sojourner999

-

Content Count

42 -

Joined

-

Last visited

Posts posted by sojourner999

-

-

Then a couple more punches and it was out. Easy, peasy, lemon squeezy. I guess I have one of the machines where it is easy to remove.

I needed a 3/32" roll pin punch (1/16" too small and 1/8" too big). Your mileage may vary. I have no idea how every pinned machine gets pinned.

I bought it from Amazon.

https://www.amazon.com/dp/B00QV2JTXK?ref=ppx_yo2ov_dt_b_product_details&th=1

tagging @Jhunter13

-

-

I was able to remove the pin that keeps me from adjusting the fwd/reverse stitch length balance on my Juki LU-563.

First i pushed a thread through the pin to ensure the pin went all the way through.

Firt

Firt

-

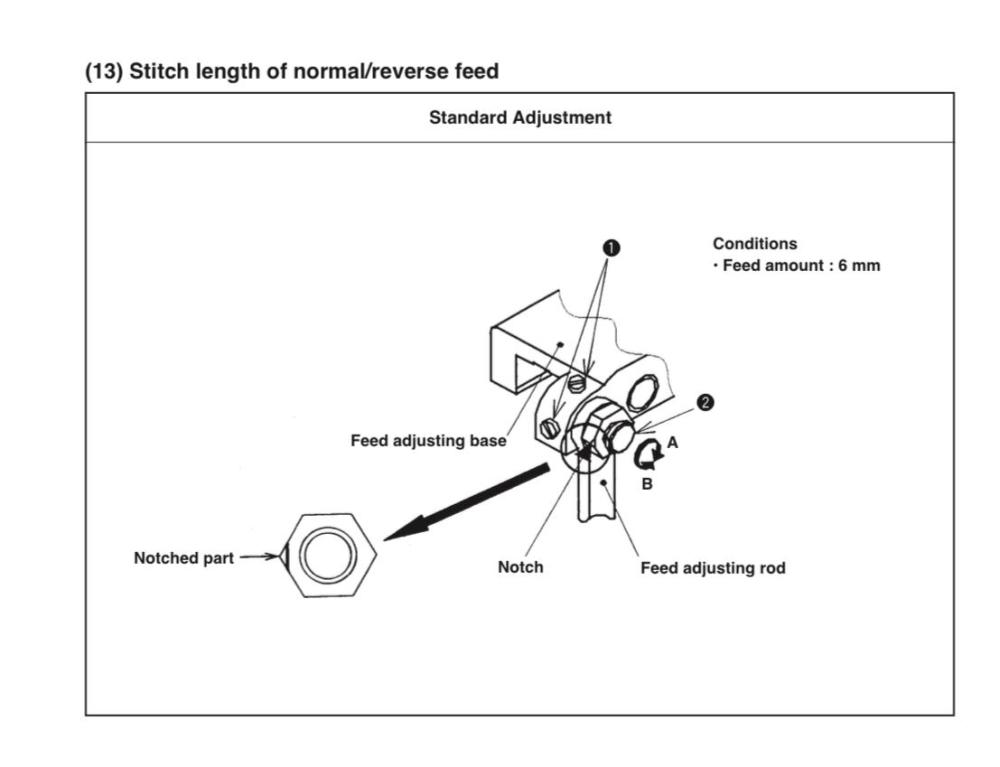

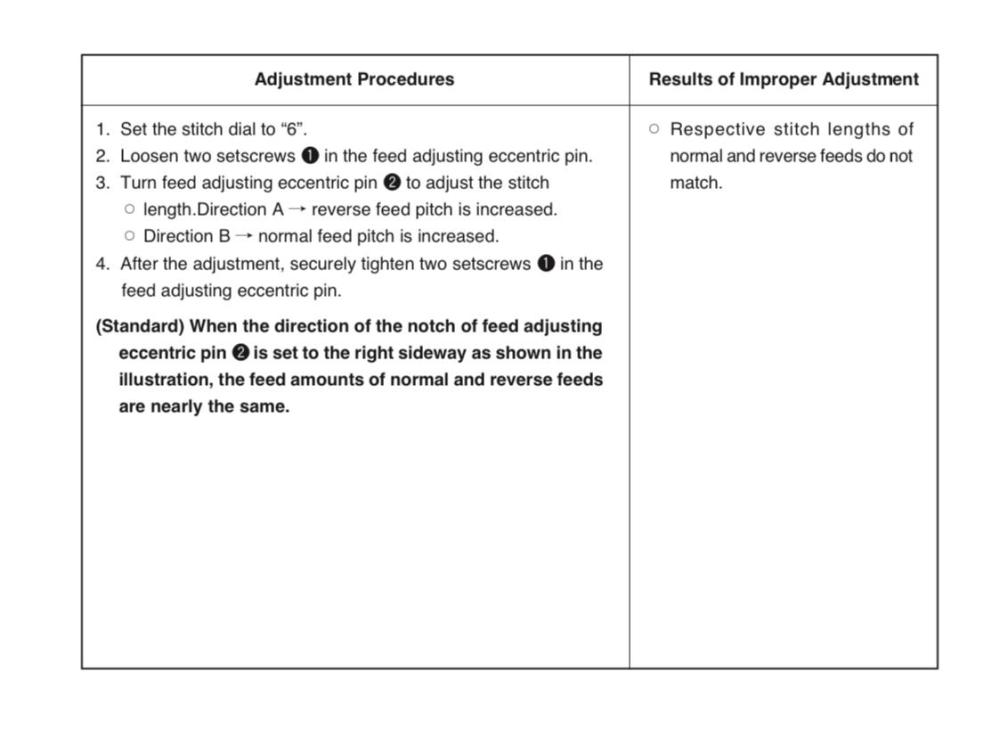

The instructions @1hp provided for consew 206rb-5 are exactly the same as the Seiko sth-8bld-3. They appear to be same exact machines with the former made in China and the latter made in Japan.

Looking at the Juki adjustment, i am not sure the Juki “pin” would be as accurate as a screw. And the Seiko/consew looks like the regulator rod would be similar in accuracy. That is just from looking at the images. I am thinking six of one and half-dozen of the other.

the Adler 867 looks real nice, but way above my budget at this time (hobbyist looking to eventually move to part time creator).

I am going to do some more research and see what I can find. Also, anyone else here with experience may reply in a couple days. Weekend and all.

Thanks!

-

-

Thank you @Uwe. I am going to look at the service manuals for the models I am considering. Sometimes I get “wrapped around the axle” trying to get precision that may or may not be there. I’ll look at the Adler, but that may be out of my price range. Much appreciated.

