SewMuchToLearn

Members-

Posts

22 -

Joined

-

Last visited

Profile Information

-

Location

Rochester, NY

LW Info

-

Leatherwork Specialty

bags, purses, totes

-

Interested in learning about

machines, techniques

-

How did you find leatherworker.net?

google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

SewMuchToLearn's Achievements

Member (2/4)

-

@RibMtn did you end up going with the Ferdco? I've been researching bell skivers and read that having a separate drive for feed roll and knife is a good feature, so I'm interested to learn more.

-

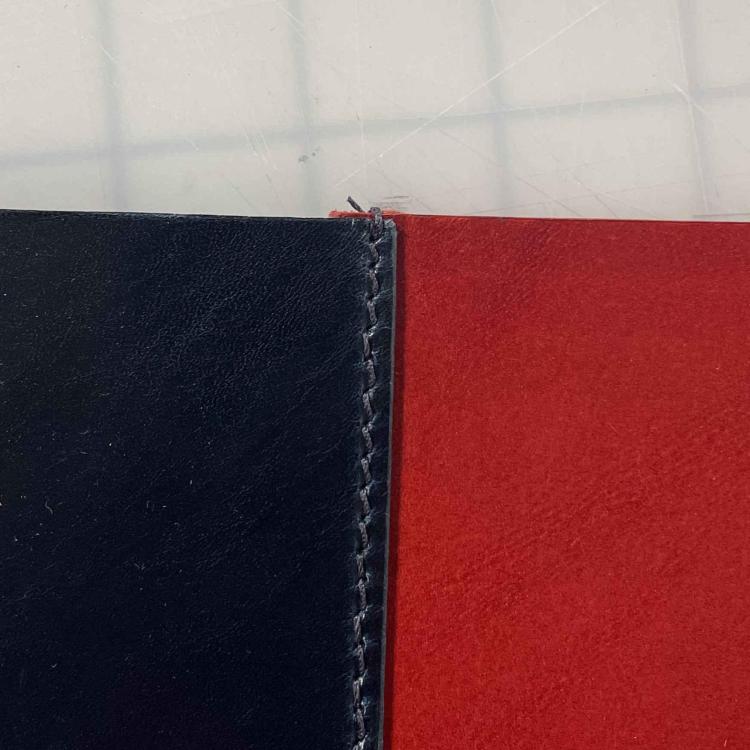

I'm working with 4-5oz veg tan to make bags and purses, and I'm machine sewing. I'm trying to figure out the "proper way" (most long lasting for durable bags, but also looks good) to finish the top of a seam in two instances: (And by finish the seam, I mean in terms of sewing, not in terms of burnishing/painting, etc.) 1) When sewing a gusset, for example at the top of the front panel on a bag: 2) When sewing an overlapped seam, for example, the top of a side seam on a tote bag: I've seen some videos where people leave long tails of thread on the seam and then hand stitch / tie off, though I'm not clear on exactly how to do that, or if it's the best option. My instinct in both instances is to start the seam a little bit below the top edge, backstitch 2-3 stitches as usual, and continue on, making sure that the thread doesn't wrap over the top edge (which it does in both of my example photos), because exposed thread at the top edge could get worn down and break over time. However, this means that the top millimeter or two of leather won't be stitched. Is that okay? I will be gluing the seam before stitching, so maybe that will be enough to hold it together. What do you think? How is this ideally done? My goal is a professional-looking and strong seam.

-

Tall post sewing machine in use

SewMuchToLearn replied to RockyAussie's topic in Leather Sewing Machines

This machine looks like a great addition to any workshop. I did a quick google search for "Cowboy 8365 tall post" and didn't find any info on it -- any idea who sells them in the USA and approximate price? Is this a new model? I found regular post bed machines, but not the tall ones. -

Juki LU-563 needle / presser foot alignment

SewMuchToLearn replied to SewMuchToLearn's topic in Leather Sewing Machines

Do you mean I should make it less tight? I cranked down on it in hopes of getting rid of the extra slop. If I loosen it, the center foot wobbles even more. -

Juki LU-563 needle / presser foot alignment

SewMuchToLearn posted a topic in Leather Sewing Machines

I am having trouble figuring out how to fine tune my Juki LU-563 walking foot machine. The needle isn’t centered (right to left) in the center presser foot hole, and the center foot isn’t centered with relation to the outer foot. Here is a link to a video of me hand turning the wheel — you can see some slop in the center foot — is this normal? Please share any suggestions of how I can dial this in better, or let me know if you think it already as it should be. I started looking at it more closely when it looked like my needle holes were excessively large for the needle/thread that I’m using. Photos show front and back side of a seam. (needle: 100/16 LR/RTW, thread: 69 bonded nylon, leather: veg tan two layers totaling 3mm or 7-8 oz). -

@Patrick1 I'm interested in your narrow needle plate and feed dog systems. My machine is a TechSew 5100, which I believe is comparable to the Cowboy 4500 / Cobra Class 4. I see at your website that you have two types -- Xtreme narrow and Standard narrow. 1) Can you help me understand when someone would use standard narrow vs xtreme narrow? My intuition is to go with the xtreme narrow, but is there any advantage to having more open space around the needle? I make bags and sometimes when I try to stitch close to the edge, the leather folds down into the open area around the needle, so that's why I'm looking at narrow needle plates in the first place. 2) I see that your needle plates that come with the feed dogs are flat, not rounded (aside from the holster plate which I'm not interested in right now) -- is the flat plate functionally different than a rounded plate? Can you help me understand why someone would use a flat plate vs the rounded plate? I see that you also make an xtreme narrow rounded plate, but it has to be used with the xtreme narrow feed dogs. What's the use case for that rounded plate? 3) What are pros/cons to stainless steel over black oxide finish (aside from price)? 4) What's the slot size in the xtreme narrow and standard narrow plates? Thank you for any info you can share! I'm posting here rather than emailing your directly in case others have similar questions.

