Rogueshoemaking

Members-

Posts

13 -

Joined

-

Last visited

About Rogueshoemaking

- Birthday November 1

Contact Methods

-

Website URL

sandalshoemaker.com

Profile Information

-

Location

Brisbane, Queensland, Australia

-

Interests

Leather work, Shoe Making, Leather Sewing Machines, Leather Tools,

LW Info

-

Leatherwork Specialty

Shoemaking, Sandal making, Watch Strap Making

-

Interested in learning about

Everything to do with leather, and how to do it.

-

How did you find leatherworker.net?

Searching on Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Rogueshoemaking's Achievements

Member (2/4)

-

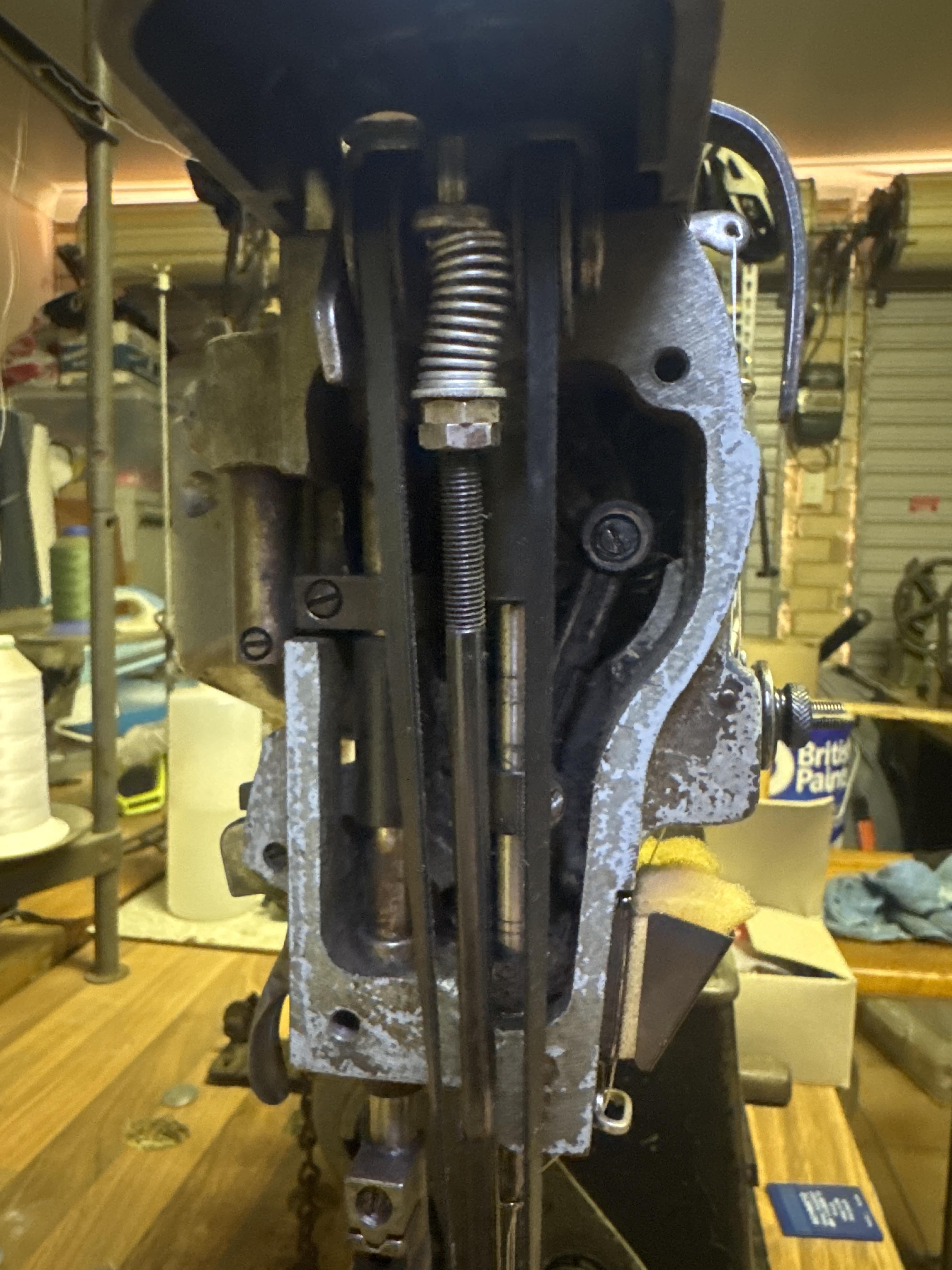

I believe I fixed the problem, why the needle wasn’t picking up the tread on the bobin. I must have upset the whole timing, when i loosened two screws under the shaft of the shuttle hook, and loosened two extra screws I shouldn’t have touched. when i was moving the horizontal cog to turn the shuttle hook shaft. I also moved another part bolted to the shaft that sits against the horizontal cog, the horizontal cog turns a vertical cog at the bottom of the shaft of the shuttle hook and when I moved the horizontal cog a little bit to one side I accidentally speed up how fast the hook turns round. and after a few hundred stitches it would skip a few stitches and then wouldn’t pick up the tread from the bobbin. didn’t take me long to sort it out, luckily. I have my 236g131 working again. a fantastic lesson learned, from a great mistake. I will add photos later on this evening.