@1hp thanks for the share. Unfortunately, RB4 and prior do not have the parts that R/5 does when it comes to this adjustment. I read a post on here about someone who had success on an RB3 and that did not work for me. I also sent Seiko Japan an email and they responded with an adjustment for a different part. That part does not exist on my RB4. I believe I have exhausted all avenues for this RB4.

I am off to find some manuals and do some more research.

all - if anyone has real world experience with the models I mentioned, please share.

thanks!

-

Hi everyone,

I have an older consew 206RB4 where the fwd stitch length does not match the rev stitch length. Furthermore, with this model, there is no ability to match fwd and rev. I also acquired a Juki LU-563, where the adjustment for matching stitch length cannot be done because the part is pinned (

)

I mainly sew textiles, but want to get into leather (deer and maybe elk leather) for pouches or shirts. And I want to have a machine where the fed and rev stitch lengths are consistent at any stitch length.

I am looking at purchasing new, either a Seiko sth-8bld-3, Juki 1541s or Juki 1508ns.which of these machines would be the most “accurate” matching fwd and rev stitches at any stitch length setting?

Much appreciated for any and all input.

-

6 hours ago, kgg said:I would buy presser feet and a feed dog to fill with JB weld. First I would suggest two things:

i) if the feed dog is leaving unwanted marks check the height the feed dog is above the needle plate. It maybe to high and need adjustment.

ii) if the presser foot is causing the unwanted marks try reducing the presser foot tension.

kgg

Thanks for the clarification.

