jrdunn

-

Posts

392 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by jrdunn

-

-

Price?

-

Beautiful work!

-

-

3 hours ago, Frodo said:

Lol. I am not going to say snytjing

but you left this wide open for a bunch of yuk yuks

I kinda thought the same thing.

-

I do love the old Singer patchers. Good luck!

-

On 7/8/2023 at 12:19 PM, billybopp said:

The Osborne dividers are expensive, but they are by far the nicest I've ever used!

- Bill

My experience too.

-

1 hour ago, chuck123wapati said:

lol you would be surprised, every morning i go to Walmart the lot is about half full of $300,000.00 motor homes, they camp there for free, use the shitters in the morning so they don't stink up their rides then buy their food and drive on to the next one. Some rich folks are just as cheap as the rest of us.

Where is that "like" button?

-

7 hours ago, chuck123wapati said:

these are really cool there are many things you could use them for

Sundial?

-

5 hours ago, Klara said:

The thing is, if you are starting a business, you will also need to think about nasty things like taxes, insurance, overhead, advertising... I strongly suggest to keep leatherwork as a hobby for as long as possible.

These are definitely concerns. For me, I also have a "mind set" problem. It seems to change from "I get to do leather work" to "I have to do leather work". Another might be deadlines. As far as machines go, I'm no expert but I'm not sure you would gain much machine stitching knife sheaths over hand stitching. I do have a couple machines and enjoy using them though. As always, JM2C. Jim

-

Very nice!

-

I'm not sure this will help you much "down under" but here is a link to a place to buy one in the U.S. Jim

-

Very nice holster indeed!

-

Very nice holster!

-

Those are beautiful Bruce! Thanks for sharing.

-

Here is wishin' you the best my friend. I'd sing at your funeral but that would clear the house mighty quick.

-

Nice knife and sheath, Dave!

-

13 hours ago, Klara said:

I believe it's the construction out of one leather strap that's wider than the watch where it sits on top, with the two tabs for attaching the watch, that makes it aviator style. Has the advantage that the watch won't fall off if one of the spring bars comes loose. Like today's NATO straps...

Thanks Klara. I had no idea.

-

Nice work. For the less informed of us(maybe just me), what makes that an "aviator style"?

Jim

-

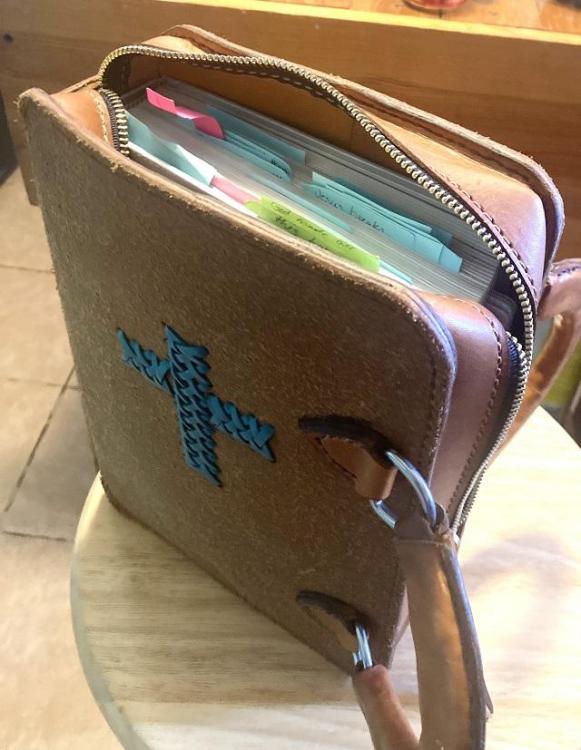

I used Making Leather Cases #2 to make one for my granddaughter. I nearly lost my mind(I never had a very tight grip on it anyway.). I truly wish you the best. I needed a slightly longer gusset than the book said but her Bible was 2.5" thick. I ended up making the whole thing twice. However, I am certain that you will do better than me! Here is a picture she sent me of it fully loaded.

-

On 4/21/2023 at 2:05 PM, Rwest said:

Same here..

I don't know where you are in Oklahoma but the Norman Public Library has a CO2 laser you can use for free if you have a library card. My son uses it to engrave some wood and leather things. I have been considering trying my hand at but don't know what I would have to do to get a card since I don't live in or near Norman. I think other library systems may have them but know that my local doesn't. JM2C. Jim

-

After watching more of the video, I'm leaning more toward a coated fabric.

-

I don't know. I thought maybe that was a RFID shield. Just a wild guess. Or maybe a poly strip?

-

Yeah, that leather don't look right to me. If you'll permit me just one more plea. . . I know that the fabric ones are more practical but a quality set of leather bags is just so . . . right!

As always, JM2C. Jim

-

8 hours ago, chuck123wapati said:

and i also apologize I reread and admit i sounded really rude, crude, i really was just trying to add to the conversation.

No problem here. I really wasn't clear.

Veg Tanned Satchel Bag

in Show Off!!

Posted

@ArkieNewbie,

Did you have trouble turning the body of the bag after sewing it? I don't usually make turn bags and have never made one of Veg Tan. I have a friend that made a "possible bag" from Veg Tan and has had fits trying to turn it. Just checking to see if you have some advice. Thanks, Jim