-

TechSew 5100 -- metal piece sheared right off!

SewMuchToLearn replied to SewMuchToLearn's topic in Leather Sewing Machines

To close the loop on this -- I received the shuttle driver assembly from Techsew last week, as Ron mentioned above. Was able to get it installed and my machine working again. Techsew also offered me $150 credit towards a future purchase of replacement parts. As for this part breakage being caused by a thread jam -- I do not recall any such jam. Seems like if it was enough stress to break the shuttle driver, I would remember the jam. Regardless, I'm back up and running. Thanks all for your insight. -

TechSew 5100 -- metal piece sheared right off!

SewMuchToLearn replied to SewMuchToLearn's topic in Leather Sewing Machines

This is concerning to me, as I'm not mechanically inclined. TechSew is shipping me a shuttle driver shaft assembly. They sent me links to videos on how to replace it: Removing shuttle driver shaft assembly on the Techsew 5100 or 4100: https://youtu.be/sw63T_03mVA Installing shuttle driver shaft assembly on the Techsew 5100 and 4100: https://youtu.be/6GYa5apW7Sc They offered to have one of their technicians guide me over Facetime through it, so we will see how it goes. Not excited. -

TechSew 5100 -- metal piece sheared right off!

SewMuchToLearn replied to SewMuchToLearn's topic in Leather Sewing Machines

I am still waiting to hear from Techsew support on this. It is frustrating to have such a huge failure of the machine and no resolution from TechSew customer support. I've called and emailed them, and now I've lost another day of sewing time. I've heard such great things about TechSew support, but I have not experienced it yet. I'm hoping they can restore my faith in the brand! @Techsew Ron -

TechSew 5100 -- metal piece sheared right off!

SewMuchToLearn replied to SewMuchToLearn's topic in Leather Sewing Machines

Yes the needle survived. Yes, I will do that. -

I was just starting to sew on my TechSew 5100 this afternoon -- I had literally taken 2 stitches -- when a piece of metal flew out of the bobbin area. The piece had completely sheared off. Has anyone had this happen before? I bought the machine new from TechSew about 6 months ago and have used it lightly since then, probably only an hour or two a month, so I'm surprised. I assume it's a (major!) manufacturing defect in the machine. I emailed their support for help (they are closed for the weekend.) @Techsew Ron Has anyone had something like this happen? Any tips to avoid this in the future?

-

Designing a tote for strength and quality?

SewMuchToLearn replied to SewMuchToLearn's topic in Getting Started

@nstarleather What would you consider really good thread? I've been using Amann Strongbond Nylon Bonded thread (like this: https://www.wawak.com/thread/thread-by-material/nylon/?Brand=Amann ) -- is there a better choice? Is polyester preferred? I've heard mixed opinions. I figure that the cost of thread is miniscule compared to all the other inputs, so I'll gladly buy whatever is the best! -

Hi, I'm trying to take my bag-making to the next level in terms of strength and quality. I know that hand saddle stiching is probably the strongest way to sew a seam. But within the bounds of machine-stitched: what's the best way to sew a seam on a tote bag to make it strong? (like a side, bottom, or corner seam)? Wrong sides together and then flip the bag right side out? (first photo) Right sides together so the seam is on the outside? (second photo) Flat felled seam? (third photo) Something else? Where would you reinforce the seam and how (more stitching, rivets, something else?) I know that different seams will change the look/design of the bag. I'm starting from scratch here and trying to design for quality and longevity. I don't expect my bags will hold anything unreasonably heavy (shouldn't be filled with bricks, but maybe a few hardcover books), but want to know how to make it last. While we're talking quality -- what about straps? How would you attach those? Stitched or riveted or both? Will single layer straps hold over time, or do they need to be double layer? Thanks for your insight!

-

I'm in search of a Juki 441 clone machine (cylinder arm, triple feed, can sew up to about 7/8" thickness). I'm in upstate NY, so it needs to be reasonably close by, or able to be shipped (they are heavy, I know!) If you're within a few hours of Rochester, NY, Buffalo, NY, or Boston, MA, I'm interested. I'm not tied to any brand, but some models that would work are: Techsew 4100, Techsew 5100, Cobra Class 3, Cobra Class 4, Cowboy 3500, Cowboy 4500, and I'm sure there are many more. Searching for used because I'm just starting out and need to keep costs low...I'd be grateful for any leads! Thank you!

-

Hi, I'm interested! Where are you located? Is this for local pickup only?