-

Thx. Just to confirm, you would fill the teeth on the feed dogs and buy a smooth presser foot from ali express. Is that correct? If so, I will have to research filling feed dogs with JRB weld to make smooth feed dog.

thx

-

thx. sailrite has three smooth feet set.

the one i posted earlier, for fabricator and 111 machines

one for ultra feed ls

https://www.sailrite.com/Smooth-Foot-Set-for-Sailrite-Ultrafeed-LS-1-Leatherwork-Sewing-Machine?gclid=EAIaIQobChMIw5_PwYqIggMV80lHAR15QQRuEAQYAiABEgKIZ_D_BwE

and one for ultra feed lsz

https://www.sailrite.com/Smooth-Foot-Set-for-Sailrite-Ultrafeed-LSZ-Sewing-Machine?gclid=EAIaIQobChMIw5_PwYqIggMV80lHAR15QQRuEAQYASABEgLH1fD_BwE

is it possible that you were referencing one of the other feet/feed dog set?

thanks!

-

Hi,

I have a consew 206RB-4 and a Juki LU-563. Both have servos and speed reducers. I have yet to enter into fabricating with leather. At this time I have no aspirations to sew very thick leather that would require a more powerful machine. I am looking at using some light weight deer leather to make some small items.

I ran across the sailrite smooth leather foot set (link below) and and trying to find out if the foot and feed dog are compatible with either of my machines. Does anyone know if this product is compatible with either of my machines OR if there are any other vendor provided smooth feet and smooth feed dog?i tend to be a gear junkie and would rather purchase smooth feet and feed dog rather than grind and fill standard feed dog and feet. That said, I will grind and fill if it comes to that.

I have an email inquiry out to sailrite, but thought someone here may have had experience with this.

any help, experience or ancedotes are much appreciated.

Thanks!

-

1 hour ago, CowboyBob said:Looks to me like you need to loosen the 2-screws that hold the stitch length cam to the shaft & only turn them 1/4 turn(because one of them goes into a slot on the shaft) & then tap on it to slide it to the left so it lines up.

Thank you. I am going to look into that. I am reading the manuals now.

-

1 hour ago, Quade said:I have the stitch length button out on my Singer. It's just a button with a spring and a C clip to hold it in place. When you press it down, it engages with a disk on the shaft. It holds the disk in place. When you turn the hand wheel, the shaft turns, this changes the "gear ratio" by lengthening and shortening the stroke of an arm.

I'd flip her over, then look at the center shaft which is either belt driven or gear driven. Press the button down, turn the hand wheel forward and see if the center shaft turns. You should see the eccentric mechanism and arm and you should see the disk which has a cut-out the button is supposed to engage. I'd see if the button seems aligned with the cut-out. You can hold the disk in place with a screwdriver or pliers and try turning the hand wheel to make sure it actually adjusts and isn't stuck.

You can see it on page 3 of the parts manual posted above.

Thank you. @Jhunter13 walked me through this when I was at the sellers property. It is belt drive. I can see the cutout. I line it up with the disk, but it doesn’t appear to catch. I tried holding a screw driver on the disk and was able to turn the hand wheel, so it appears it is not stuck. I just can’t get the stitch length button to catch the indent. Looking at it, from a weird angle, it appears to not be centered in the cutout. Maybe it could also be the button was ground down from improper use?

How would you remove and re-install the stitch length button? And if it is not the button being too short, can you recommend how I would adjust the “left/right” of the disk so the button is in line with it?