-

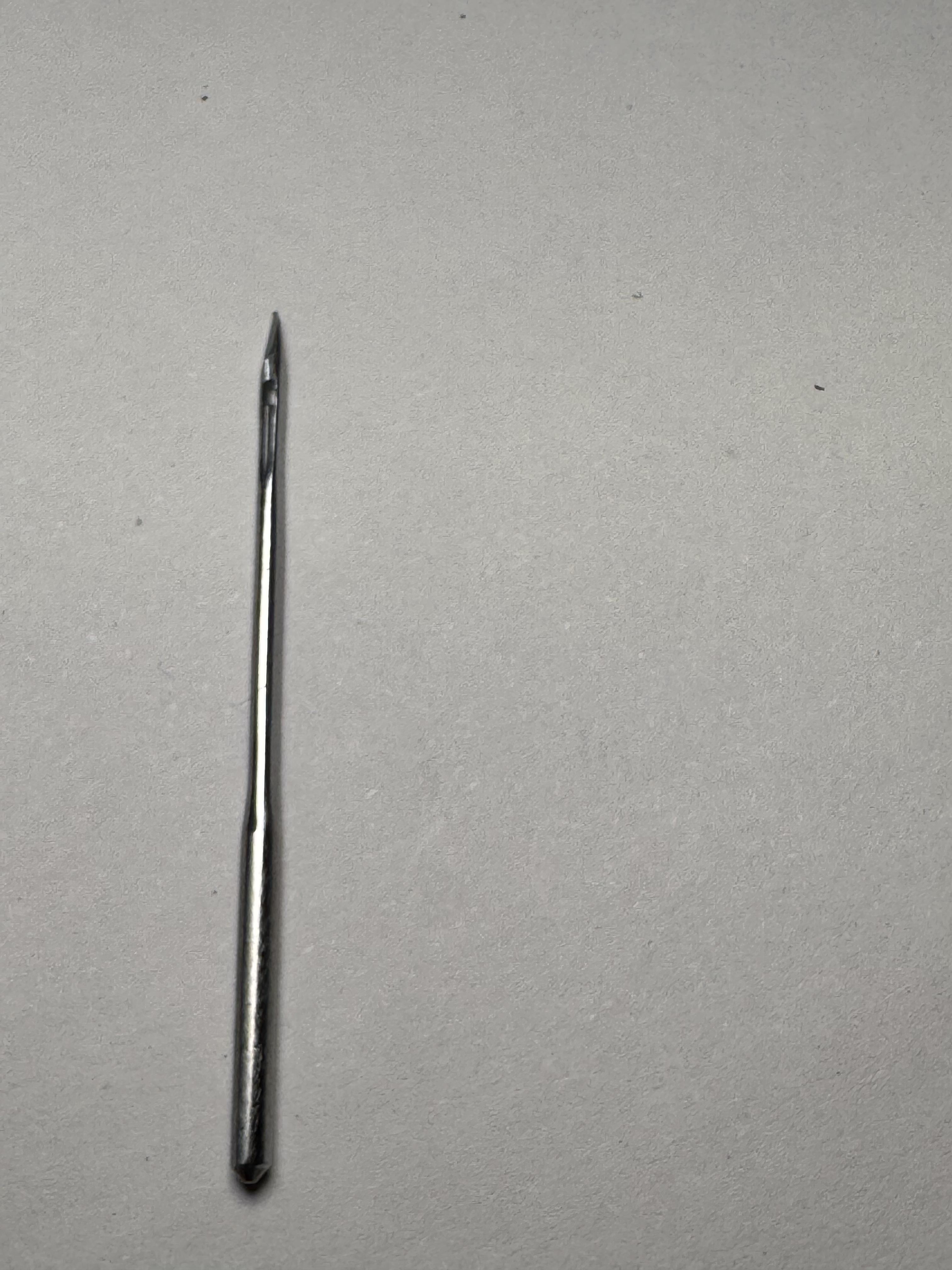

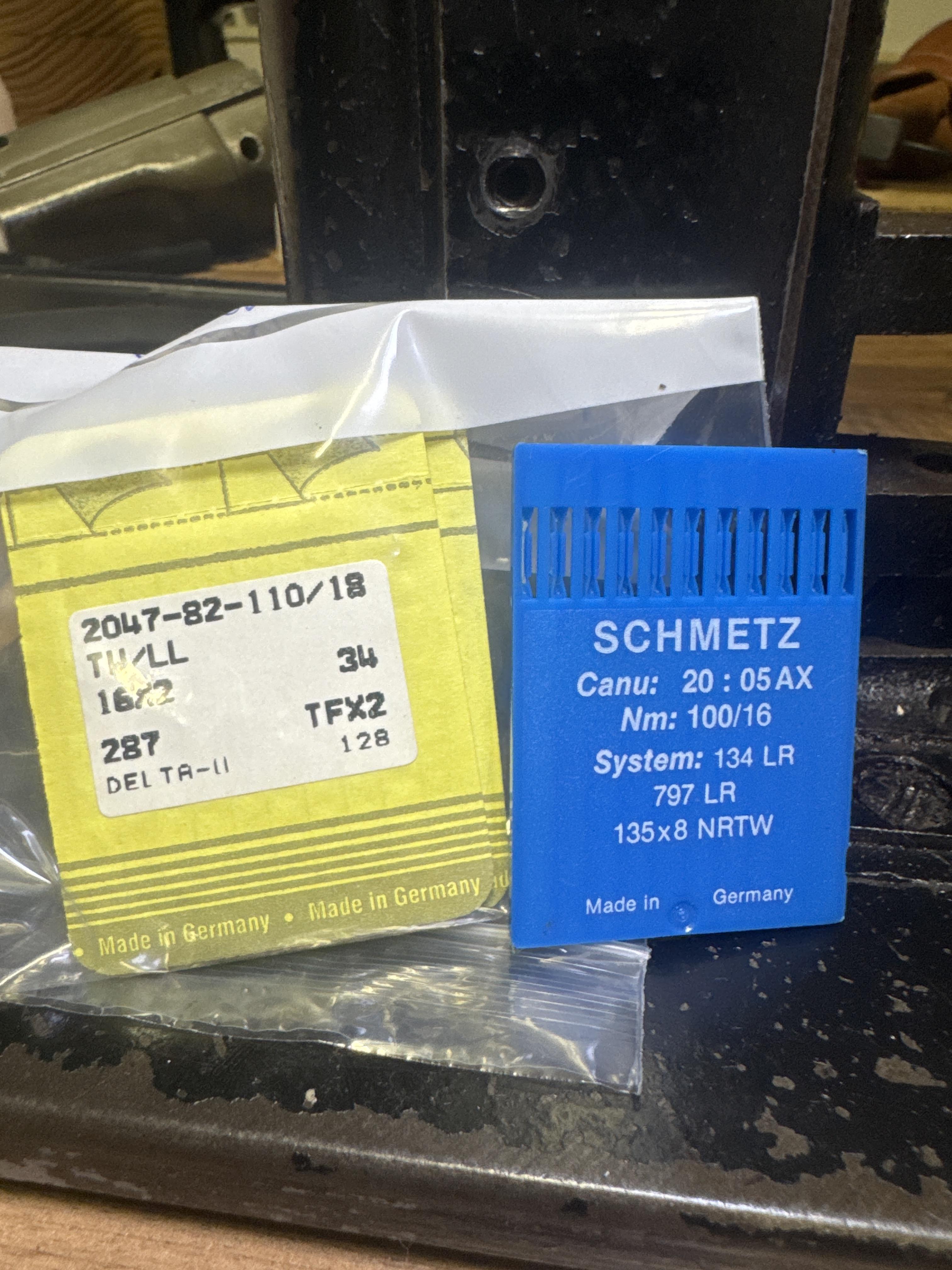

Hello RockyAussie, im was sure I had changed the 287 needle out to the 134 before I took that picture. You are correct RockyAussie, the 287 doesn’t have a scarf, or very much of a scarf at all. so that was the 287 needle in the machine before I changed it first two pictures are the 287(16x2) and the last few pictures are both the 287:right and 134:left the shaft off the 134 is very much wider in diameter.

