Thanks.

-

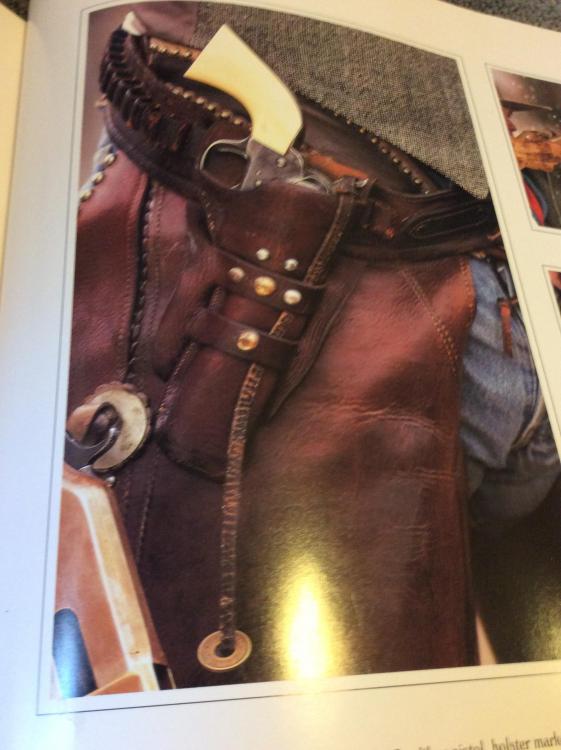

The way that thong is tied to the hammer it would be petty slow to deploy. Maybe when you fan it from the hip the tie down cones off.

-

Could have been added later as it is not attached. I would hang that strap in the hay baler if I wore it long.

-

Thanks. It was in “Cowboy Gear” by David. R. Stoecklein. My reenactor buddy loaned me some coffee table books from his collection for holster ideas. At least some of the stuff in the book looks authentic. This holster was marked “Moran Brothers. “ I usually just punch 2 holes in front of rear sight and put a thong loop.

-

-

Don’t think you can make it lighter and not soften the blow.

Trouble cutting leather

in Getting Started

Posted · Edited by 327fed · Report reply

I have found these hook utility blades really great, especially on curves. Hard to keep vertical and hard to find. I think these came from Lowe’s. I also use a wheel fabric cutter a lot on straights, but the steel ruler ruins them pretty quick. I also picked up a $6 led desk lamp at Walmart. Small, easy to move and pinpoint.