much appreciated,

-

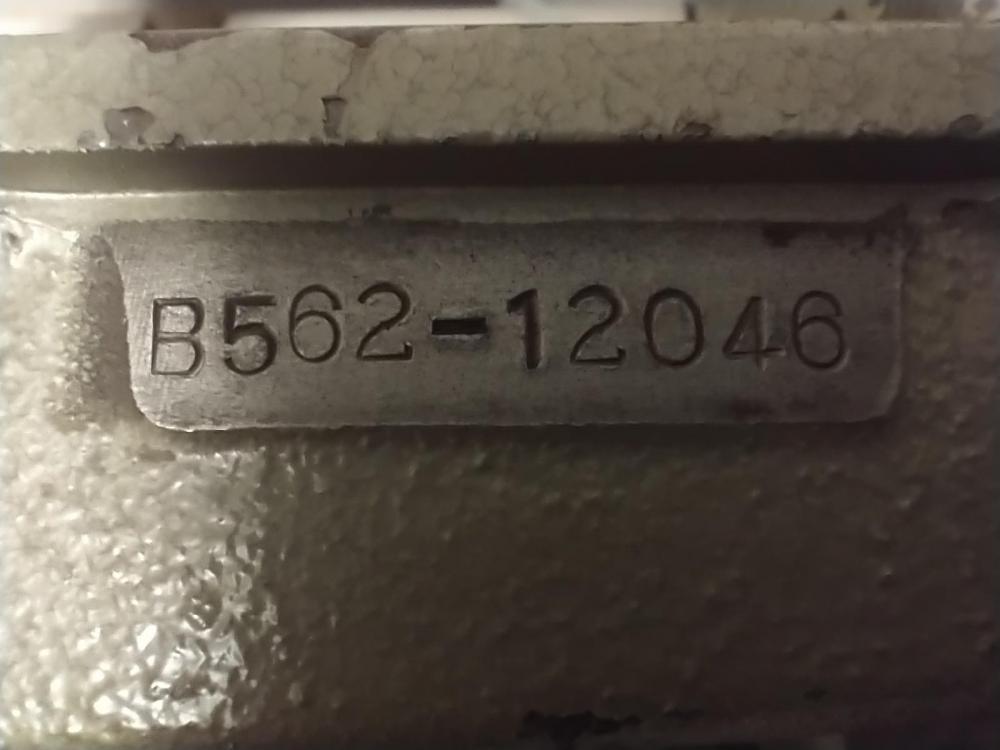

2 hours ago, SARK9 said:I've had/have several "real" Juki LU-563s and an older Chandler badged "CU-563" which as far as I could tell, was identical to the Juki machines. I also have a Chandler badged 562 which is printed "Made in Japan" under the badge, rather than stamped ON the badge, as is seen on my Jukis. The quality of these older chandler marked machines was on par with my genuine Juki products as far as I could tell. The Chandler "562" shows 200R on the badge, and could possibly be a rebadged Consew 226R for all I know, rather than a Juki, except I don't see SEIKO cast on the underside of the bed as I think was done on most of the early Consew contract machines. The Chandler badge might ding the resale a bit, and that was the only downside I saw, as they are fine users, and the 563 actually had the BA0 hook assembly installed, though who knows if it was original to the build. I never felt handicapped in the slightest with any of them. -DC

Thanks for the info. I didn’t see anything stamped that would make me think it was an original Juki. But as long as it is Juki level quality, I should be good.

-

16 minutes ago, shoepatcher said:Looks like a rebadged early Juki.

glenn

Thanks.

Are you familiar with any differences with rebadged (assumed Juki produced and chandler put it’s name on the machine) versus clone (where I assume it was made in China to same specs as the original Juki)?

-

3 minutes ago, CowboyBob said:Here's a parts & operators manual for the Juki 563 & all the parts should interchange.

Juki_LU_562_563_Manual.pdf 7.15 MB · 0 downloads Juki_LU-562,_-563-1.pdf 12.82 MB · 0 downloads

Thanks! PDFs downloaded.

-

Hello again,

Thanks for all the help on the Consew 206-RB4 I acquired previously. Since then, I have added a speed reducer and am very pleased with that machine. That said, I ran across a deal on a Juki LU-563 clone or re-badge. A Chandler Chandsew / CU563. It sewed fwd and reverse. There is a minor hiccup with the button for stitch length selection. It might need replaced or just some oiling. It won't catch in the detent to allow changing stitch length. And it is missing the nose cone? / side plate. Both should be easy fixes.

Anyway, after I clean it up, fix the selector and time/setup I am considering using it for purely binding or leather or maybe both. I started looking at Uwe's videos and will work with them when setting up.

Does anyone have information on this chandler? meaning is it a re-badge of a juki or a clone made by someone else?

Also, can anyone point me to pdf downloads of owners manual, service manual and parts manual?

Much appreciated!

Tom

-

On 4/2/2022 at 1:21 PM, suzelle said:Well some oil or grease where you need it is better than none, right? You can always clean it up and put another type in there. I use grease from my big embroidery machines in my sewing machines, and the oil too. I don't know if the oil is "Lily White" but it's clear for sure. Have had Lily White, also there is another brand that the zoom spout oilers have in them, also clear. I'd use the TriFlow grease too on gears if I had it on hand. Have read lots of good about that stuff. Oh, and a few years ago I tried something else.... a Reddish oil used in Auto Industry called "Marvel Mystery Oil"... I mixed it with my Lily White oil. I try different stuff, not afraid to experiment. One thing I won't do though, WD-40.