-

Thanks AlZilla, they are indeed needle bar height and where the hook meets the needle. I’ve had it since 2021, but only noticed the marks this week after many attempts to set the timing. The 287 needles are far too thin, and the same length as the 134 needles. I have it picking up the tread from the bobbin with the 134 LR needles, don’t know what I did to make it work, since I was stopping and starting during dinner time. but it’s still missing stitches. So I’m still playing around with it. the 287 needles might not go to waste, I was told they would fit my Singer 331K16, so that’s great. thanks for everyone’s help so far, it can be a little bit frustrating, but I think I’m still enjoying myself.

-

Where would I find an engineers report to set the needle bar height to its correct position, I know the hook has to sit 1/8 above the eye of the needle, so 3.38mm. But does it change things if the needle bar is out of whack, can I just move it down to the correct height, below the hook, and everything else should work accordingly. I have the 134 LR needle back in. it can’t be the tension, and I’m running out of time to get this project done.

-

Hello Kgg. So now there is two different needle systems. so if AlZillas manual says it’s 287 (16x21) System, from the manual that states 236G131 which is the correct model I have. And the US model uses 134 (DPx5) is there any other way of finding out the correct system, other than the manual. I purchased the 287 (16x2) needles from Queensland Sewing Machines PTY, they were very helpful. And their technician told me that the 287 needles are much thinner than the 134 and if my nail bar was designed to hold the 134134 would fit inside and if it wasn’t a 134 wouldn’t fit inside and I would have to use a 287 so I purchased the 287 to give them a go on cross reference needles that I purchased from them before for the singer 236G131 and the needles I have seem to be correct. I now believe I’ve messed up the timing on the needle bar, where the elbow that turns the bar is not set right. And maybe have to turn the bobbin case hook to suit.

-

My name is Plunkett Based outside Brisbane, Queensland, Australia. I have a Singer 236G131 post bed used all my needles including the last one. I know big mistake unfortunately, and ordered more, the previous needles where Schmitz, and the new needles are Groz-Beckert. For the love of me, I’ve spent the last two days trying to fix something that probably wasn’t broke, but I thought the timing wasn’t right, because I was sewing nearly medium leather last with it, and it was fairly soft Chrome Excel. But due to it not working, I adjusted the needle bar, then I adjusted the bobbin case to make it closer to the needle, by loosening two screws from underneath. Still can’t get this needle to pick up the tread from the boobin, using the servo. It will pick it up when I do it by hand, the first time, and it will continue for five or six stitches , then I press the foot peddle, and no luck, just punches holes. I don’t know anything about needles, and wouldn’t know where to cross reference if they are the same. But somethings not right, and it might be the needles. ( gut feeling : no evidence ) I have attached pictures of the needles. Can anyone give me any advice, or help point me in any way.

-

ESTO brand Leather & Plasitic trimmer

Rogueshoemaking replied to LomaeArts's topic in Leather Machinery

Hello LomaeArts. would you be interested in selling me a spare cutting disc. I have a Pedersen skiver and rough edger. ive been looking for a blade for that a long time, and when I searched on Google, your post came up. and I can’t seem to load a picture of it, -

Thanks Constabulary, and James. turns out I didn’t need a motor or a control box. The motor is for the lining trimmer. I just needed two belts. the same mechanism that drives the bottom belt, also drives the top belt. Both the top feed roller and bottom feed roller have to turn at the same speed. So it makes sense. So I’ve ordered two new belts. The lining trimmer does look a bit bulky, but the previous owner has removed what he can, and I knew about the small stitch length before I purchased it. I really like the small stitch on a shoe, and I’m looking forward to experimenting with it, hopefully I don’t change my mind and sell it. thanks again…

-

Hello everyone, I have a Singer 236g131 and I am trying to get parts for it, but it seems impossible for this make of specialised model. I need a motor that’s built into the side of the frame, and a control box. the correct serial number for the motor is 713604-002 and the control box serial number is 995536-002 it has a round wheel bottom feed, and a round wheel top feed. I need the motor and control box to feed the top feed. It works ok at the minute, with just the bottom feed, however when you double layer your leather for shoe uppers, it’s slacking on the top stitch. I believe if the top feed wheel was working correctly. The feed would correct the tightness on the stitching on the top. Can anyone help with finding the correct motor and control box.

-

Thank you very much. just purchased a 236g131 and this has been very helpful. I just purchased the head. Is there a particular motor works well with this head. The motor I have is fast and very fast. thanks

- 1 reply

-

- singer 236w

- singer 236g

-

(and 1 more)

Tagged with:

-

I’ve just purchased one of these, I was wondering if you found out any information on it. Or may have found a manual. Thanks