-

Posts

152 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Teradee

-

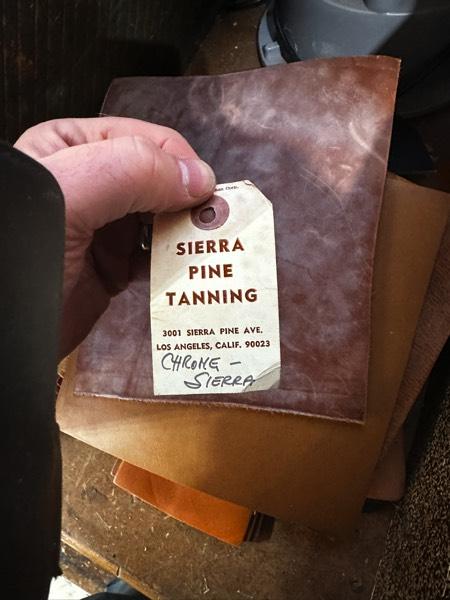

From the album: Leather Samples and Swatches

-

Hi everyone! I recently acquired a ton of leather samples and swatches...As always, it came with a story. Apparently the gentleman who had these passed away. His daughter said he was either a leather supplier, or leather buyer for Allen Edmonds (I live in SE WI down the road from their headquarters). His basement was full of boxes of this stuff. Here are my questions: I assume almost all of this stuff is chrome tanned, but I took tons of pics so if you have thoughts, let me know. Does anyone recognize the suppliers or tannery? Is the (what I assume is mold) easy to clean off and good as new?? Is this stuff easy to work with, and what would be some items you suggest making with this sort of leather? Anything else I should know about this type of thing? I think these things are really cool, and they'd be easy to practice on....but I also wanna make some cool stuff from it if I could! Also, I'd love info or history or stories about things like this. I assume these came from the 70s or 80s? a few pics below...and a link to many more here-----> Ok, enough for now but weigh in if you'd like!

-

Just a follow up to my post (based on some questions)... These are ALL cylinder arm machines.... but 4 have a flatbed attachment. You could also buy a flatbed for the one that doesn't have one. That means you can use these machines as a flatbed or a cylinder arm machine. I have the very same thing but in the Techsew 5100. It's a very handy little setup. I have never sewn with these machines (although I am keeping one of them), so I am selling as is. I can send lots of video/pictures so you know exactly what you are getting. These are essentially identical to the highly regarded Juki 441. That means you can easily find parts... pretty much anywhere. I am selling the heads only (but 4 come with the flatbed attachment). I have shipping boxes and am willing to ship, if you pay shipping costs. Hope that helps! Jason

-

I recently purchased (2) Ferdco Juki Pro 2000 heads....and (3) Ferdco Juki Pro 2000H heads. One of them looks 100% complete. The rest look to have missing shuttles or a cover plate missing here or there. (I can supply pics) 4 of these come with the flatbed table top. I'm told these are incredibly capable machines (can sew 7/8" of veg tan leather with extra heavy thread). These are the Juki models sold some time ago, but manufactured in Japan or Taiwan. I'm told they were the $5000-$6000 version. I don 't need them so I thought I'd try and sell them. These even come with the original shipping boxes (and can be shipped for a fee). I am in SE Wisconsin. I'm asking $800 each...and $1200 for the fully complete one. Please PM me if interested. Jason

-

Acquired a daily driver! (and then some)

Teradee replied to Teradee's topic in Leather Sewing Machines

Oh, for sure! Sorry @Northmount. I didn't begin this post as a "for sale" type of post. I was mainly trying to find some information and learn a little more. That said, I will definitely add those details in a post when I decide to sell these guys. (Hopefully soon and via a separate post). Does that work? Thanks! Jason -

Acquired a daily driver! (and then some)

Teradee replied to Teradee's topic in Leather Sewing Machines

I'm keeping one of them for sure. I can let you know when I figure out the pricing (or when I post on Facebook). I will likely be selling 3 or 4 of these dudes...and they are already packed up to ship! . Anyway, if interested, just PM me and I will reach out! - Jason -

Good morning! I have (finally) purchased a daily driver...a Techsew 5100 SE, and it’s incredible. It has everything I wanted on a machine. In the process of looking for the above machine, I met a guy near me (SE Wisconsin) who sold me a handful of his machines used in his business due to an impending retirement. They are the Ferdco Juki Pro 2000 machines. Most of them look great, and were working when I bought them. They even have the original Juki boxes! I'm sure there cleaning and tuning to do...and likely every single part isnt there...but these seem fairly indestructible... I'm going to keep a few, and sell a few. It seems like all the parts for the newer 441 clones fit these machines. I'm leaning toward NOT buying anything for them and just selling "as-is". These look to be the Japanese made models but was wondering if anyone knows if they were sold in the $5000-$6000 range? Or were these still in the $3000-$4000 range when new?

-

Hi all, I’ve read most of the Ferdco posts on the forum already but didn’t see anything related to the difference between the pro 2000 and the pro 2000 that has Juki print it below it. Does anyone know the difference and if the Jhuki version is good, better, or best in terms of their lineup?

-

Hi! Recently I made a beautiful notebook cover and it was going along nicely and after trimming and sanding, I realized I’m 1/8 short as I tried to test fit a notebook. what!? needless to say, I’m bummed. But this got me thinking…s there a way to add a closure or some other accoutrement that would fix my mistake and salvage this guy?

-

I have a foot press with a 5/8 course threaded bolt and receiver. The receiver fits a 9 mm or 3/8 shank. Instead of buying a bunch of new dies and anvils, I was thinking I could simply swap out the receiver base with a bolt that had an opening for a half inch shank. Outside of me, trying to make one, does anyone know where you can buy one reasonably priced?