Thanks @suzelle! The tri-flow clear synthetic in both bottom and top gear casings. No problems so far, but I am now in the stages of timing machine and replacing some wear parts. So no real sewing per se, just running the machine a little to disburse the oil and grease.

I am following 2 - two hour YouTube’s from MTRC Crane on maintaining/setting up the machine. Got stuck earlier today with a stuck screw and @Jhunter13 helped me out with advice to unstick it. So I am back on track. His videos have 18 steps, I am on step 4 now.

-

1 hour ago, suzelle said:Found this from 2015

Thanks @suzelle! I have and use tri-flow oil and grease in my vintage domestics.

I refilled my lower grease box with tri-flow grease. Going to actually open the top grease box and re-fill with tri-flow grease today. I found the right screws to open it up.

I am leaning to just using regular Lily White sewing machine oil for the consew. It has been good for others for years and I am reluctant to put some other liquid into where it will go through the wicks. I am not sure how the wicks would react to that. It may be much ado about nothing, but nevertheless, I won’t have to worry about any wick issues with lily white.

-

I finally was able to order a bunch of parts for the machine from diamondneedle.com. They had all the parts. I called and spoke with someone there a few hours ago with my order. She confirmed that they were there and they put the order through on a Friday afternoon. Should be here early next week. I am only about 1.5 hours away from their actual place of business.

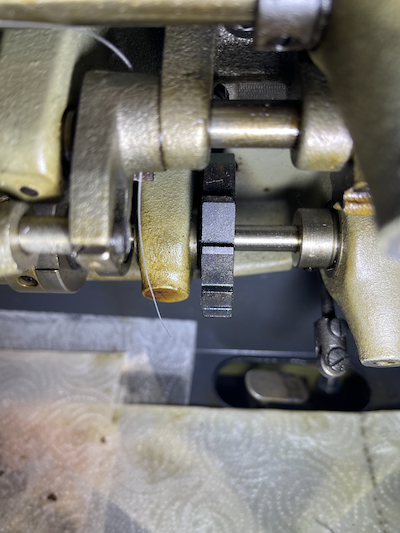

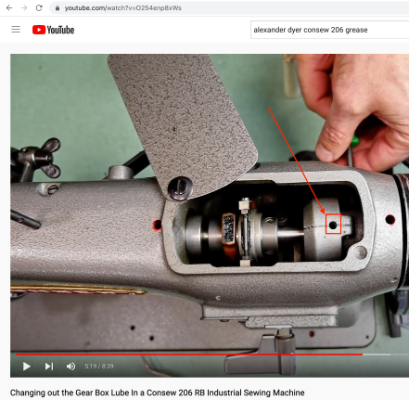

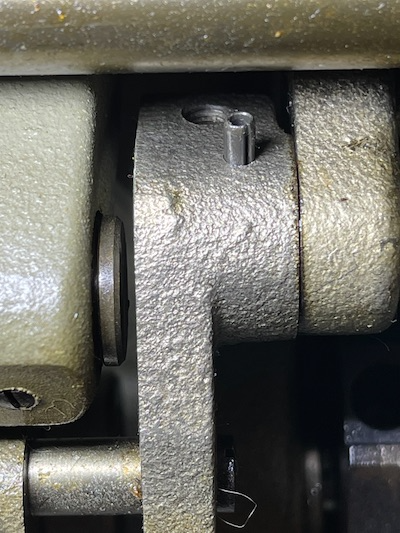

I am going to change the grease in the two "grease boxes" tonight or tomorrow, not sure of the technical name, but that is what I'll call them for now. I watched a youtube from Alexander Dyer https://youtu.be/O254enp8xWs and he goes into replacing the grease, but did not use any grease gun to totally fill the grease box.

I have two resized pictures of the "grease boxes".

I cannot help but to think that those 2 holes were put there so some type of grease gun could be used to fill with grease.

So, my latest question is this, once I change the grease, should I be "squirting" grease into those ports with a "grease gun" to ensure complete filling of the grease boxes?

FYI, I plan on using tri-flow clear synthetic grease. And my final question for this post, are there any reason NOT to use tri-flow clear synthetic grease?

