327fed

-

Content Count

527 -

Joined

-

Last visited

Posts posted by 327fed

-

-

Sorry I meant to say neatsfoot oil. I would not do linseed myself. Getting my gunstock finishes crossed with my leather finishes.

-

A coat of linseed and 1/2 a day in the sun will darken that just enough.

-

Nice looking pig. I helped some guys cook 304 butts Saturday. Then I cleaned out the pits and pressure washed grills Thursday. Ready to nap.

-

Try thread exchange.

-

I bought a pallet of stuff at a sharpening service many years ago. Before I quit bidding they threw a box of these circular knives on. I have maybe 30 . 6 3/4 inch diameter, very sharp, beveled one side. Wonder if this would make a head knife if cut in 2. Not sure how to mount handle. Maybe leav a stem at the bottom.

-

I am building a pole building for leather work and some other pastimes. Was thinking of using a tall metal cabinet for veg tanned. Wonder if it will mold (unseated)?

-

-

Thanks guys.

-

-

Depends on which table or mounting setup. Can measure with a rope to get an estimate, or use one of several online belt length estimators using pulley center to center and pulley dimensions. Keep receipt from auto parts store if you need to swap.

-

Nowadays it’s called Permatex Gasket Shellac. Dark brown, never comes off. It used to be in a glass bottle. I slammed it and broke it in the door of a 72 GMC. Never wore off the running board. It has a Chief’s head on the bottle. If you want it off you have to scrape it off or use a steel brush on an angle grinder.

https://www.amazon.com/Permatex-20539-Indian-Shellac-Compound/dp/B0008KLOG6

-

How bout some Indian Head gasket shellac or RTV gasket maker? Messy - have to use sparingly.

-

Have you considered a bigger house?

-

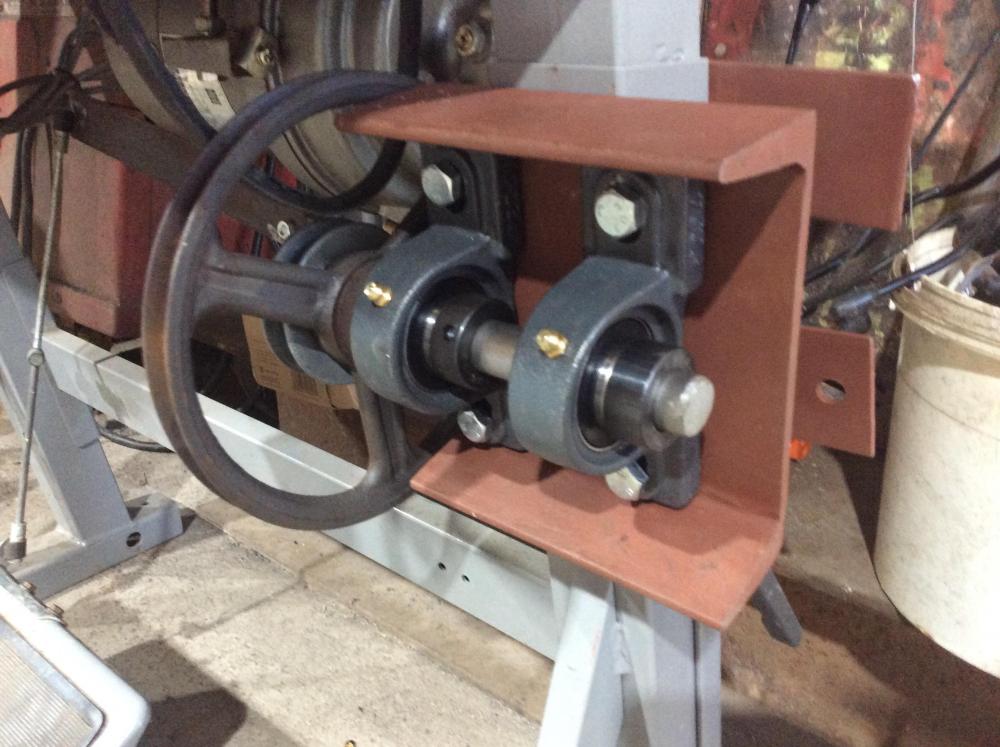

This machine for sale on leatherworker.net has a simple reducer but I am unsure what type of bearing is used.

-

A question on pulleys. The sewing machine belts seem to be 3/8 inch. Some companies call them L or M series. Auto zone has a 15 series. All the pulleys I have found for sale are A series (1/2) or A and B series ( 5/8 inch). I just had the narrow pulleys on hand, one came off my clutch motor. What pulley series matches 3/8 inch sewing machine belts?

-

Brings tears to my eyes.

-

These u bolts might make this simpler.

Could use a wood 2x6 on each side and longer bolts I guess if you lack a drill press or steel. I guess I’m a metal guy.

-

If one were starting from scratch, 1/2 inch bearings, shaft and pulleys would be plenty heavy. 1/4 x 6 flat bar on front and back, maybe 5 inch wide, would be cleaner. 4 inch bolts would leave room for lock nuts. Grey primer would match better than red oxide. And a sheet metal belt guard to save the knees would be a good idea. I just had all this Saturday and did not want to drive to town.I measured belts and used 2 online belt length estimators and still made 3 trips to Autozone to get a fit.

-

Yes. The bolts go on each side of the table leg and through the holes in the flat plates behind the post. Creates 2 clamps similar to a u bolt. No holes or attachment to post except the bolts pull tight. The extra hole was in the plate from its last life. Loosen bolts to slide reducer up and down. I will get a picture tonite maybe.

-

Thanks. Sure changed the personality of the machine.

-

I have a Consew 225 on a Pfaff table. I thought I could make a speed reducer that clamped to the square tubing table leg (many sewing tables have these). To adjust I could slide the reducer up and down. Doing this, the clutch motor does not have to be moved, the belt slot in the table does not have to be widened. I did have to move the bobbin winder back, move the motor pulley all the way right, and remove the belt shield on the motor. I had a 3/4 bore by 7 inch and 2.25 inch pulley, some 3/4 shaft, and some 6 inch channel. I would have preferred flat bar but had none. I oredered 2 $12.50 pillow blocks from Surplus Center, got 4. 3.5 x 3/8 bolts and nurs, and 2 pieces of 2 x 1/4 flat bar to clamp the reducer. Would have preferred square u bolts but could locate none. My cost with belts around $50 plus shipping. Can quickly change back to full speed if needed.

-

Constabulary was nice enough to post a utube for me in feb. on how to thread a Consew 225. I can’t seem to copy and paste the link but it is in the thread “maxing out Consew 225”. Might help.

-

So pretty.

-

Been trying this thing all weekend. Broke one needle this afternoon. Got it sewing perfect on scrap. Same double shoulder as the 2 holster projects. Sew the holster, it wads up under feed dog, birds nest under bottom of project. Pulled stitches out and re sewed 5 or six times. Related to changing speed or direction. Finished the 2 projects. Will have to do something not leather for a week or 2. One holster for me, one for brother. His will do. Mine looks bad. At least it is for concealment.

From Tippman to...electric?

in Leather Sewing Machines

Posted · Report reply

If you are using machine portable it might be quieter bolted down.