-

I will definitely give these a try. The one thing that is odd is that when it catches the hand wheel, turns a little while the machine is not turning, which I assume would be the way it would get out of time quickly if I were using it. I will try the presser foot pressure and the screw to loosen it up a little bit and see how it goes!

-

Thanks @CowboyBob. I stayed up last night and fixed that part and was working on the timing as well. It's running pretty smoothly, but seems to be slightly binding from time to time as I turn the wheel. I'm assuming that is also a timing/alignment thing? I'll be digging in on that later today. Jason

-

Slightly different question but I have a second one 44W204 that is a single needle and the needle is hitting the hook when it spins around. Any idea what would cause that?

-

Thank you fellas! Great info! One follow up…how do I raise the needle bar as you suggested? I can dig in and figure it out, but thought I’d ask for advice (if I need it) before I give it a go. :-)

-

Good morning everyone, I have a few questions about a 145w204 I recently got running pretty good. This is a 2 needle machine. Is it ok to simply remove a needle and only use one needle if I want to see single stitches? If so, does it matter which side I choose? Second, this machine is very heavy duty. It will take needles from 22 to 27. Would that machine be reasonable to use for slightly more delicate operations (wallet interiors, etc) if I use a small needle and corresponding lighter thread? Or will it give me problems on the more delicate stuff? (I will try it out once I get some smaller needles but thought I’d see if someone had any experience). Thanks for considering and I hope everyone is having a good Monday! - Jason

-

Happy Friday! I have acquired a few foot press machines. Two of them have a screw with an adapter for anvils (9mm)...I circled the items in the first pic . The 3rd machine is a split rivet automatic feeding press. Does anyone know where to go physically buy anvils/setters for a foot press? Im in SE WI but my question is related to the "type" of store that might stock something like that? If not an actual store, online would help as well... Is there any advice on making or buying an adapter to use that would allow me to use the anvils sizes that are most often sold online? 9MM post seems like a very odd size for these... or am I wrong? Are there other types of anvils/setters I could buy for the machine in the second photo? It currently setup for split rivets. Any advice would be greatly appreciated! Jason

-

Yep - still have a few machines to sell, as well as some really nice tables. looking for anything in particular?

-

I just got one of my 204s working and put a servo on it and HOLY SMOKES!!! That thing is amazing! I put four layers of 6 oz veg tan down before I figured out the speed setting on the servo….and before I knew it, it sucked all four pieces through at lightning speed…with a relatively small stitch length…and it made perfect stitches! holy cow…don’t blink!

-

Hi! does anyone have advice on a good brand and shop to purchase needles for the 144w204? Also, is there a specific “leather” point option? Thanks! Jason

-

Thanks! Much appreciated

-

Hi! does anyone have recommendations for a pulley to use on my servo motor to slow it down even more? (Brand/size/where to purchase?) any help would be greatly appreciated!

-

yeah - ive battled in that tug of war a lot! . and ive learned once the knot is tucked into both sides and the stitch looks "correct" then i stop and just start sewing. Im currently using a brother ls2-b837

-

Please note - To give you an idea of what I'm open to do, here is a trade I made with another person who happens to live reasonably close. Value-wise, I think it was reasonable...But the big picture is that I need a few things, and I don't "need" anything in the list I sent. If you do...offer away! I gave him: 145w304 212g141 Singer 18-3 (I regret this one...it was my first machine ) Singer 31-15 Techsew 2900 Singer 111W155 (with some issues to fix) He gave me: Brother LS2-B837 Singer 29-4 Cobra NP-4

-

yessir! but i have to be totally honest here....i fiddle with everything so much to get everything "dialed in"...the split second the stitch "looks right", I forbid my kids from breathing on or near the sewing machine until im done. Sometimes the bobbin passes the drop test...sometimes its loose. If it looks correct, I dont change it. Sooooo...would that cause sub-par stitches or snug stitches perhaps? (snug meaning nice, secure stitches)

-

Hi all, I mentioned a while ago a few machines I was given as part of a shop closing. Well, I have a final list I thought I'd post to see if anyone wanted to buy one or some of these...or (even better for me) you have some items I need and would TRADE. As you might guess, I am an entry level hobbyist in leather and don't sell ANYTHING. I make stuff for me and family/friends. I could argue I need NOTHING on this list, and my wife often argues this very point. Some of these were given to me, so I'm happy to "pay it forward" if possible. These machines are currently at our home in Northern Indiana / Elkhart area. I will be grabbing them in the next few weeks and bringing them to SE Wisconsin / Milwaukee. I don't really want to ship these...but could look into it (or you could arrange it). Here is the list of machines. PM me and I can share photos and further detail. (All of these have tables and motors) Brother LK3-B439 Singer 112w139 Juki DDL-5550-6 Singer 145wsv27 Singer 144w204 Singer bartack Singer bartack Singer bartack Reece button hole machine Wilcox & Gibbs Serger Wilcox & Gibbs Serger Wilcox & Gibbs Serger Singer 145w304 Singer 145w304 Singer 145w304 Singer 145w204 Singer 212g140 (no reverse) Singer 112w140 Ace automatic strap cutter (fabric) Here are some things I need. To get these, I'm happy to "bundle" some of these and try and make the deal one-sided (in your favor!). A Quality STRAP CUTTER - (this doesn't have to be a machine, although thats preferred..it could be a plough or draw guage, but heavy duty/high quality) A Quality SPLITTER ONE awesome "daily driver" machine that sews medium to heavy leather with thread up to 207 Thanks! Jason (ps - this is an incredibly helpful site, and the community built around it, and the administrators of the community and site, are so awesome! Thanks for everything you all do!)