-

31 minutes ago, suzelle said:Sojourner, did you order parts yet? I ordered, should be here tomorrow. They even had a dip stick (oil gauge) for my old Consew! Hope you find the parts you need too. How's it going? What size bobbins does your machine take? Asking because today I was told that my the Consew 255RB-2 and the 206RB-3 take the same size bobbin. I didn't know that. I have what is called their "Large" bobbin, equivalent to a "Style U" and the ones I bought on Ebay were close, but not exact. Jacksew/Sun Coast Sewing told me the ones they had on Ebay were not the same as the ones that come with the new 255RB-3 machines. They said make sure to call them and tell one of the Reps I want the ones that come with the new machines. They said something about the ones on Ebay being cheaper bobbins and agreed with me that they don't fit so good. Hmmm. Something to be aware of. I did order some from Diamond Needle already that look right, they come tomorrow. The Ebay ones are going back.

I did not order parts yet. I came down with a virus that set me back a few days. I plan on getting the machine set up in my work area this weekend before ordering. The bobbin winder looks like I might need to replace it too. And maybe a couple other small parts to have as backup. I want to find all I need before making an order.

the 206RB4 takes M bobbins. I think, from smaller to larger, the bobbins are G, M and U. @Jhunter13 has a juki LU-563 clone that takes U bobbins. He may have input for you with his experience on sourcing U bobbins.

I did order M bobbins and a set of presser feet from Amazon. The bobbins fit and do not bind when I am hand turning the machine. I have not sewed with them yet. From the seller, it looks like he liked the pre wound bobbin thread.

I try to stay away from eBay and sometimes Amazon when it comes to these parts. I wanted to order from sewingpartsonline, but they had some parts back ordered. And with them, it is a guessing game as to when parts will come in.

please let me know how your order from diamond needle goes. I’ll be putting an order in soon.

-

1 hour ago, suzelle said:sojourner, I just found that site too, https://www.diamondneedle.com/

I'm going to place an order too, was excited that it appears they have lots of Pfaff parts too!

Awesome! The place is a little over an hour away from me, but it does not look like they have a retail presence. Also, minimum $30 order. I am going to call them tomorrow to check on availability of parts I need.

good luck!

-

11 hours ago, sojourner999 said:I started the work on the 206RB-4. I took the upper tension assembly apart for cleaning. I found both tension discs has deep grooves where the thread goes through. I figure I would order the discs and a spring too.

i went to sewingpartsonline.com, they had discs and a spring, but are on back order. I did a search and could not find individual tension discs. I did find units on Amazon, but the bad reviews made me leery of ordering a complete unit.

Any recommendations on a vendor that has quality parts like tension discs and tension spring? Or is this something where I may have to order an entire unit? If so, where to get as close to OEM quality as possible?

Much appreciated.

I found diamondneedle.com. They sure do seem to have a plethora of parts, including the ones i need. There is a minimum $30 order. Does anyone have any input, either positive or negative, of ordering from diamondnedle.com ?

hx

-

I started the work on the 206RB-4. I took the upper tension assembly apart for cleaning. I found both tension discs has deep grooves where the thread goes through. I figure I would order the discs and a spring too.

i went to sewingpartsonline.com, they had discs and a spring, but are on back order. I did a search and could not find individual tension discs. I did find units on Amazon, but the bad reviews made me leery of ordering a complete unit.

Any recommendations on a vendor that has quality parts like tension discs and tension spring? Or is this something where I may have to order an entire unit? If so, where to get as close to OEM quality as possible?

Much appreciated.

Machine recommendation for best fwd/rev stitch matching

in Leather Sewing Machines

Posted · Report reply

I just wanted to share what worked for me. I would never have thought there was a solution unless I had the support of members here and for members youtube videos. Thanks all and special thanks to @Uwe!

-----

I still have the Consew 206RB-4 and am getting closer to selling it and getting a Seiko STH-8BLD-3 to replace it. I see that has instructions for matching stitch length.

I feel my never ending Odyssey of matching forward and reverse stitch lengths is coming to a close.

Now I have to find some light leather to start on my idea (pick pouch for a banjo) and/or tan a hide of the next deer I take (season doesn't start until the fall).

Thanks all!